Old cable intelligent recovery device

A recycling device and old cable technology, which is applied in the direction of cable installation device, cable installation, electronic waste recycling, etc., can solve the problem of inability to completely separate the cable conductor and cable insulation, inability to realize online peeling, increase the workload of recycling, etc. problems, to achieve the effect of facilitating reuse, reducing occupation and pollution, and reducing the difficulty of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

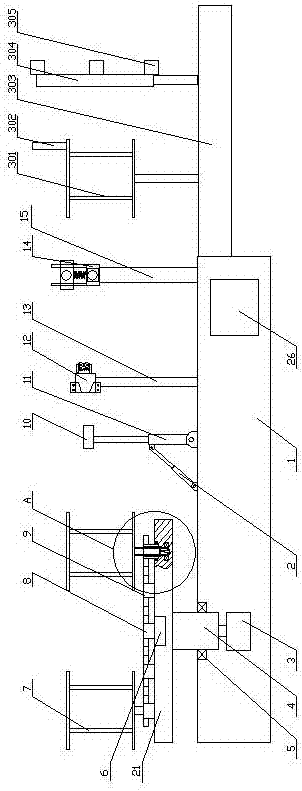

[0049] An intelligent recycling device for old cables, comprising a base 1, a winding mechanism arranged on the base 1, three lead mechanisms arranged on the base 1 and matched with the winding mechanism, arranged on the base The peeling mechanism on 1 and matched with the three lead mechanisms, the guide mechanism provided on the base 1 and matched with the peeling mechanism, and the side of the base for coordinating control of the retracting mechanism. Control mechanism 26 of the coil mechanism, the lead mechanism, the peeling mechanism and the guide mechanism;

[0050] The base 1 is provided with a screening mechanism that is signally connected to the control mechanism 26 on the side where the guiding mechanism is provided. Four CCD cameras 305 are evenly arranged on the 304, and the CCD cameras 305 face the center of the mounting frame 304. Between the mounting frame 304 and the guiding mechanism, a rotary setting reel 301 is set on the identification table 303, The upper...

Embodiment 2

[0068] The difference between it and the first embodiment is:

[0069] A guide plate 129 is provided on the annular blade holder 124 for guiding the outer skin.

[0070] The upper half of the lead rod 11 is provided with a third telescopic rod.

[0071] The telescopic rod 22 is an electric telescopic rod with a rotary joint 23 arranged at the lower part, and a brush is provided at the lower end of the electric telescopic rod.

[0072] The guide plate used in this embodiment is a rectangular slot, which can well control the cut outer skin, avoid the phenomenon of disorder, and achieve more precise length control. The third telescopic rod used is an electric telescopic rod. When the lead wire is wound, the retraction of the third telescopic rod can control the winding position of the outer skin or the metal wire core, so as to ensure the maximum utilization of the winding wheel, reduce the frequency of unloading, and improve the work efficiency.

Embodiment 3

[0074] like Figure 10-12 As shown: the difference from the second embodiment is that: the rotating platform 21 is provided with four first positioning protrusions 28 for positioning, and the base 1 is provided with a first protrusion 28 matching the first protrusions 28 a positioning switch 31, and the first positioning switch 31 is signal interconnected with the control mechanism 26;

[0075] Four second positioning protrusions 29 for positioning are provided on the lower end surface of the winding wheel, and a second positioning switch 30 is provided on the rotating platform 21 to match the second positioning protrusions 29, and The second positioning switch 30 is signal interconnected with the control mechanism 26 .

[0076] The first positioning protrusion and the second positioning protrusion used in this embodiment are both quadrangular platforms; and the first positioning protrusion used can also be arranged on the rotating platform, and the protrusion is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com