Non-woven embroidery backing paper and its preparation method

A technology of interlining and weight, applied in the field of non-woven embroidery interlining and its preparation, can solve the problem of low basis weight of finished paper, and achieve the effects of low basis weight, high strength and high longitudinal and transverse tensile strength of interlining paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

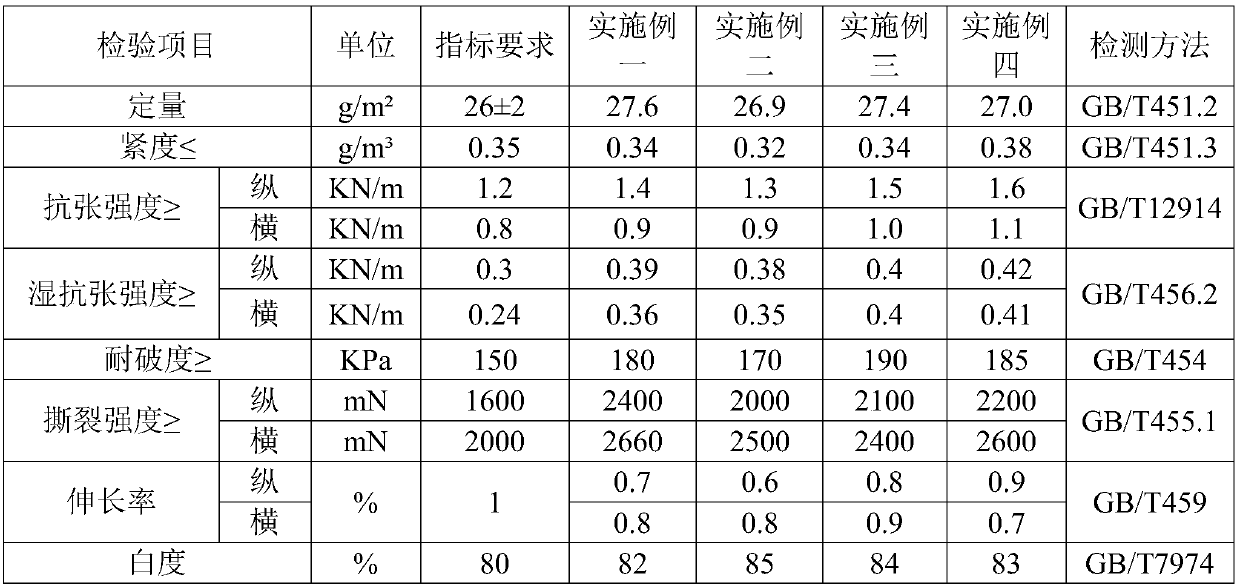

Examples

Embodiment 1

[0032] Non-woven embroidery interlining paper and preparation method thereof:

[0033] (1) The ratio of raw materials: softwood pulp accounts for 35% of the drying weight of the non-woven embroidery interlining paper, rayon fiber accounts for 35% of the dry weight of the non-woven embroidery interlining paper, and polyester fiber accounts for the non-woven embroidery interlining paper. 18% of the dry weight, the sizing agent accounts for 12% of the drying weight of the non-woven embroidery interlining paper, wherein the fineness of the rayon fiber is 1.5D, the length is 8-10mm, and the fineness of the polyester fiber is 1.5D, The length is 14-16mm, and the weight percentage of each component in the sizing agent aqueous solution is 7% of polyvinyl alcohol and 5% of styrene-butadiene rubber.

[0034] (2) Beating: Add softwood pulp, rayon fiber and water to the hydraulic pulper, the slurry concentration is 5%, beating, and the beating current is 80 amperes, so that the pulp beati...

Embodiment 2

[0042] Non-woven embroidery interlining paper and preparation method thereof:

[0043] (1) The ratio of raw materials: softwood pulp accounts for 30% of the dry weight of the non-woven embroidery interlining paper, rayon fiber accounts for 40% of the dry weight of the non-woven embroidery interlining paper, and polypropylene fiber accounts for the non-woven embroidery interlining paper. 15% of the dry weight, the sizing agent accounts for 15% of the drying weight of the non-woven embroidery interlining paper, wherein the fineness of the rayon fiber is 1.5D, the length is 6-10mm, the fineness of the polypropylene fiber is 1.5D, The length is 12-14mm, and the weight percentage of each component in the sizing agent aqueous solution is 9% of polyvinyl alcohol and 4% of styrene-butadiene rubber.

[0044] (2) Beating: add softwood pulp, rayon fiber and water in the hydraulic pulper, the slurry concentration is 6%, beating, the beating current is 90 amperes, the pulp beating degree i...

Embodiment 3

[0052] Non-woven embroidery interlining paper and preparation method thereof:

[0053] (1) The ratio of raw materials: softwood pulp accounts for 38% of the dry weight of the non-woven embroidery interlining paper, rayon fiber accounts for 32% of the dry weight of the non-woven embroidery interlining paper, and polyethylene fiber accounts for the non-woven embroidery interlining paper. 17% of the dry weight, the sizing agent accounts for 13% of the drying weight of the non-woven embroidery interlining paper, wherein the fineness of the rayon fiber is 1.5D, the length is 10-12mm, the fineness of the polyethylene fiber is 1.5D, The length is 16-18mm, and the weight percentage of each component in the sizing agent aqueous solution is 10% of polyvinyl alcohol and 6% of styrene-butadiene rubber.

[0054] (2) Beating: Add softwood pulp, rayon fiber and water to the hydraulic pulper, the slurry concentration is 5%, beating, the beating current is 100 amperes, the pulp beating degree is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com