Automobile brake air inlet pipe heating forging detection device

A detection device and automobile braking technology, which is applied in measuring devices, manufacturing tools, and testing the strength of materials by applying stable tension/pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

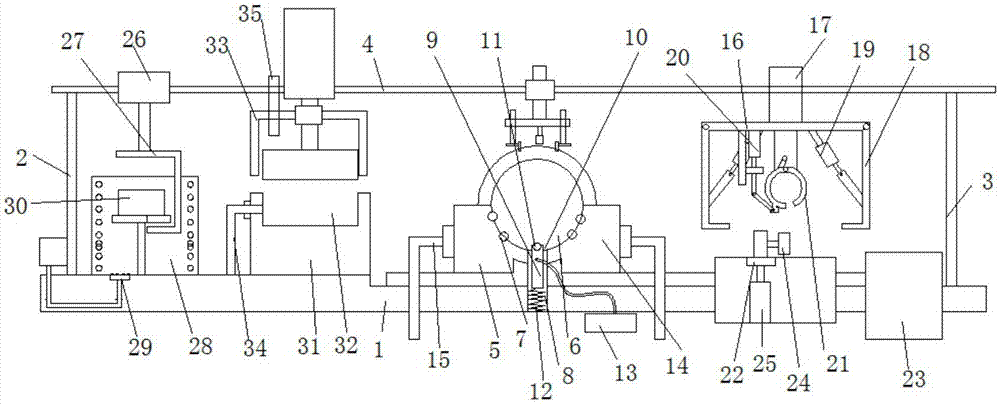

[0011] Referring to the accompanying drawings, an automobile brake air intake pipe heating and forging detection device includes a base 1, and the base 1 is provided with left and right support columns 2, 3, and the tops of the left and right support columns 2, 3 are A beam plate 4 is fixedly installed, a slider 26 is arranged on the beam plate, a cylinder is arranged on the slider 26, the lower end of the cylinder is connected to a carrier 27, and a heating cylinder 28 is arranged below the carrier 27 , a heating wire is arranged on the side wall of the heating cylinder 28, a protective gas nozzle 29 is arranged at the bottom of the heating cylinder 28, a workpiece support 30 is arranged in the heating cylinder 28, and a part of the heating cylinder 28 is provided. The air pressure detection table 31 is provided on the side, the center of the air pressure detection table 31 is provided with a cavity 32, a sealing cover 33 is arranged above the cavity 32, and a cooling jet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com