Manufacturing method of piezoelectric crystals

A technology of piezoelectric crystals and manufacturing methods, which is applied in the field of manufacturing surface acoustic wave filters, can solve problems such as inability to grow yields, lack of market competitiveness, etc., to save subsequent annealing processes, reduce process steps and energy consumption , the effect of low degree of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of manufacturing method of piezoelectric crystal, described piezoelectric crystal is lithium tantalate crystal, specific process is as follows,

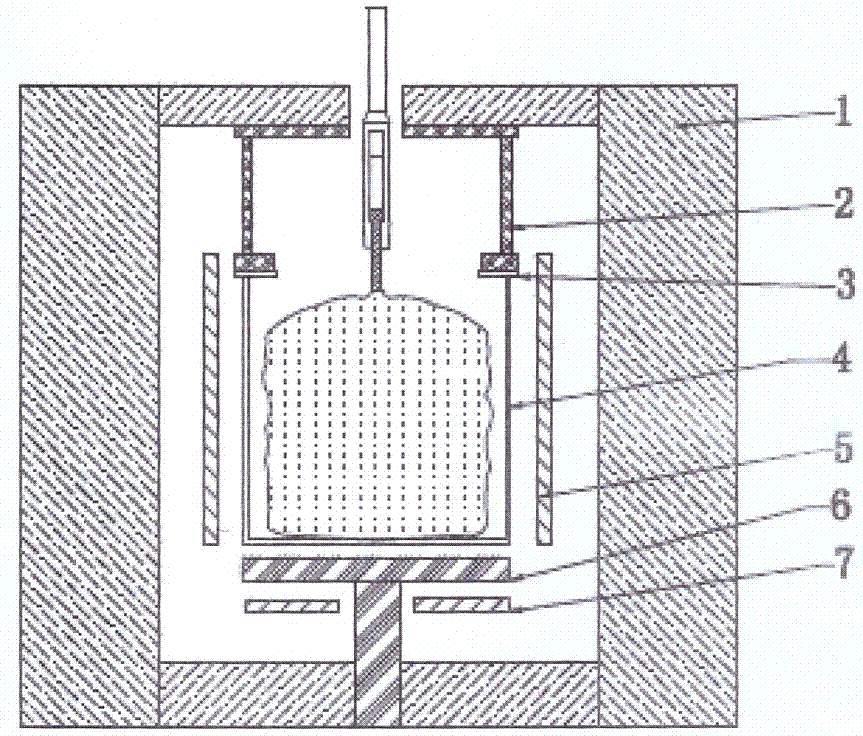

[0028] (1) Thermal field assembly: install the thermal field in sequence (as attached figure 1 shown), and at the same time fill the iridium crucible with 36kg of lithium tantalate raw material;

[0029] (2) Heating and melting: the iridium crucible is heated by resistance heating, and the temperature in the crucible is heated to above 1650°C in about 15 hours, and the lithium tantalate raw material is melted into a molten soup;

[0030] (3) Seeding: Adjust the output power of the main heater, the liquid surface temperature is 1650 ℃ ~ 1660 ℃, form a stable thermal convection, keep the constant heating output power for more than 5 hours, so that the molten soup is in a thermally stable state, and the convection center is positive Lithium tantalate seed crystals in the X direction are placed above, so that...

Embodiment 2

[0036] Embodiment 2: the manufacturing method of the second piezoelectric crystal, the piezoelectric crystal is an iron-doped lithium tantalate crystal, the specific process is as follows,

[0037] (1) Thermal field assembly: Install the thermal field in sequence, and at the same time fill the iridium crucible with 36kg of iron-doped lithium tantalate raw material;

[0038] (2) Heating and melting: The iridium crucible is heated by resistance heating, and the temperature in the crucible is heated to above 1650°C in about 15 hours, and the raw material of iron-doped lithium tantalate is melted into a molten soup;

[0039] (3) Seeding: Adjust the output power of the main heater, and the liquid surface temperature is between 1650°C and 1660°C to form a stable heat convection. Keep a constant heating output power for more than 5 hours, so that the molten soup is in a thermally stable state. Put the lithium tantalate seed crystal in the X direction from directly above the convection...

Embodiment 3

[0046] Embodiment 3: the manufacture method of the 3rd kind of piezoelectric crystal, described piezoelectric crystal is lithium niobate crystal, and specific process is as follows,

[0047] (1) Thermal field assembly: install the thermal field in sequence, and fill 23kg of lithium niobate raw material into the iridium crucible at the same time;

[0048] (2) Heating and melting: the iridium crucible is heated by resistance heating, and the temperature in the crucible is heated to above 1260°C in about 12 hours, and the lithium niobate raw material is melted into a molten soup;

[0049] (3) Seeding: Adjust the output power of the main heater, and the liquid surface temperature is between 1260°C and 1270°C to form a stable heat convection. Keep a constant heating output power for more than 5 hours, so that the molten soup is in a thermally stable state. Put the lithium niobate seed crystal in the Z direction from directly above the convection center, make the seed crystal conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com