Novel absorption package device

A complete set of equipment and a new type of technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of poor use effect, cumbersome manufacturing process, and increase the output power of induced draft fans, etc., to achieve stable operation, spraying Large effect of shower coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

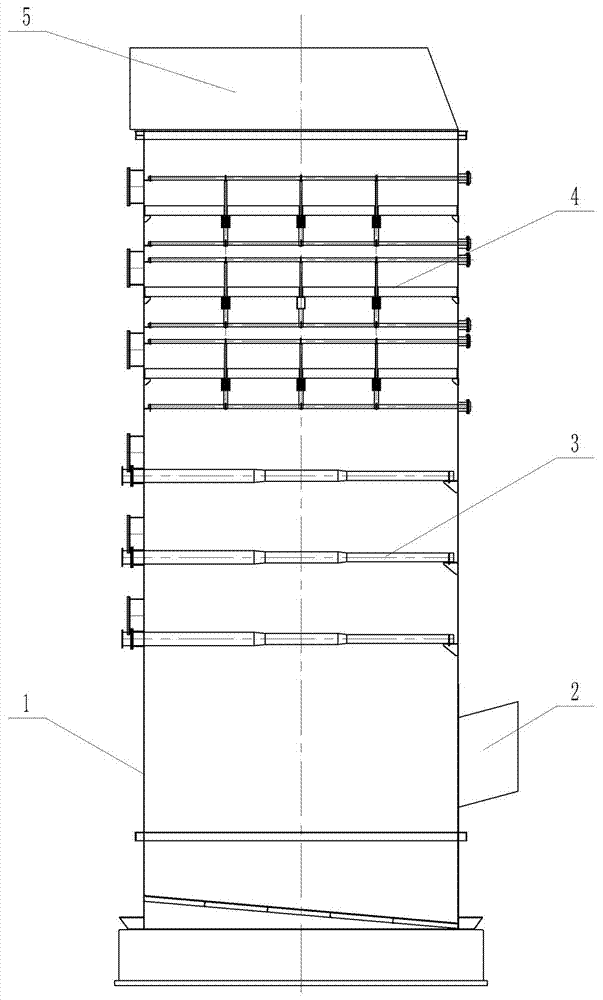

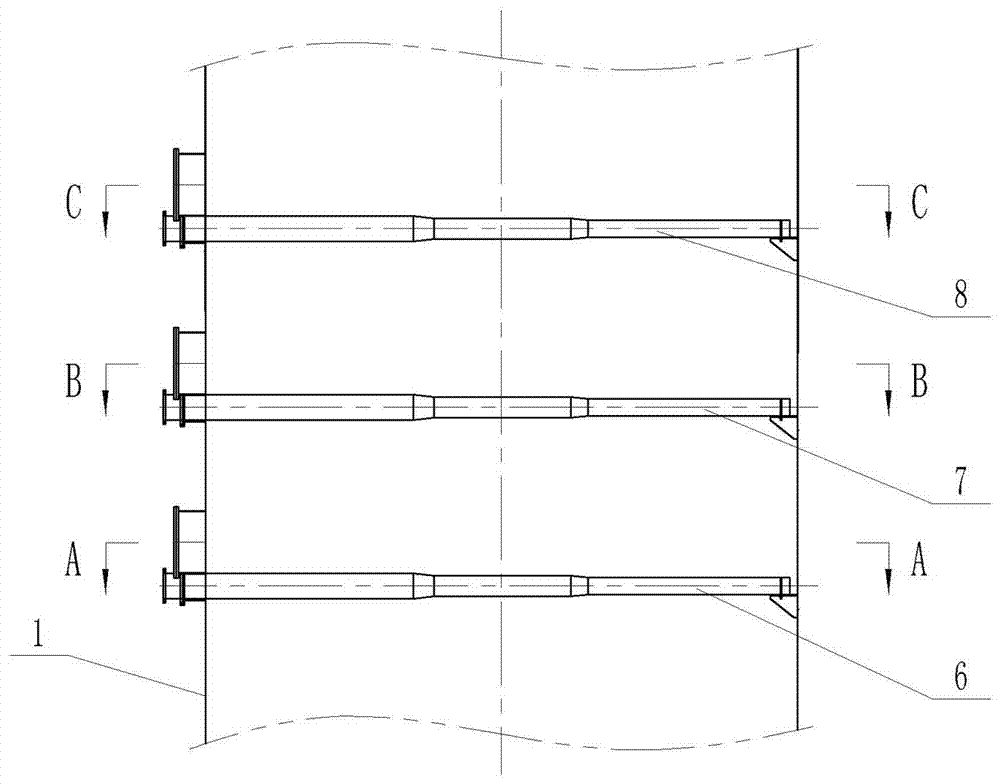

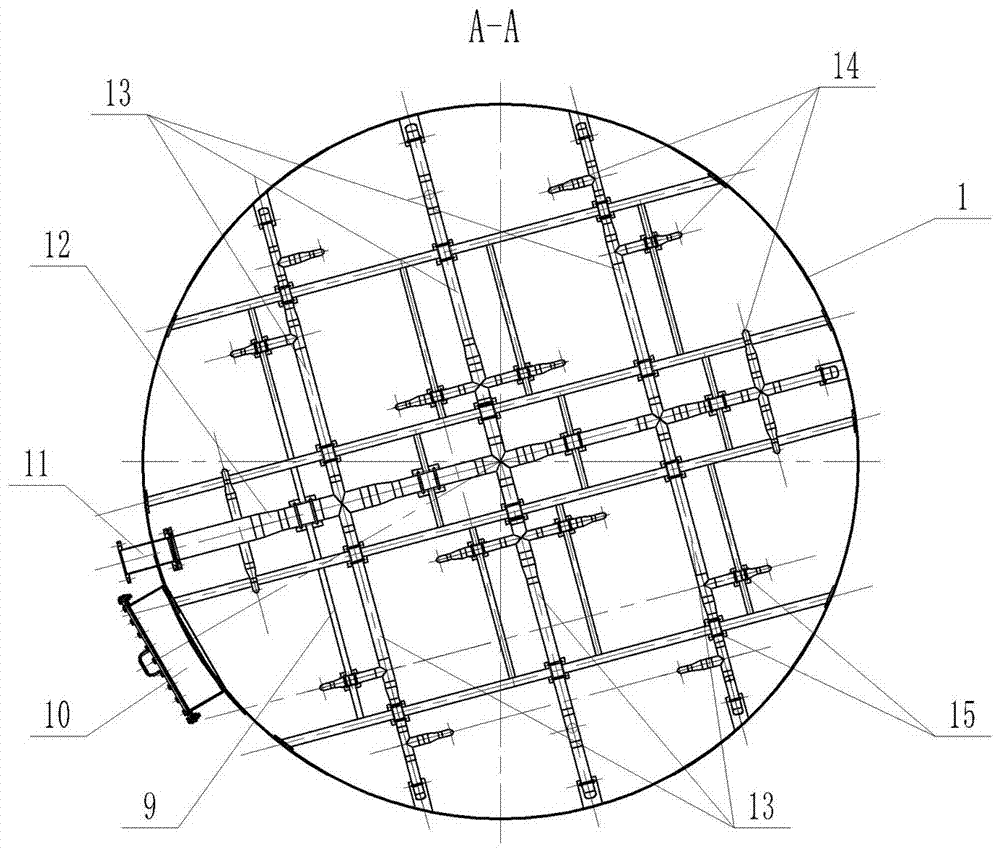

[0036] according to Figure 1-16 The specific structure of the present invention will be described in detail. The new absorption complete set includes a spray device 3 and a dehydration device 4 arranged in the absorption tower main body 1 , wherein the dehydration device 4 is arranged above the spray device 3 . The spray device 3 includes a first spray layer 6, a second spray layer 7 and a third spray layer 8 arranged parallel to each other inside the absorption tower main body 1 along the flow direction of the flue gas; and, the first spray layer arranged in parallel The structure of the spray layer 6, the second spray layer 7 and the third spray layer 8 is the same, and they all include a support frame 9 for supporting the spray pipeline, and a spray main pipe 12 for transporting the spray liquid containing desulfurization agent , and a spray branch pipe 13 for forming a network spray system. The supporting frame 9 of the spraying layer is composed of several supporting m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com