Technical method for grading catalyst in conversion process of catalytic diesel oil

A conversion process and catalytic diesel technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of reducing hydrogenation saturation of gasoline components, strong saturation ability of gasoline components, unfavorable hydrogenation conversion production High-octane gasoline and other problems, to increase the effect of secondary cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

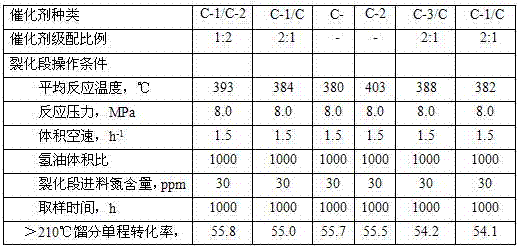

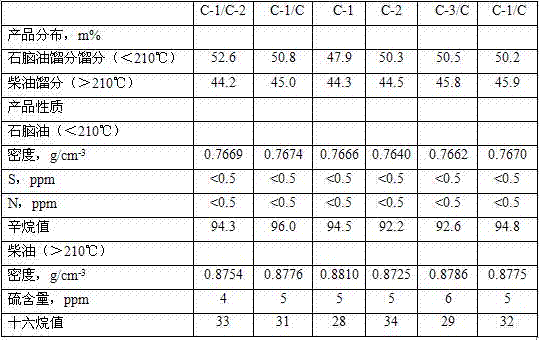

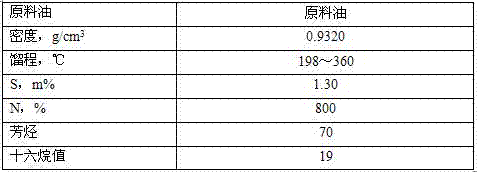

Examples

Embodiment 1

[0029] Preparation method and physical and chemical properties of molecular sieve 1:

[0030] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 1.5mol / L according to the liquid-solid ratio of 4:1, exchange at 80°C for 2 hours, repeat this process twice, and the exchanged Y molecular sieve Na content in Na 2 O is calculated as 2.5%;

[0031] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 560°C and 0.1MPa for 2 hours;

[0032] (3) The molecular sieve obtained in step (2) was stirred and mixed with distilled water according to the liquid-solid ratio of 5:1, and then the temperature was raised to 75°C. During the stirring process, 400ml of 0.6mol / L aluminum sulfate solution was added, and the reaction was carried out at constant temperature for 2 hours.

[0033] (4) First dry the molecular sieve obtained in step (3) at 120°C for 3 hours, then soak the molecular sieve obtained i...

Embodiment 2

[0038] Molecular sieve 2 modification process:

[0039] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 0.6mol / L according to the liquid-solid ratio of 3:1, exchange at 80°C for 3 hours, repeat this process 3 times, and the exchanged Y molecular sieve Na content in Na 2 O is calculated as 2.0%;

[0040] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 530°C and 0.1Mpa for 2 hours;

[0041] (3) Step (2) sieve the oxalic acid solution (concentration in H + Total) 400ml mixed, then heated up to 50°C, and reacted at constant temperature for 2 hours;

[0042] (4) The molecular sieve obtained in step (3) was stirred and mixed with distilled water according to the liquid-solid ratio of 5:1, and then the temperature was raised to 80°C. During the stirring process, 400ml of 0.5mol / L aluminum sulfate solution was added, and the reaction was carried out at constant temperature for 2 ...

Embodiment 3

[0050] Preparation method and physical and chemical properties of molecular sieve 3:

[0051] The Y molecular sieve is modified by conventional methods, that is, the NaY molecular sieve is first ammonium-exchanged to Na 2 The O content is 2.0%, and then mixed with 0.10mol / L ammonium fluorosilicate solution according to the liquid-solid ratio of 10:1 and heated to 80°C, then reacted at a constant temperature for 2 hours. After being treated with ammonium fluorosilicate, the sample was filtered and washed at 0.1 Molecular sieve 3 was obtained by hydrothermal treatment at MPa and 540° C. for 2 h. Molecular sieve 3 has a silicon to aluminum ratio of 15.0. XRD analysis results show that its unit cell constant is 2.442 and its relative crystallinity is 92%. The pore volume is 0.36ml / g, and the infrared acid content determined by infrared analysis is 0.93mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com