Pneumatic paste filling machine

A filling machine and paste technology, applied in packaging, liquid materials, packaging protection, etc., can solve the problems of no feeding, difficult movement, easy damage or loss, etc., to prevent paste precipitation or condensation, and improve product quality , the effect of preventing material breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

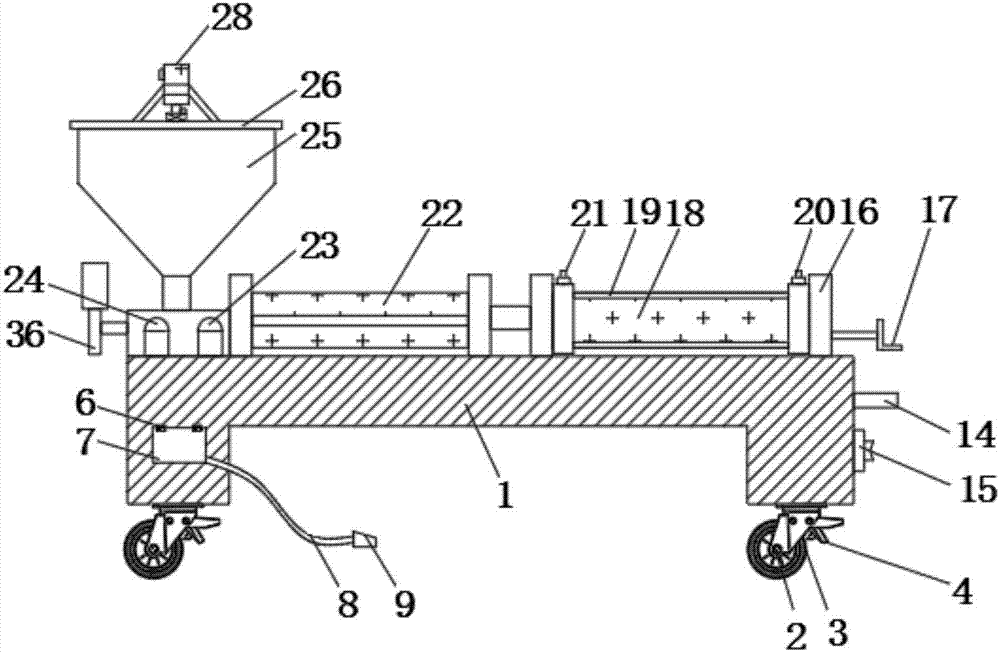

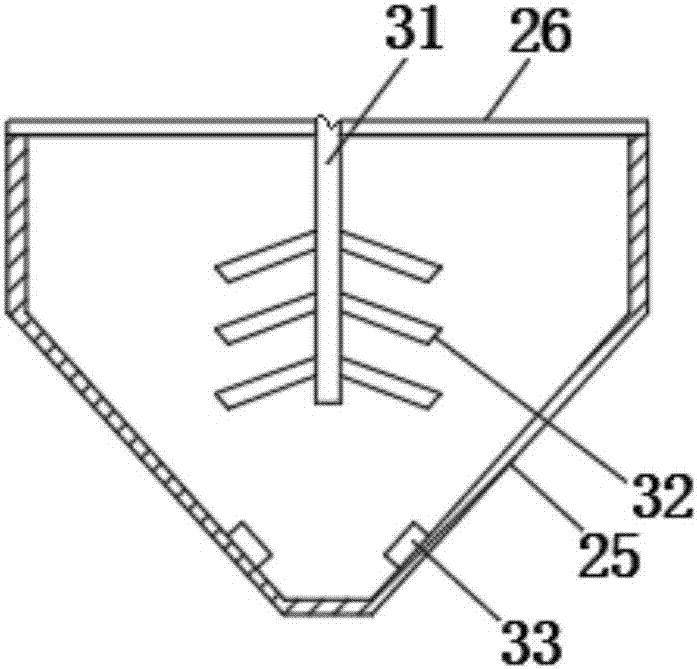

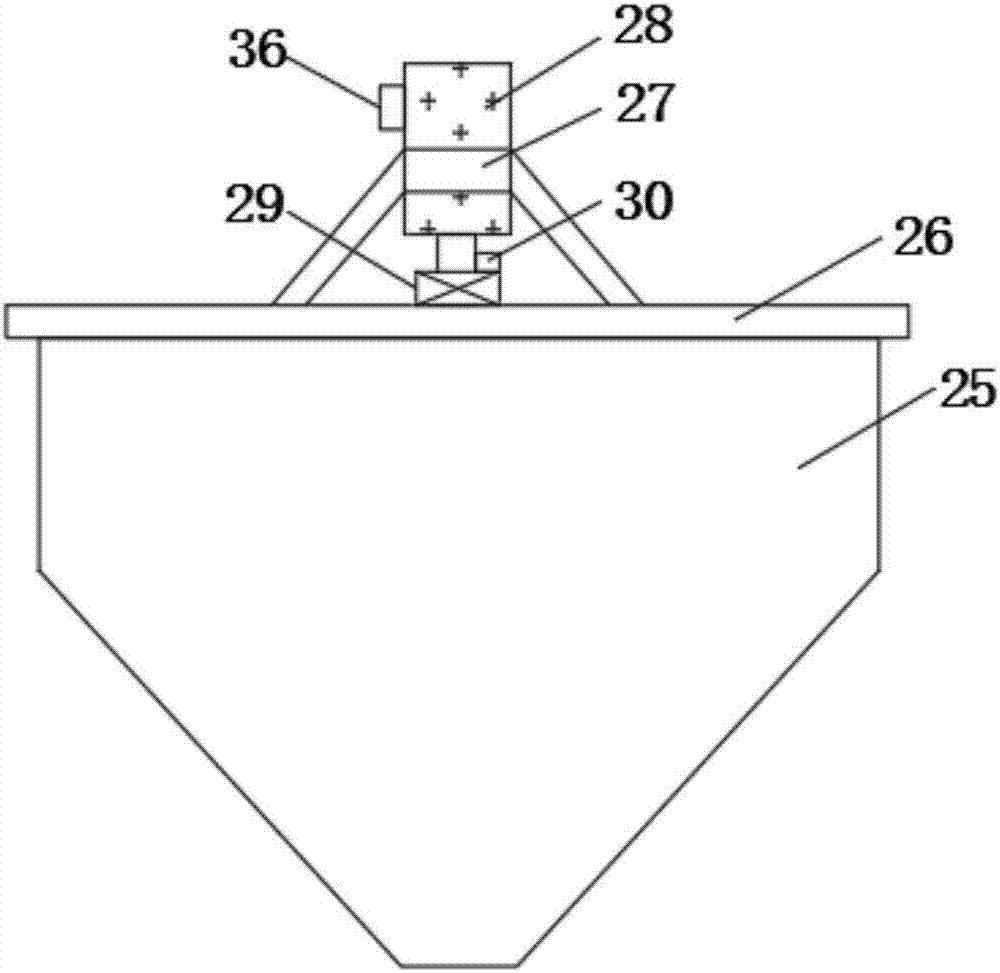

[0022] see Figure 1-5 , the present invention provides a technical solution: a pneumatic paste filling machine, including a base 1, a fixed shaft 2, a pulley 3, a brake lever 4, a storage slot 5, a first hinge 6, a sealing cover 7, and a wire 8 , foot switch 9, shock-absorbing bottom plate 10, shock-absorbing top plate 11, spring limit post 12, shock-absorbing spring 13, air inlet 14, power switch 15, fixed frame 16, quantitative handwheel 17, cylinder 18, fixed thread Rod 19, suction speed regulator 20, feeding speed regulator 21, metering tube 22, first alarm 23, second alarm 24, storage hopper 25, end cap 26, motor frame 27, stirring motor 28, Coupling 29, disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com