Internal flow grille for sewage treatment, use method and sewage treatment equipment thereof

A sewage treatment equipment and sewage treatment technology, applied in water/sewage treatment equipment, water/sewage treatment, water/sludge/sewage treatment, etc. Cleaning and other issues, to achieve the effect of convenient on-site operation, stable water flow capacity, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

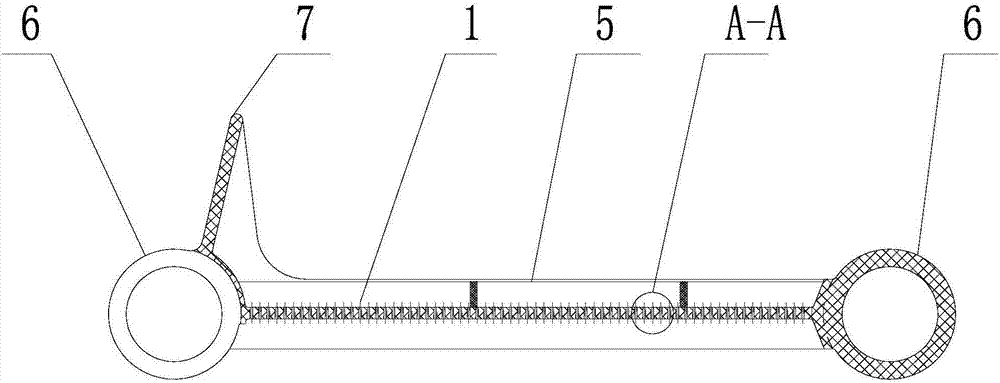

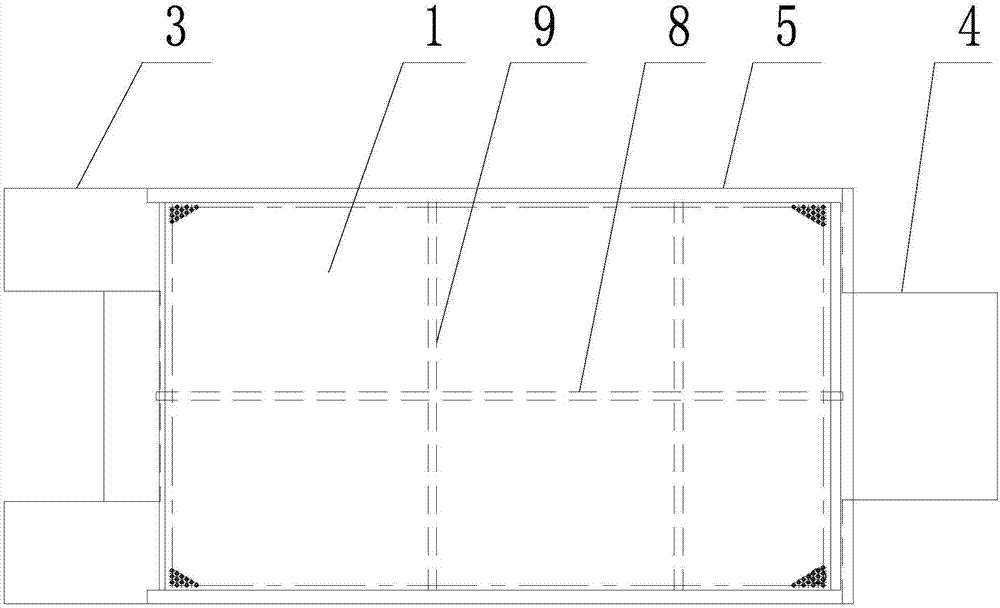

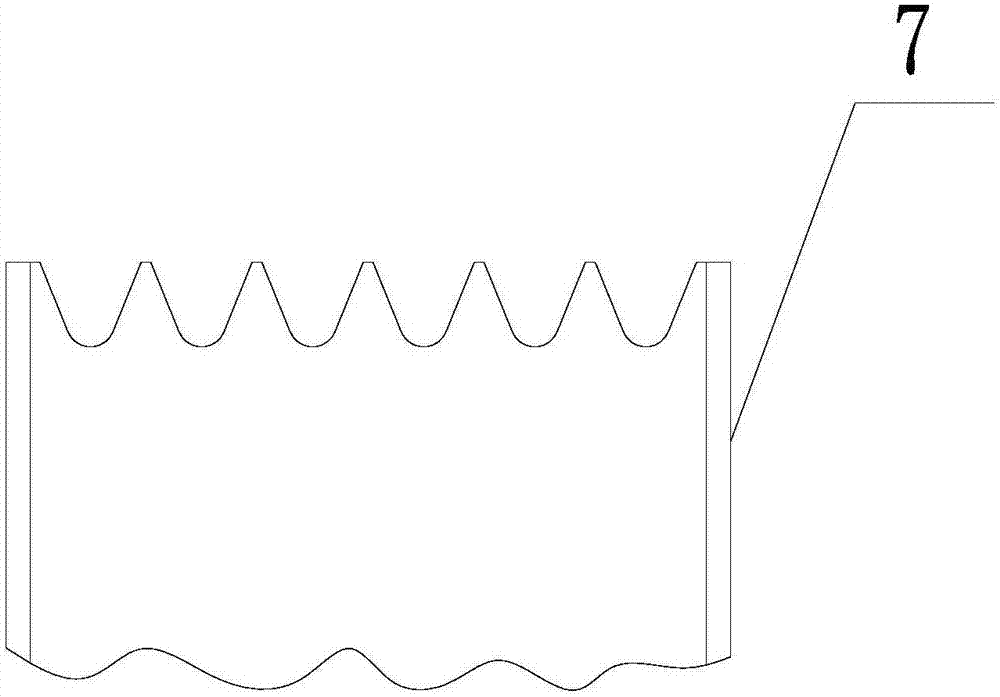

[0030] Attached below Figure 1-4 The inflow grille for sewage treatment, its use method, and sewage treatment equipment of the present invention are described in detail.

[0031] An inflow grill for sewage treatment, the inflow grill includes a non-metallic orifice plate 1 and filter holes 2 arranged on the non-metal orifice plate; wherein, the non-metal orifice plate includes a first The mounting part 3, the second mounting part 4 and the connecting plate part 5 connecting the first mounting part and the second mounting part; the first mounting plate part and the second mounting plate part each include at least one mounting bushing 6, through which The non-metallic orifice plate can be connected into an integral grid part by the shaft rod passing through the installation bushing of the adjacent first mounting plate part in turn, and the connecting shaft rod passing through the installation bushing of the adjacent second mounting plate part in sequence; The filter holes are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com