Veterinary D-type clostridium perfringen toxin, and preparation method and special culture medium of D-type clostridium perfringen toxin

A technology of Clostridium perfringens and toxin-producing medium, which is applied in biochemical equipment and methods, veterinary vaccines, chemical instruments and methods, etc., and can solve the problems of unstable toxin-producing performance, waste of vaccine production, and high cost To achieve the effects of stable toxin-producing performance, convenient preparation and use, and strong toxin-producing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

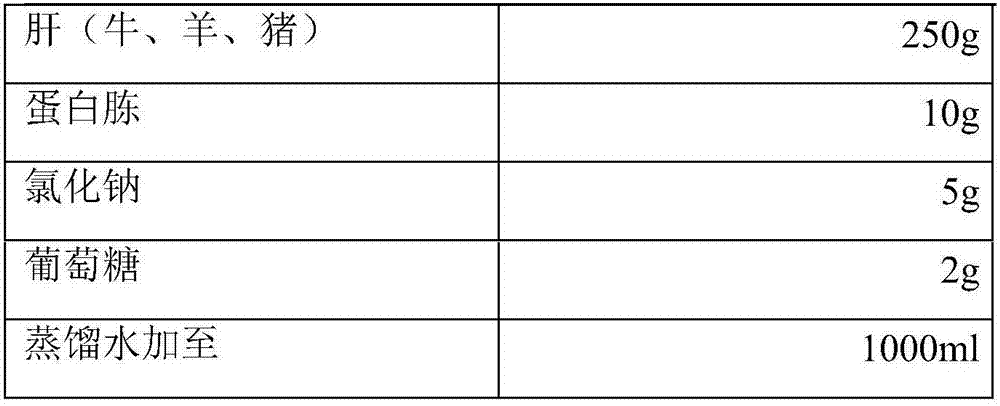

[0047] Embodiment 1, the screening of Type D Clostridium perfringens toxin-producing medium

[0048] (1) Three different medium formulations were designed:

[0049] Formula 1: Soybean peptone 15g, casein peptone 15g, yeast extract powder 5g, glucose 5g, purified water to 1000mL.

[0050] Formula 2: Show peptone 10g, casein peptone 10g, yeast extract powder 15g, sodium chloride 4g, sodium carbonate 0.6g, calcium chloride 0.1g, cystine 2g, glucose 10g, add purified water to 1000mL.

[0051] Formula 3: Soybean peptone 10g, casein peptone 10g, yeast extract powder 5g, Na 2 HPO 4 12H 2 O 5g, dextrin 10g, purified water added to 1000mL.

[0052] (2) Prepare culture medium

[0053] Except for dextrin and glucose, weigh or measure each component according to the above content, add purified water, heat to fully dissolve, add purified water to make it to the final volume required for preparation, adjust with 10M sodium hydroxide pH value to 7.5 ~ 8.0. Add dextrin to formula 3 acc...

Embodiment 2

[0066] Embodiment 2, the optimization of the preparation of Clostridium perfringens type D toxin-producing medium and the method of use

[0067] (1) Optimization of Erlenmeyer flask culture conditions

[0068] The culture temperature, initial pH value, and culture time were optimized by means of static culture in the triangular flask, and the optimal conditions were determined to be "the initial pH value of the medium was 8.0-8.5, and cultured at 35-37°C for 17-18 hours".

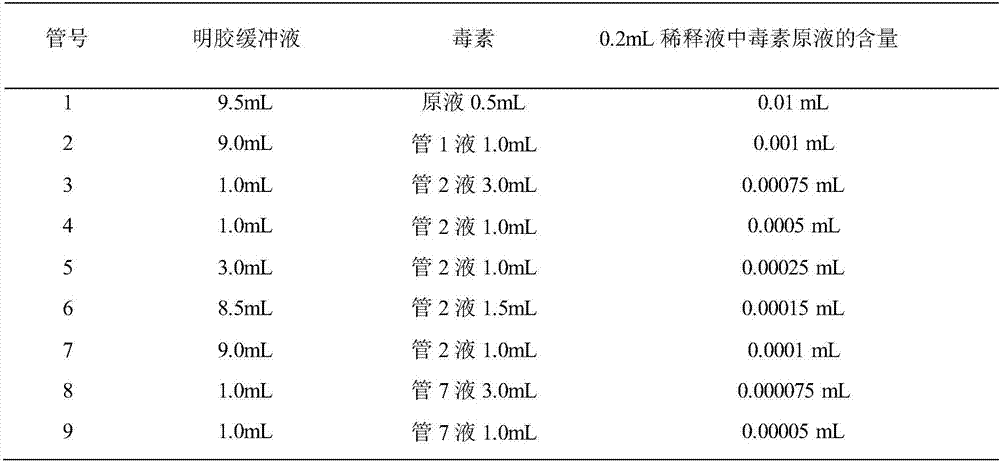

[0069] The virulence result table of Erlenmeyer flask culture with optimized conditions

[0070]

[0071]

[0072] As can be seen from the above table, according to the method of the present invention, the highest virulence can be raised to 10 times of the seedling production standard of the regulations.

[0073] (2) Optimization of fermentation tank culture conditions

[0074] The control of pH value, culture time, and sugar supplementation were optimized by means of fermentation tank culture, and ...

Embodiment 3

[0078] Example 3, Preparation and Efficacy Evaluation of Type D Clostridium perfringens Toxoid Vaccine

[0079] Take the cultured bacterial culture, add 0.7% formaldehyde solution (40%) by volume, and put it at 35°C for inactivation and detoxification for 5 days. Take the inactivated and detoxified bacteria solution to inoculate anaerobic broth, common broth, and common agar slant, and observe the sterile growth for 5 days, indicating that the inactivation is complete; at the same time, the inactivated and detoxified bacteria solution is centrifuged at 3000r / min for 30min, and the bacteria are discarded Keep the supernatant from the precipitate, filter the supernatant with a 0.22 μm filter membrane, inject 2 mice with a weight of 16-18 g into the tail vein, and inject 0.4 ml into each mouse, and observe the health and life for 3 days, indicating that the detoxification is complete.

[0080] Take the inactivated and detoxified bacterial solution, centrifuge at 3000r / min for 30m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com