Machine for making fish meat into minced fish

A technology for mashing machine and fish meat, which is applied in the fields of processing fish, slaughtering, food science, etc., can solve the problems of large processing volume of fish meat, high use cost, inconvenience for users, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

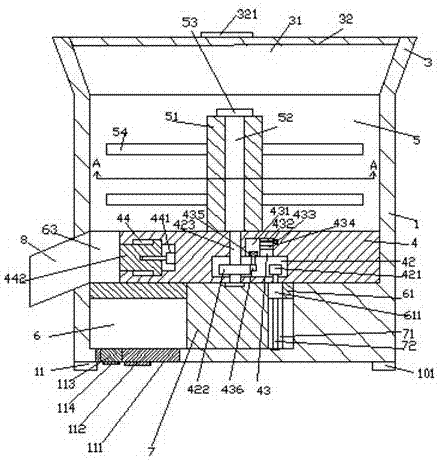

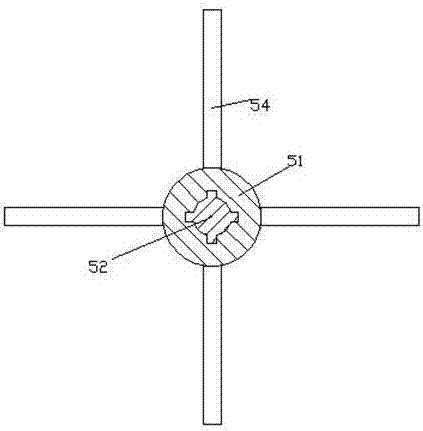

[0029] Such as Figure 1-Figure 9 As shown, a fish minced machine of the present invention includes a cup body 1, the top of the cup body 1 is provided with a feed port 3 with a first accommodating cavity 31, and the top of the feed port 3 is provided with a cover for a cover. Close the cup cover 32 of the first accommodation chamber 31, so as to prevent the fish meat from spraying out of the first accommodation chamber 31 during the cutting process, affecting the cleanliness, and at the same time, it can effectively prevent dust from falling in and increase food safety. The center of the top surface of the cup cover 32 is provided with a pull ring 321, so as to facilitate the covering of the cup cover 32. The cup body 1 is provided with a second accommodation chamber 5, and the second accommodation chamber 5 is left The side bottom wall is provided with a third accommodating chamber 6 communicated with the second accommodating chamber 5 at the top, and the right side of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com