Dynamic simulation experiment device for anti-rust property and antifouling property of marine equipment surface coating

A surface coating and marine equipment technology is applied in the field of dynamic simulation experimental devices for the rust and antifouling capability of marine equipment surface coatings, which can solve problems such as deformity, chemical corrosion, affecting the development and utilization of marine resources, etc., and achieves simple structure and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

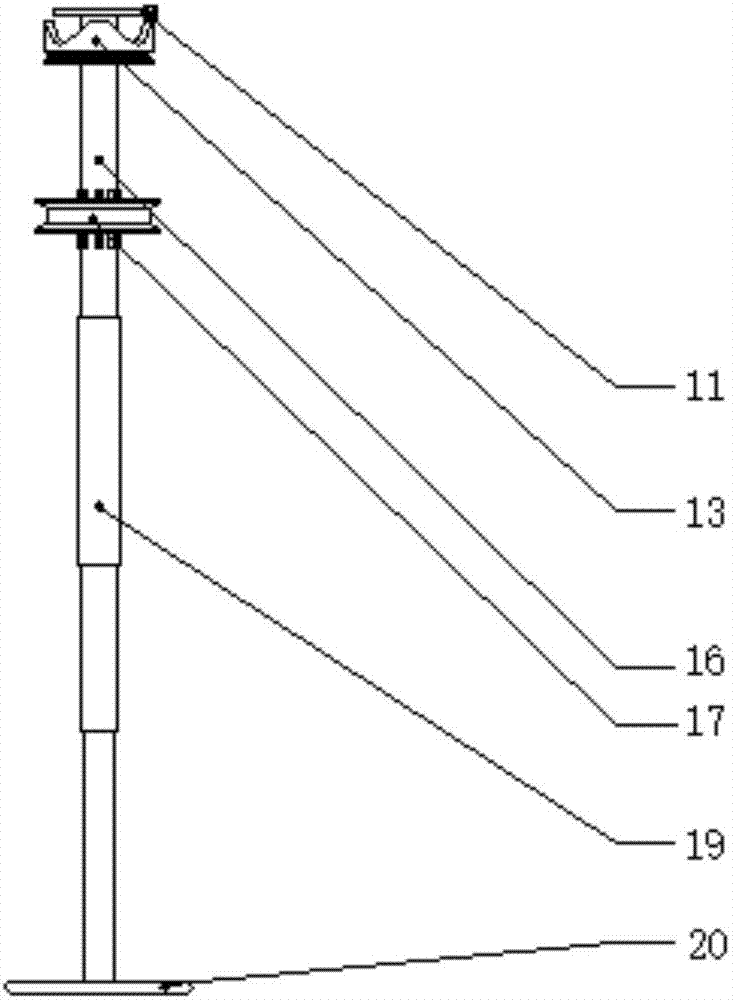

[0048] The invention provides a dynamic simulation experiment device for anti-rust and anti-pollution ability of surface coatings of marine equipment, such as figure 1 With the structure shown, the device is small in size, high in flexibility, easy to fix and operate, high in precision, fast in response, flexible in structure, small in space, low in manufacturing cost, and can be widely promoted.

[0049] like figure 1 and figure 2 The dynamic simulation experiment device for anti-rust and anti-fouling ability of surface coatings of marine equipment shown includes fixing and supporting devices, power devices, telescopic devices and sensing devices.

[0050] The fixing and supporting device comprises a base 1 and a main support bar 3 fixed on the base 1 by a bearing 1, a hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com