Preparation method of sheepskin collagen casing

A collagen casing and sheepskin technology, which is applied in sausage casings, slaughtering, food science, etc., can solve the problems of unsatisfactory practical application and unsatisfactory properties of sheepskin collagen casings, and achieve superior barrier performance, fine and uniform taste, huge economic benefits and social benefits benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

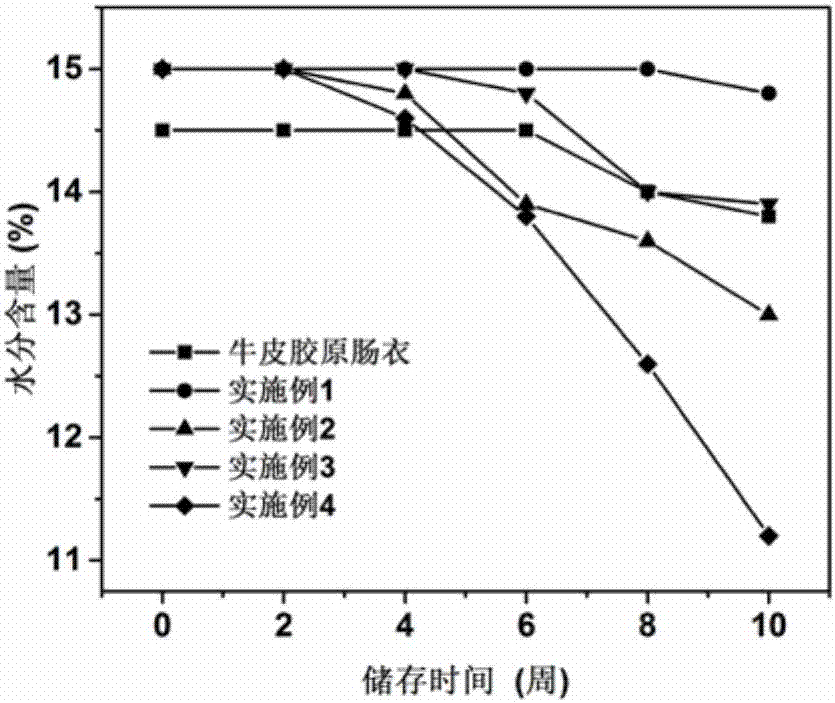

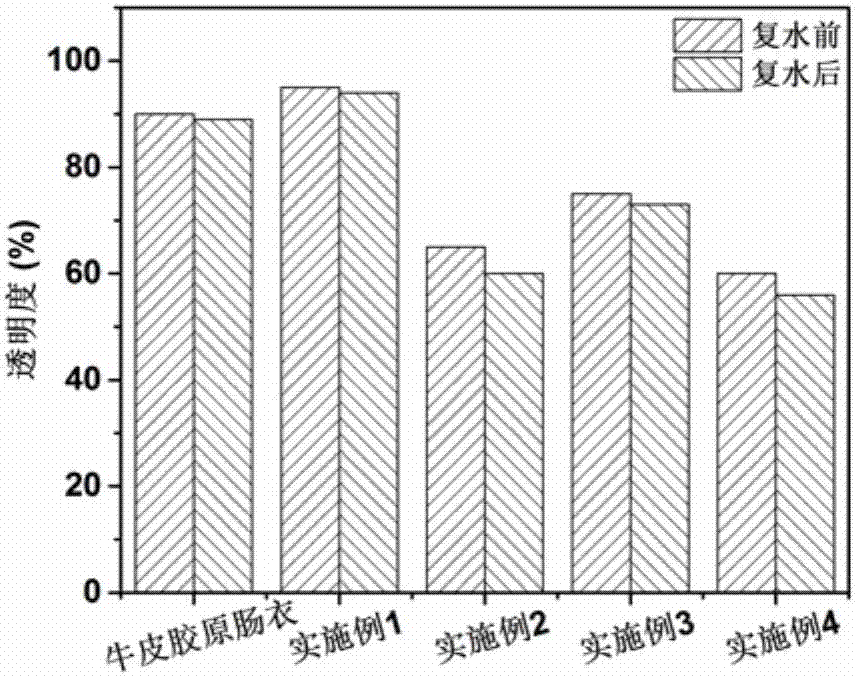

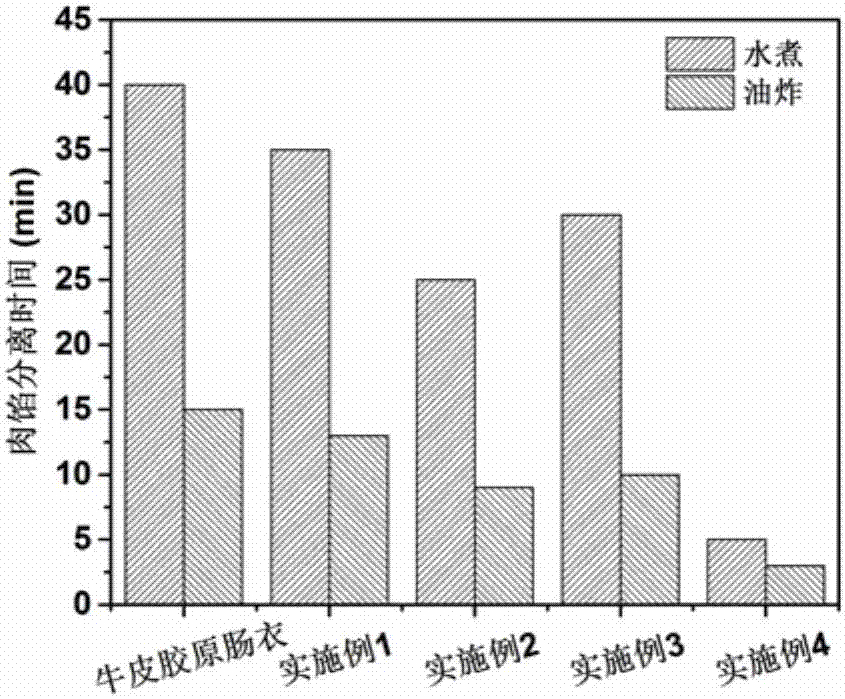

[0033] Combined use of hydrogen peroxide and ultraviolet treatment to prepare sheepskin collagen casings, the process route is as follows: the raw sheepskin is cleaned by soaking in water, liming and depilation, hydrogen peroxide treatment, first pickling, mincing and beating, compounding, secondary acidification, homogeneous filtration, extrusion The sheepskin collagen casings were prepared by curing, washing and plasticizing, ultraviolet cross-linking and drying and humidifying.

[0034] The specific steps are:

[0035] (1) Raw sheepskin soaked in water for cleaning: Rinse the raw leather with grass thorns and hair with clean water until there is no sand in the leather water, soak in clean water at 15°C for 3 days, and change the water every 6 hours.

[0036](2) Liming and hair removal: 5% lime, 3% sodium sulfide and 10% water were mixed into a paste, evenly spread on the soaked sheepskin, and the hair was removed for 3 hours. Wash the sheepskin 4 times with water, soak it ...

Embodiment 2

[0048] In order to highlight the advantages of combined hydrogen peroxide and ultraviolet treatment, the hydrogen peroxide treatment in Example 1 is omitted to prepare sheepskin collagen casings. The process route is as follows: the raw sheepskin is washed by immersion, liming and depilation, peeling, pickling once, crushing and beating, and then Sheepskin collagen casings were prepared through compounding, secondary acidification, homogeneous filtration, extrusion curing, washing and plasticizing, ultraviolet crosslinking and drying and humidification.

[0049] The specific steps are:

[0050] (1) Raw sheepskin soaked in water for cleaning: Rinse the raw leather with grass thorns and hair with clean water until there is no sand in the leather water, soak in clean water at 15°C for 3 days, and change the water every 6 hours.

[0051] (2) Liming and hair removal: 5% lime, 3% sodium sulfide and 10% water were mixed into a paste, evenly spread on the soaked sheepskin, and the hai...

Embodiment 3

[0064] In order to highlight the advantages of combined hydrogen peroxide and ultraviolet treatment, omit the ultraviolet crosslinking treatment in Example 1 to prepare sheepskin collagen casings. The process route is: the raw sheepskin is washed by immersion, liming and depilation, hydrogen peroxide treatment, pickling once, minced Beating, compounding, secondary acidification, homogeneous filtration, extrusion curing, washing and plasticizing, drying and humidifying to obtain sheepskin collagen casings.

[0065] The specific steps are:

[0066] (1) Raw sheepskin soaked in water for cleaning: Rinse the raw leather with thorns and hair with clean water until there is no sand in the leather water, soak in clean water at 15°C for 3 days, and change the water every 6 hours.

[0067] (2) Liming and hair removal: 5% lime, 3% sodium sulfide and 10% water were mixed into a paste, evenly spread on the soaked sheepskin, and the hair was removed for 3 hours. Wash the sheepskin 4 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com