Driving working platform of sand shooting machine

A technology of workbench and sand shooting machine, which is applied in the direction of molding table, molding machine, manufacturing tools, etc., which can solve the problems of low production efficiency and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

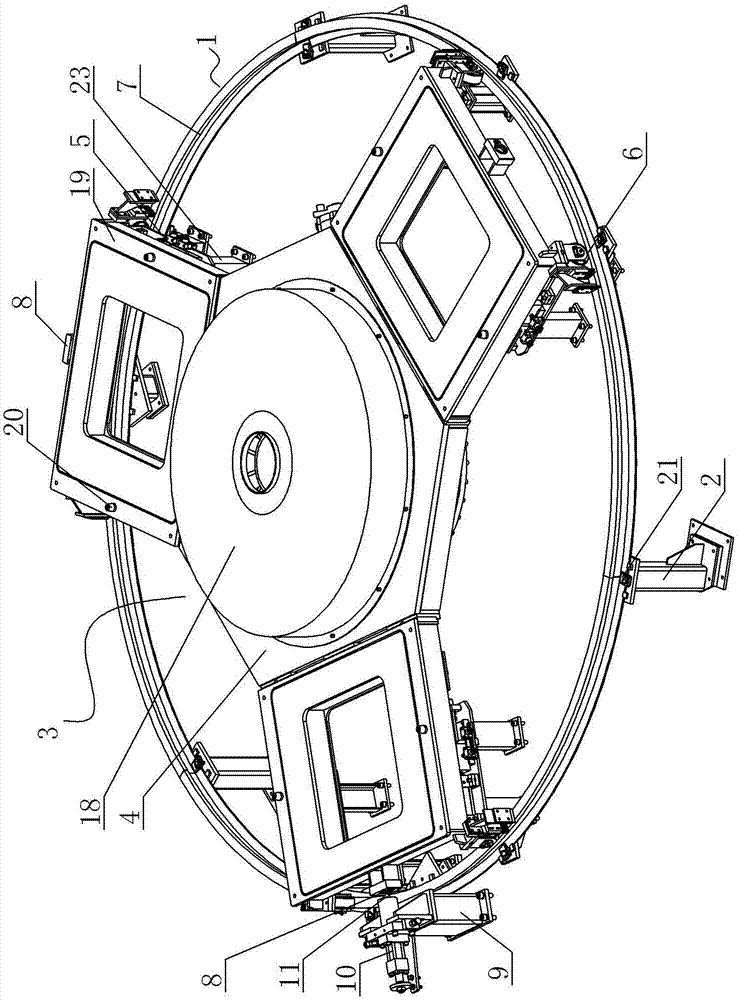

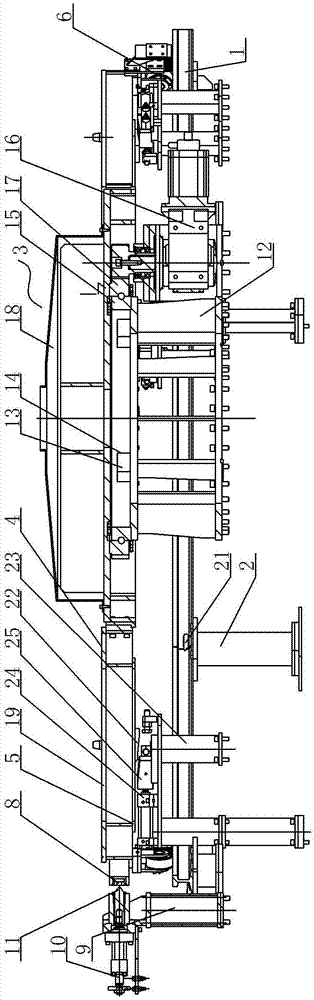

[0017] A driving workbench of a sand blasting machine, see figure 1 , figure 2 : It includes a closed circular track 1, the lower end surface of the circular track 1 is supported by several support frames 2, the center of the circular track 1 is arranged with a turntable 3, and the output outer ring surface 4 of the turntable 3 is evenly distributed with three side convex Support platform 5, the outer lower end surface of each support platform 5 is provided with at least one guide wheel 6, the bottom of guide wheel 6 is supported in the concave track 7 of the upper end surface of circular track 1, and the outer side of each support platform 5 is provided with a pair of In the locking hole 8, a rotary positioning seat 9 is arranged on the outer side of the annular track 1 corresponding to the position of one of the stations. The rotary positioning seat 9 is provided with a radial positioning oil cylinder 10, and the output end of the radial positioning oil cylinder 10 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com