Novel nano powder surface treatment method

A nano-powder and surface treatment technology, which is applied in the field of new nano-powder surface treatment and SiO2 nano-powder surface treatment, can solve the problems of high cost and complicated process, and achieve low production cost, reduce the content of impurity ions, and gel The effect of density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

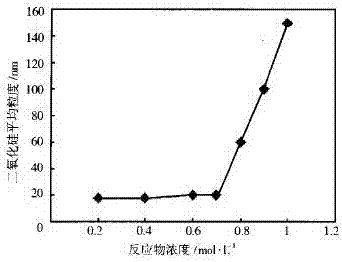

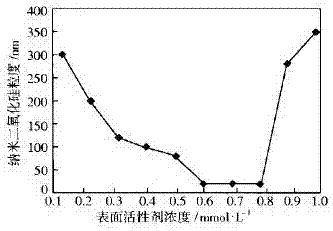

[0014] The present invention is a novel nano-powder surface treatment method. Taking the surface treatment of nano-silica powder material as an example, the micellar method is adopted to use cheap process water glass Na2SiO3 as raw material, such as figure 1 , figure 2 As shown; by adding different types of surfactants into the solution system, the aqueous solution with a certain concentration of 0.6mol / L is prepared according to the ratio of 2:1, and then the acetic acid solution with a certain concentration of 0.6mmol / L is added to form micelles , another anionic surfactant is added to the precipitant. The pH value of the precipitant system is in the range of 8.0~9.0 to form micelles, and the stirring device is fully stirred for 2 hours to make the Na2SiO3 micelle solution and the precipitant micelle solution undergo precipitation reaction, and the stirring speed is 250~4O0r / min , the reaction temperature is controlled at 50-55°C. Under the microenvironment where the preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com