Mechanical pressure slide block and bulb lead screw connecting device

A technology of mechanical presses and connecting devices, applied in the field of mechanical presses, can solve problems such as abnormal mechanism operation, low efficiency, troublesome adjustment process, etc., and achieve the effects of avoiding inconvenience and trouble, high efficiency, and avoiding abnormal wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

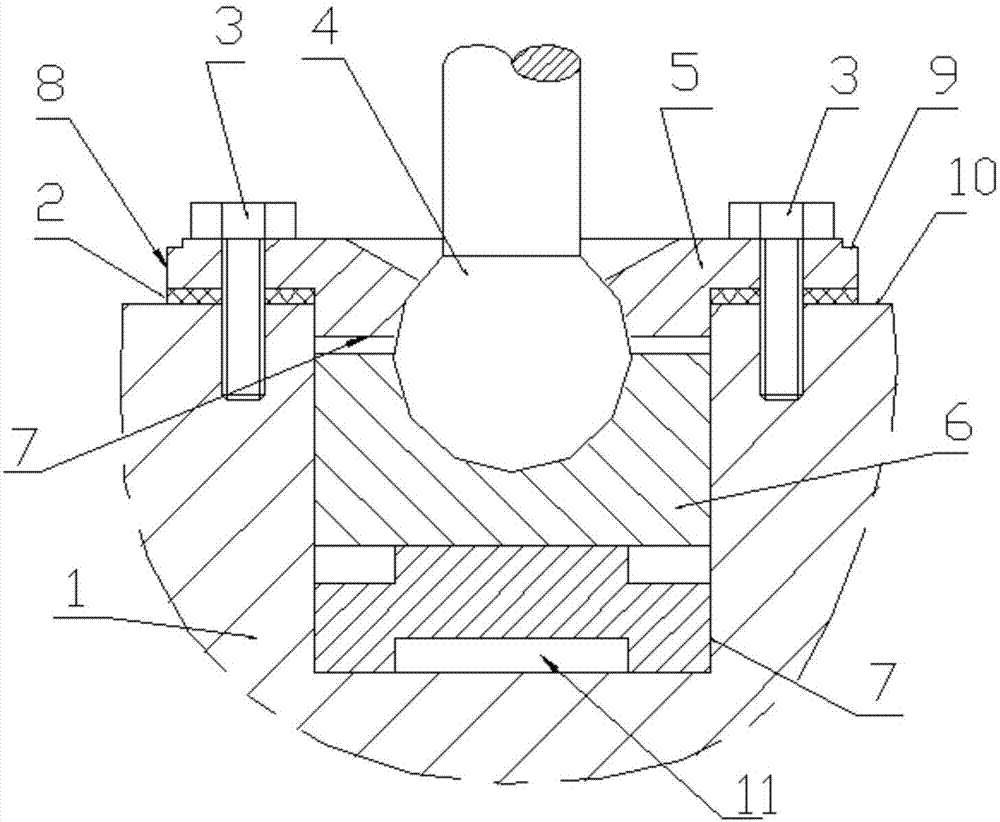

[0008] combined with figure 1 , the specific embodiment of the present invention is:

[0009] The connecting device between the slider and the ball screw of a mechanical press includes a slider (1), and a blind hole (11) with an upward mouth is formed on the middle position of the slider (1), The bottom of the blind hole (11) is provided with a crushing safety device (7), and a ball bowl seat (6) is provided in the blind hole (11) on the upper part of the crushing safety device (7), The ball joint part of the ball screw (4) is set in the spherical pit of the ball bowl seat (6), and the ball cover (5) is sleeved on the ball screw (4) through its middle hole, The seam (7) of the ball head cover (5) is matched with the upper part of the blind hole (11), and the flange (8) of the ball head cover (5) is in contact with the upper plane of the slider (1) There is a spacer (2) in the middle, and the bolt (3) passes through the through hole on the flange (8) plane of the ball head co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com