Brittle material acid pickling frame

A brittle material, pickling technology, applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of surface cleanliness of parts, difficult to master the process, easy to damage parts, etc., to achieve cleaning The time is consistent, the cleaning effect is good, and the cleaning effect is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

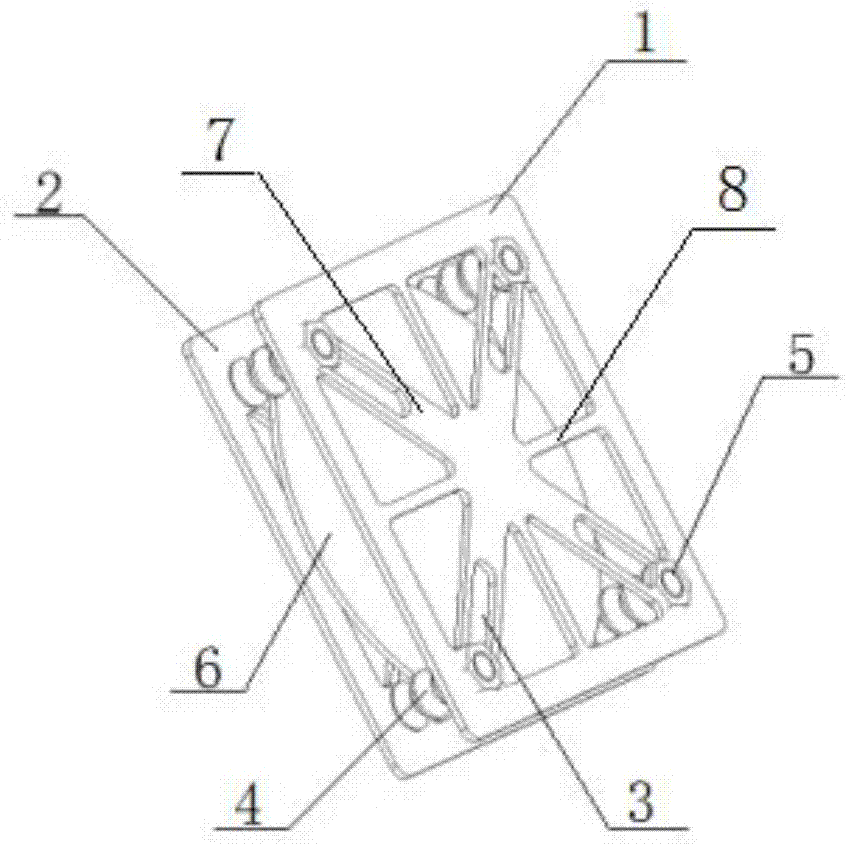

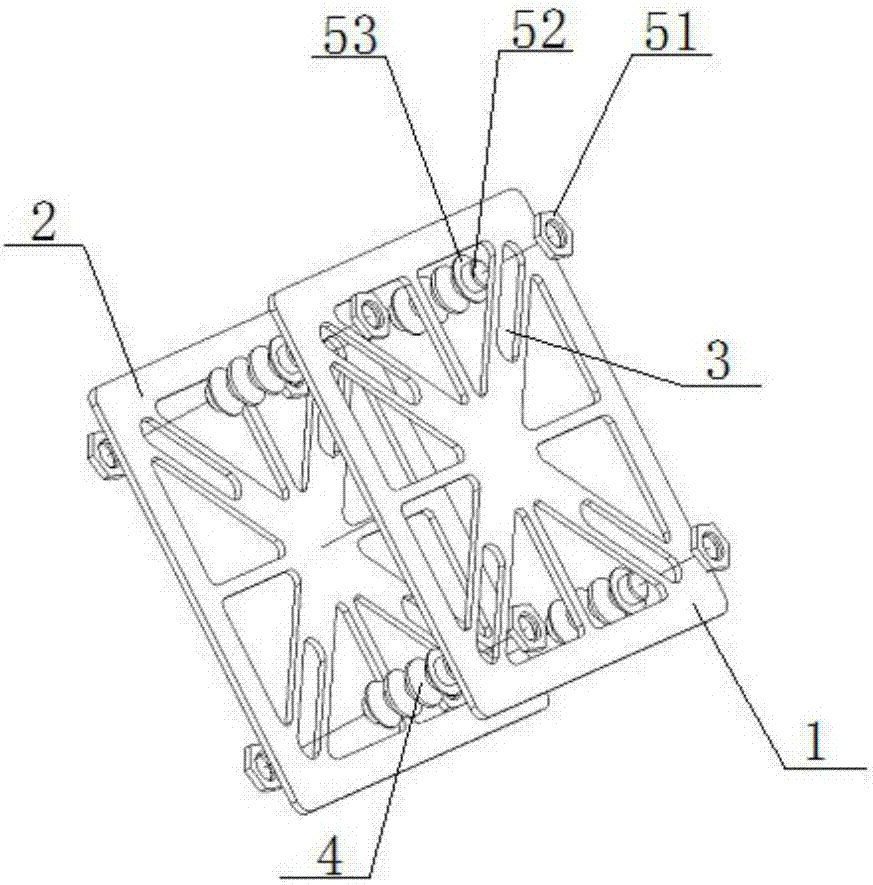

[0018] Such as Figure 1-2 , including two rectangular front support frames 1 and rear support frames 2, the front support frame 1 and the rear support frame 2 are placed in parallel and at intervals, and four fixing rods 4 are vertically arranged between the front support frame 1 and the rear support frame 2, The two ends of the fixed rod 4 are slidably connected to the front support frame 1 and the rear support frame 2 respectively, and the sliding routes of the ends of the fixed rod 4 connected with the front support frame 1 are respectively arranged from the center of the front support frame 1 to the four top corners. On the four connecting lines, the sliding routes of the ends of the fixed rod 4 connected to the rear support frame 2 are respectively arranged on the four connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com