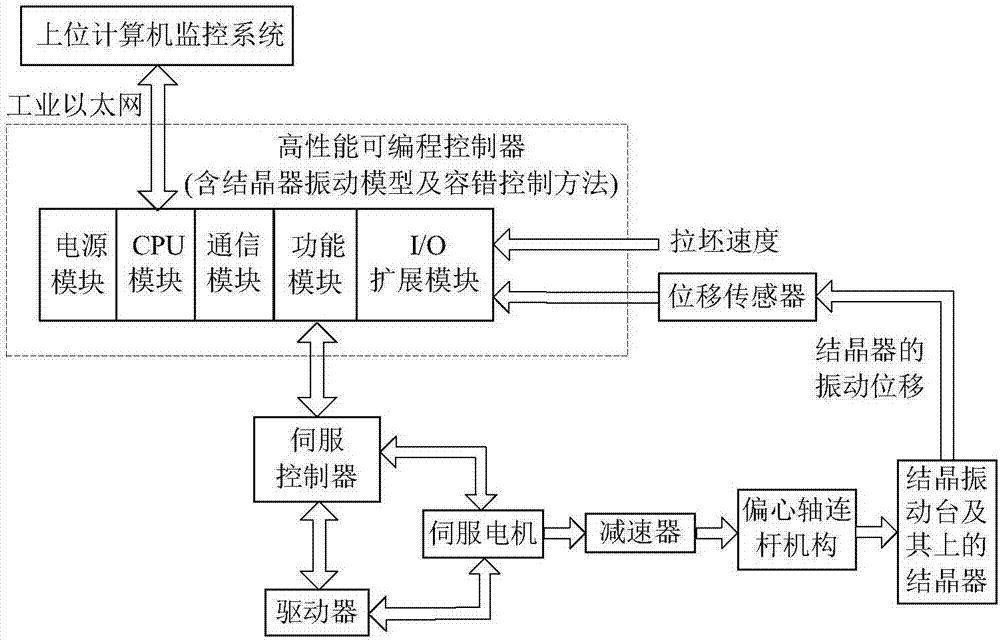

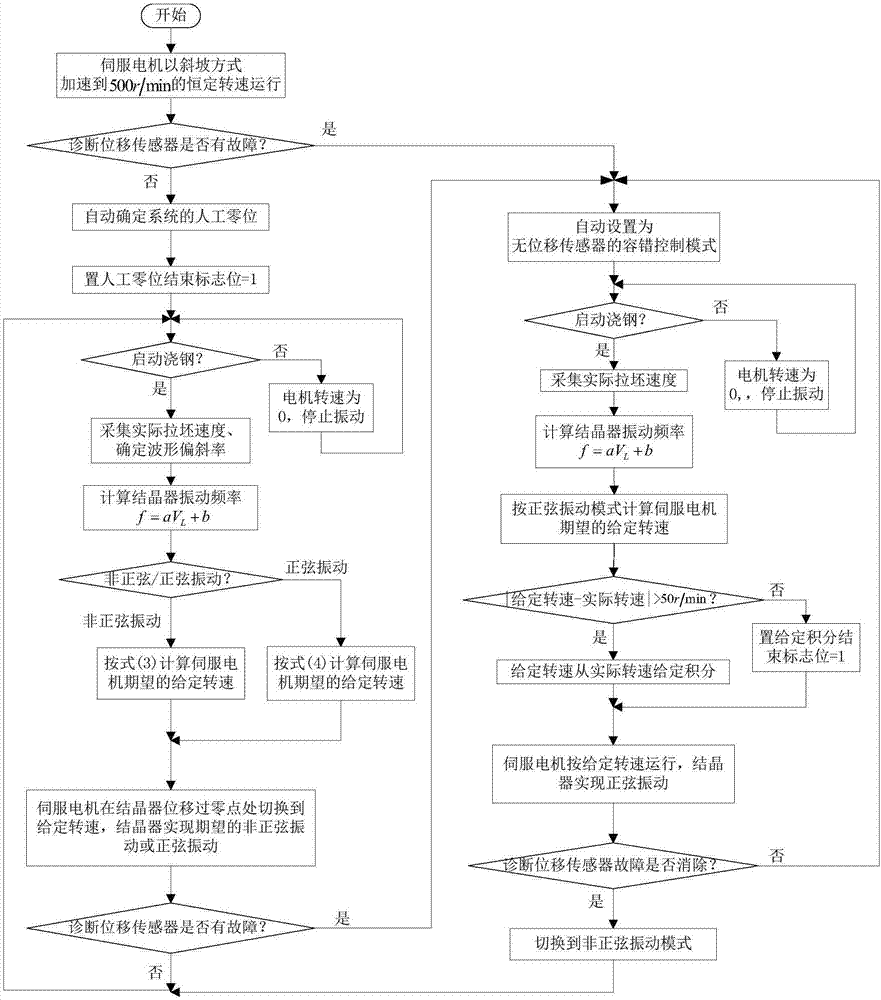

Fault-tolerant control device and method for non-sinusoidal oscillation of continuous casting crystallizer driven by servo motor

A mold vibration and continuous casting mold technology, applied in the field of continuous casting, can solve problems such as breakout, influence on billet quality, abnormal production, etc., and achieve the effect of real-time and smooth switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Example: A full-arc billet continuous casting machine mold in a steel plant casts 165*165 slabs, and the non-sinusoidal vibration of the mold is used. The expected displacement given waveform S(t) and speed given waveform V( t) are:

[0020] s(t)=h sin(ωt-A sin(ωt)) (1)

[0021] V(t)=hω(1-A cos(ωt))cos(ωt-A sin(ωt)) (2)

[0022] In the formula, ω=2πf / 60 is the average angular velocity of the eccentric shaft, and the crystallizer vibration frequency f=aV L +b, process parameter a=65.5, b=14.5, unit is times / min, casting speed V L (m / min), crystallizer vibration amplitude h=4mm; parameters α is the waveform deflection rate, and its value ranges from -0.4 to +0.4. When α=0, the crystallizer vibration displacement curve is a sinusoidal curve, and the crystallizer vibrates sinusoidally.

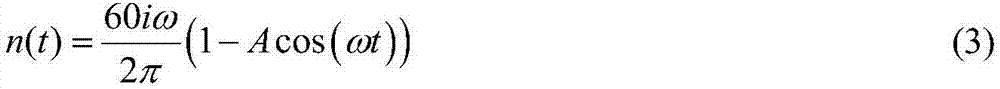

[0023] Under the ideal condition of not considering the nonlinearity and uncertainty of the transmission mechanism such as clearance and friction, the expected rotational speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com