Reciprocating polishing dust removal device for steel pipes for buildings

A technology for construction and steel pipes, which is applied in the direction of grinding/polishing safety devices, grinding machines, grinding workpiece supports, etc., which can solve the problems of small size of derusting devices, not using pipes for derusting, and increased construction costs, so as to avoid rust The effect of increasing the degree of specialization, increasing the scope of grinding, and improving the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

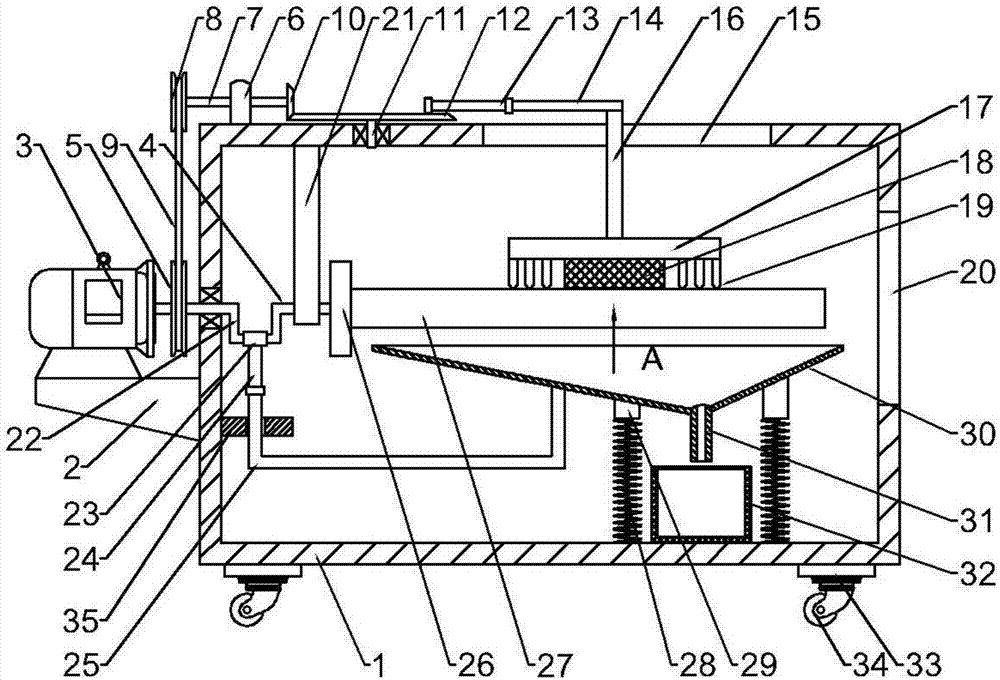

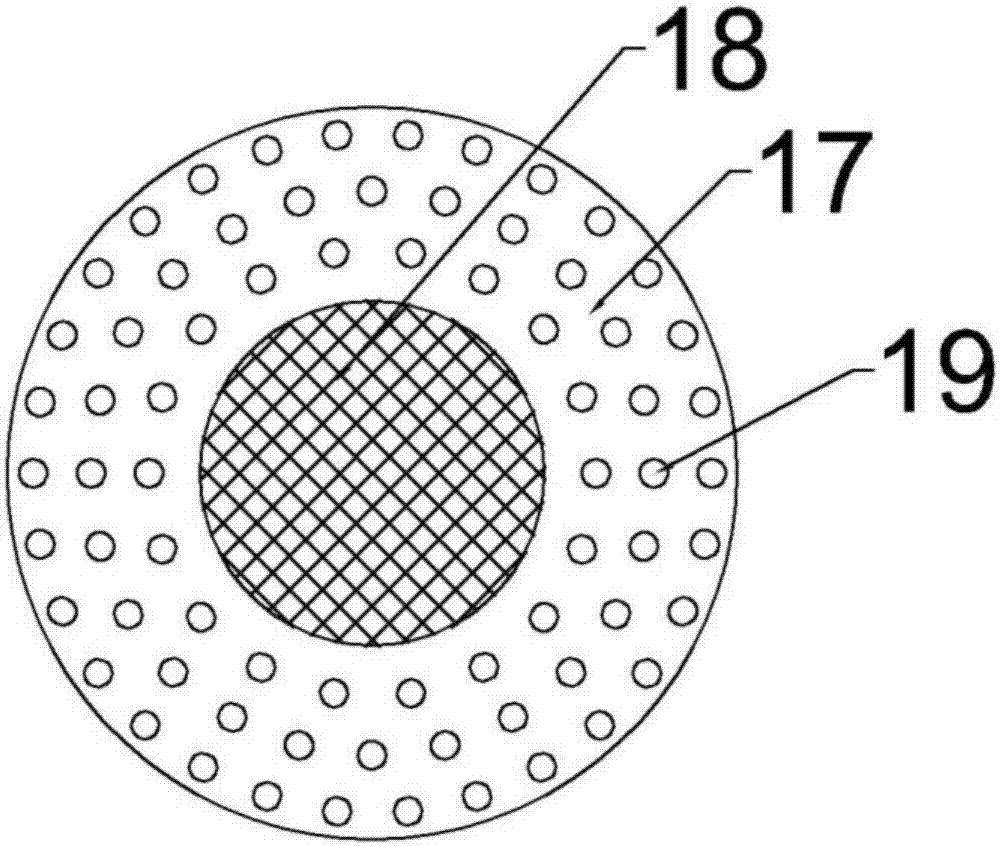

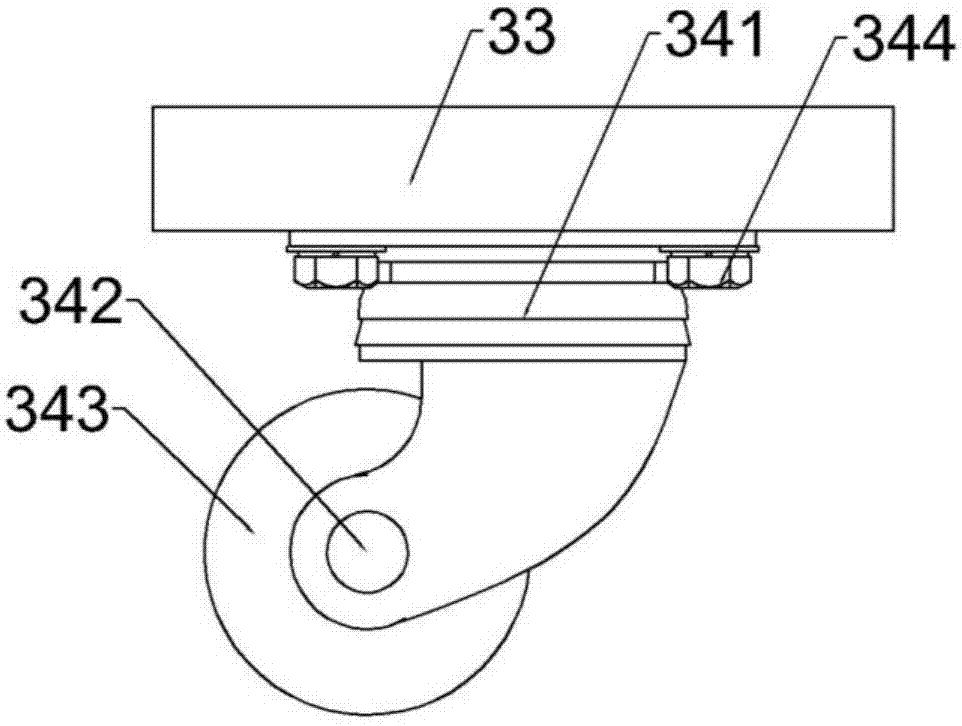

[0022] see Figure 1-4 , a reciprocating grinding and derusting device for steel pipes for construction, comprising a frame 1, a motor base 2 is fixedly connected to the middle part on the left side of the frame 1, a motor 3 is fixedly connected above the motor base 2, and the output end of the motor 3 is fixedly connected to a horizontal The rotating shaft 4 and the horizontal rotating shaft 4 are connected with the frame 1 through bearings, the output end of the motor 3 is fixedly connected with a driving pulley 5, the left side of the top of the frame 1 is fixedly connected with a bearing seat 6, and the inner rotation of the bearing seat 6 is connected with a The gear shaft 7, the left end of the gear shaft 7 is fixedly connected with a driven pulley 8, the drive belt 9 is sleeved between the driven pulley 8 and the driving pulley 5, and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com