Dry powder fire extinguisher achieving automatic spraying

A fire extinguisher and dry powder technology, which is applied in fire rescue and other fields, can solve the problems of easy damage, cost and complex structure, and achieve the effects of avoiding agglomeration, improving efficiency and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

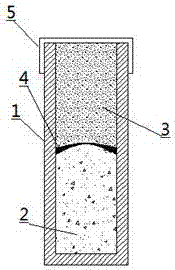

[0020] The present embodiment provides a kind of dry powder fire extinguisher that sprays automatically, as figure 1 , including a columnar, hollow metal shell 1, the top of the metal shell 1 has an injection port; the bottom of the metal shell 1 is filled with an expansion agent layer 2, and the space between the expansion agent layer 2 and the injection port is filled with ABC fire extinguishing dry powder Layer 3; a latex film 4 is separated between the expansion agent layer 1 and the ABC fire extinguishing dry powder layer 3; the edge of the latex film 4 is adhered to the inner wall of the metal shell; the injection port is covered with a metal foil 5 (the metal foil is bonded agent adhesion).

[0021] Further the thickness of the latex film increases from the center towards the edges.

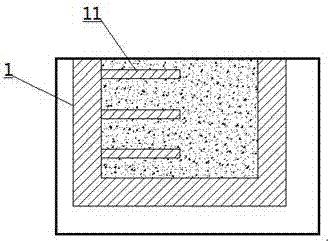

[0022] In another preferred embodiment, as figure 2 , a plurality of metal heat conducting fins 11 protrude from the inner wall of the metal shell in the area below the latex film.

Embodiment 2

[0024] This embodiment provides an automatic injection dry powder fire extinguisher, the structure of which is as in Embodiment 1. In particular, the expansion agent layer in this embodiment is made of sodium bicarbonate powder.

Embodiment 3

[0026] This embodiment provides an automatic injection dry powder fire extinguisher, the structure of which is as in Embodiment 1. In particular, the expansion agent layer in this embodiment is made of sodium bicarbonate powder. The expansion agent layer also includes activated carbon powder, copper sulfate pentahydrate powder, citric acid powder, and the mass ratio of activated carbon powder, sodium bicarbonate powder, copper sulfate pentahydrate powder, and citric acid powder is 1:7:6:7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com