A demining robot

A technology of robots and hinged supports, applied in offensive equipment, defense devices, etc., can solve problems such as physical threats to soldiers and civilians, incomplete removal of landmine engineers, and civilian injuries caused by landmines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

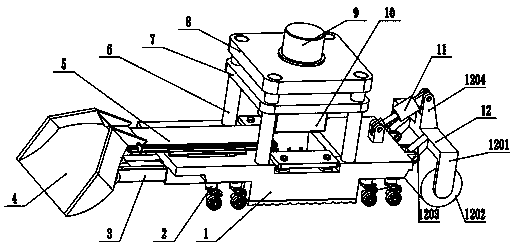

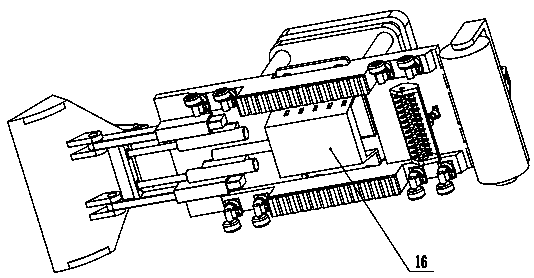

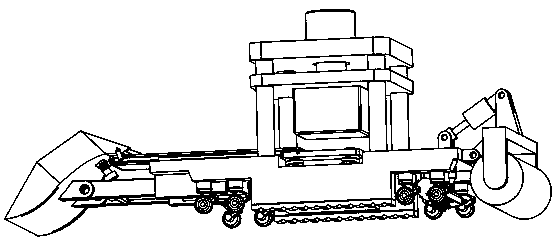

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16As shown, a demining robot includes a chassis module 1, eight walking modules 2, a main arm mechanism 3, a bucket module 4, a transmission module 5, four columns 6, a sliding platform 7, an upper support 8, a first hydraulic pressure Cylinder 9, briquetting block 10, second hydraulic cylinder 11, pressure road module 12, third hydraulic cylinder 13, crushing module 14, four coil springs 15, crushing module 16, fourth hydraulic cylinder 17, two connecting rods 18 , it is characterized in that: the eight walking modules 2 are fixedly installed on the left and right sides of the lower end surface of the vehicle frame 101 of the chassis module 1 through their respective fixing seats 201; the two slide rails 301 of the main arm mechanism 3 are respectively slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com