Heat exchanger capable of effectively preventing incrustation scale hazard

A heat exchanger and scaling technology, applied in the field of thermal energy equipment, can solve the problems of increased investment, increased over time, reduced efficiency, etc., to achieve the effect of preventing fire overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be used in steam generators, water heaters and water boilers, and this embodiment takes the steam generator as an example.

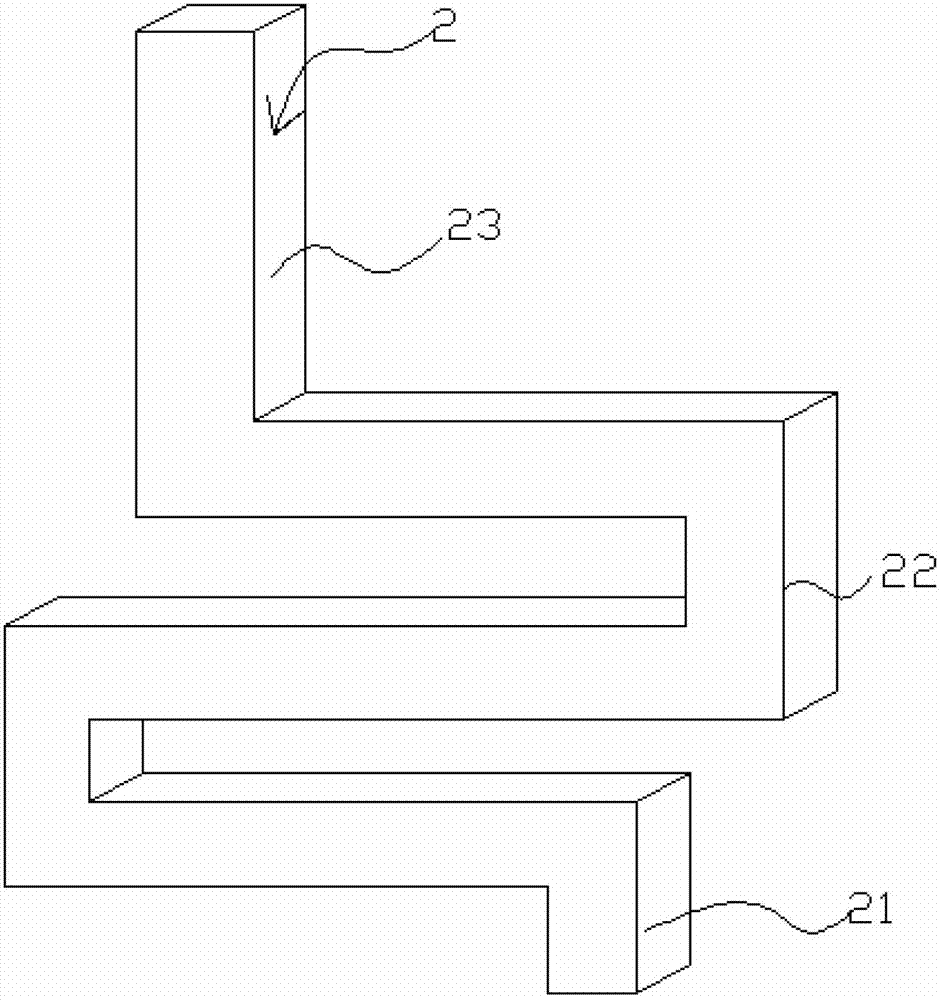

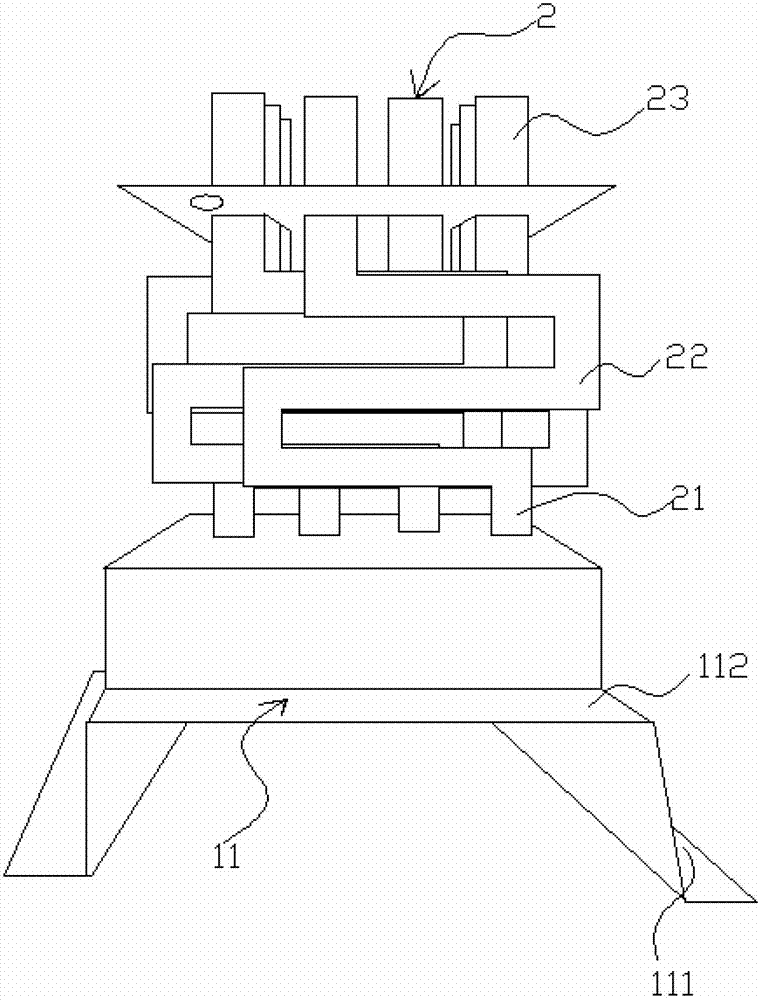

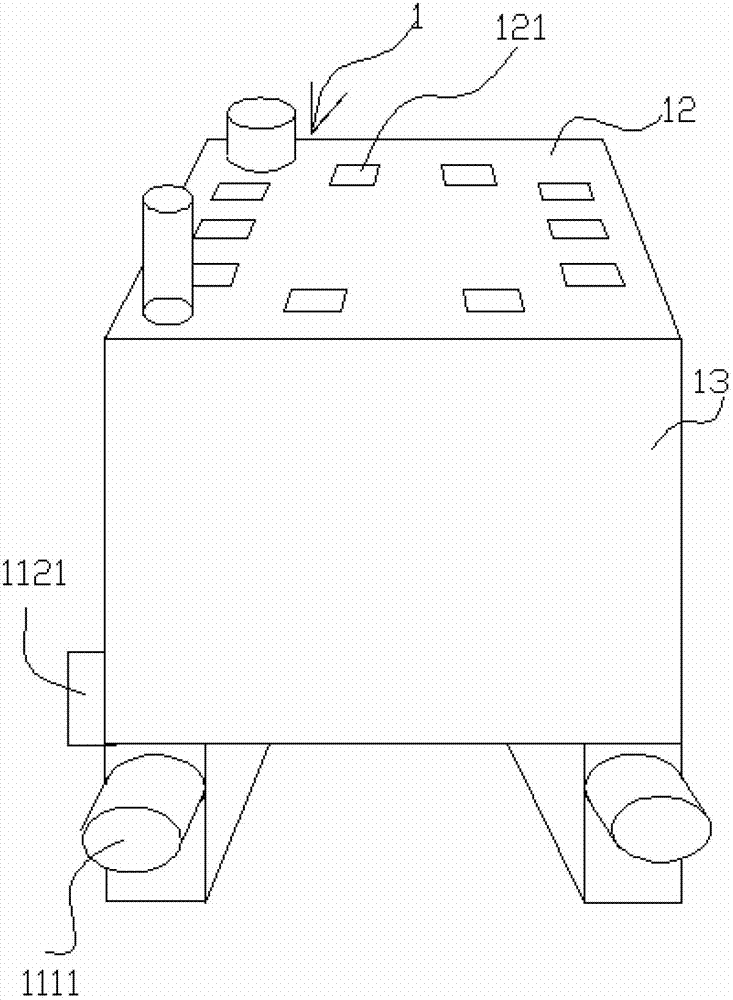

[0022] Such as Figure 1-4 As shown, the heat exchanger includes a shell 1 and a fire tube 2 arranged in the shell 1. The cross-sectional shape of the fire tube 2 is square, the lower part of the fire tube 2 is a vertical fire inlet 21, and the middle part of the fire tube 2 is curved. The heat exchange part 22, the fire tube 2 top is a vertical fire outlet 23. The heat exchanger 1 includes a bottom tank 11 , a top plate 12 and four side plates 13 . The cross-sectional shape of the bottom kettle 11 is an upside-down water tank. The protruding two sides of the bottom kettle 11 and the side plates 13 form two first scale storage tanks 111. One end of the first scale storage tank 111 is provided with a first scale discharge port 1111. The bottom end of the middle part of the dirt storage tank 111 is provided with a dirt an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com