Sulfur hexafluoride automatic recycling device

An automatic recovery, sulfur hexafluoride technology, applied in the field of SF6 application, can solve problems such as leakage, gas pollution and compression, and achieve the effects of fast maintenance, cost reduction, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

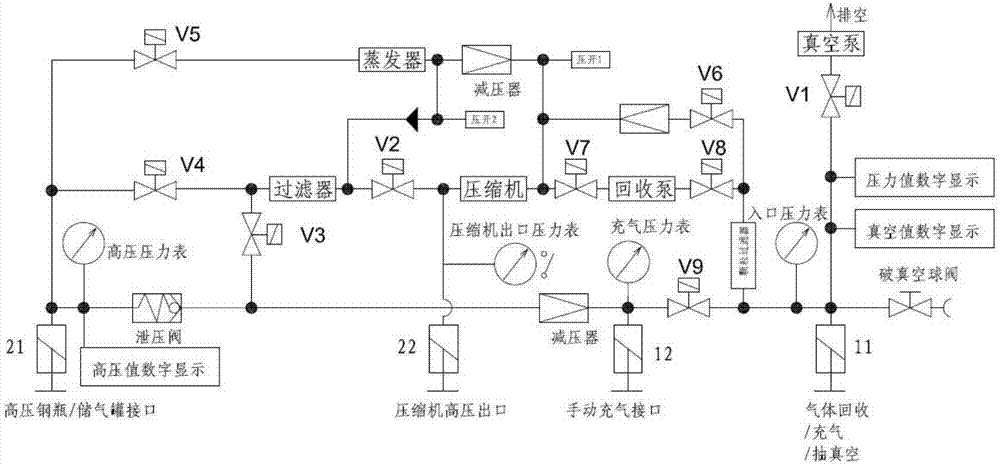

[0064] An automatic sulfur hexafluoride recovery and treatment device, including a gas storage device installed on a support device, a filtration system, a compression system, a pipeline system, and an electrical control system; wherein, the filtration system includes a particle filter and a moisture filter; The compression system includes compressors and recovery pumps; the pipeline system includes the pipelines connecting various devices and the electromagnetic control valves on the pipelines; the electrical control system includes sensors, electrical control components, and instrument display devices; the connection relationship and work of each component principle such as figure 1 shown. The compression device adopts oil-free lubrication, and there is no lubricating oil.

[0065] The gas storage device is a storage tank or a gas cylinder, which stores the recovered gas in liquid state after particle filtration, water filtration and decomposition product filtration. The g...

Embodiment 2

[0080] Such as figure 1 As shown, an automatic sulfur hexafluoride recovery treatment device includes the following components: support frame, compressor, recovery pump, vacuum pump, vacuum power source coaxial valve, external heat evaporator, gas storage tank, dust filter, dry Type filter, multiple solenoid valves and pipelines connecting various components, touch screen and PLC and other electronic control components. The structure and function of each component are the same as in Embodiment 1. The sulfur hexafluoride automatic recycling and processing device includes an automatic vacuuming system, an air charging system, and a recovery and compression system.

[0081] For vacuum systems, refer to figure 1 , its working principle and working route are: before operation, please connect the pipe with self-sealing joint to port 11 of the equipment, and connect the other end to the equipment that needs to be vacuumed. Start automatic vacuuming by touching the screen, set the ...

Embodiment 3

[0095] An automatic sulfur hexafluoride recovery and treatment device, including the following components: a support frame, a compressor, a recovery pump, a vacuum pump, a vacuum power source coaxial valve, an external heat evaporator, an air storage tank, a dust filter, and a dry filter , multiple solenoid valves and pipelines connecting various components, touch screen and PLC and other electronic control components. The structure and function of each component are the same as in Embodiment 1. The sulfur hexafluoride automatic recycling and processing device includes an automatic vacuuming system, an air charging system, and a recovery and compression system.

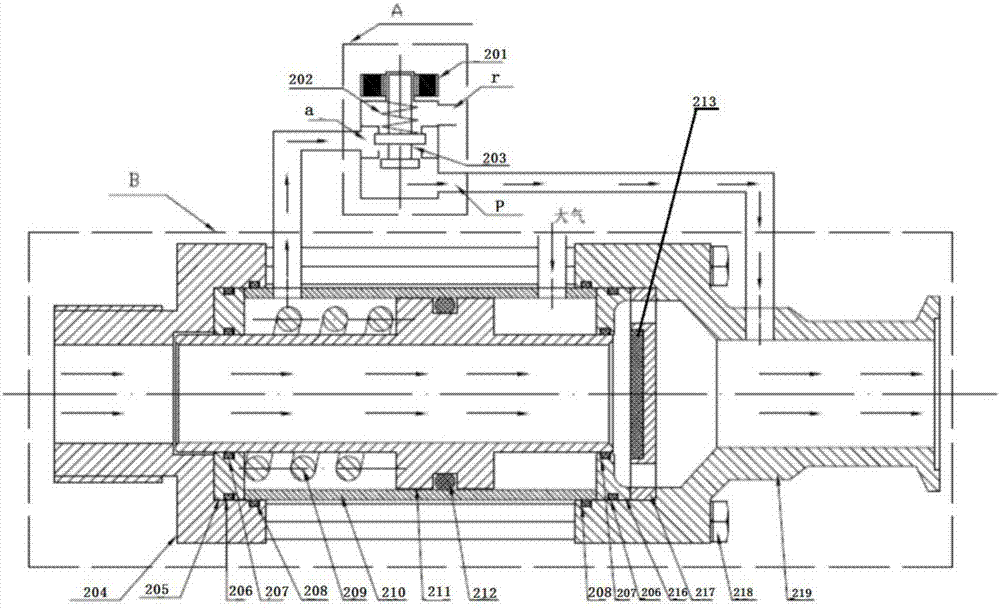

[0096] In the technical solution of this embodiment, the vacuum pumping system is equipped with a coaxial valve with vacuum as the power source in front of the vacuum pump inlet, which is used to protect the vacuum pump from positive pressure, and at the same time as an isolation control between the vacuum pump and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com