Large-inclined-angle coal cutter dragging control device and control method

A technology of shearer and large inclination angle, which is applied to earth-moving drilling, cutting machinery and other directions, can solve the problems of low work efficiency, overload of traction unit, no other measures to ensure, etc., and achieves simple structure, reasonable design, realization and use. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

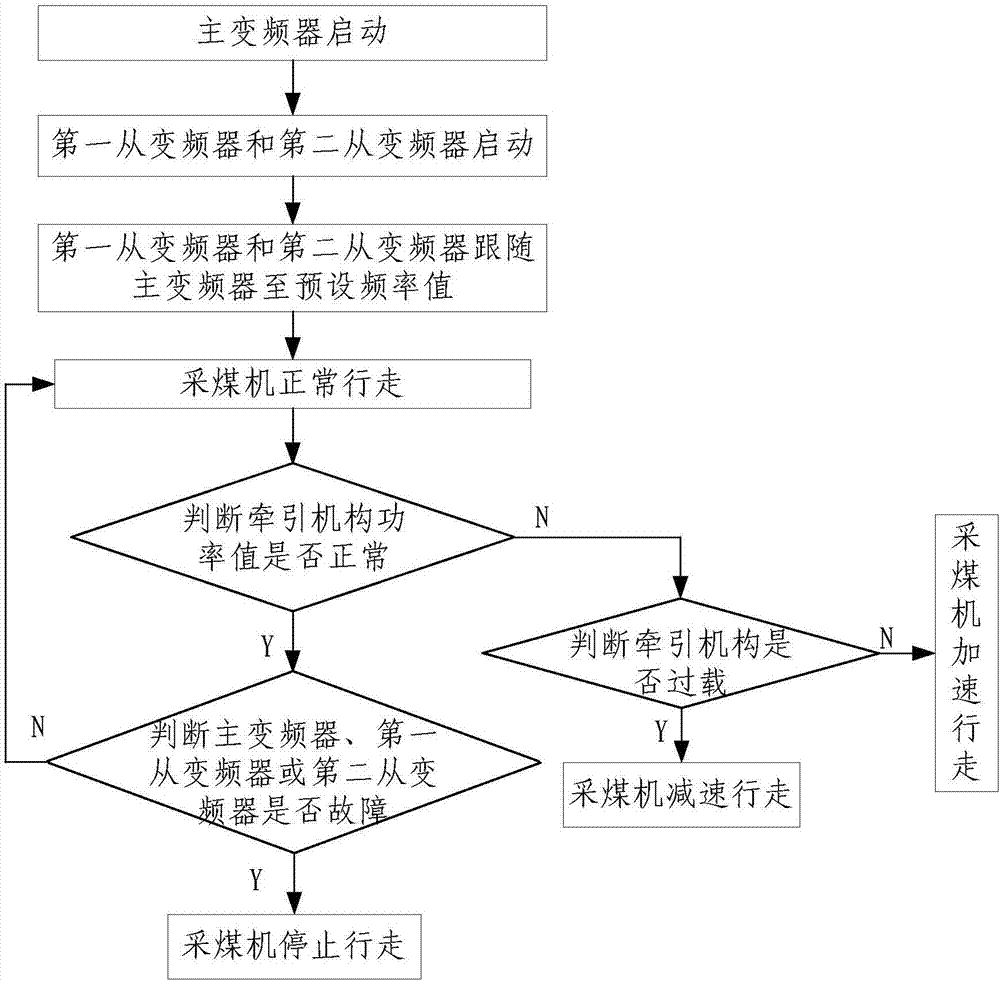

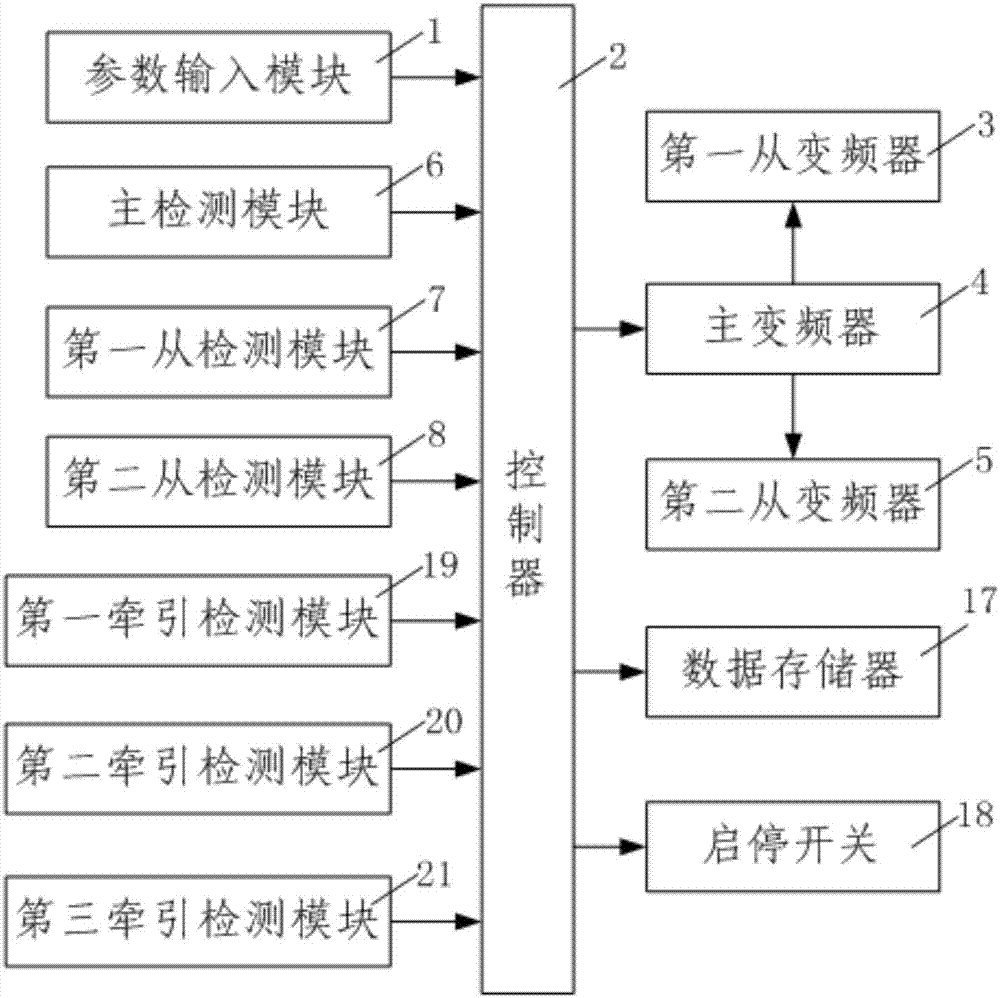

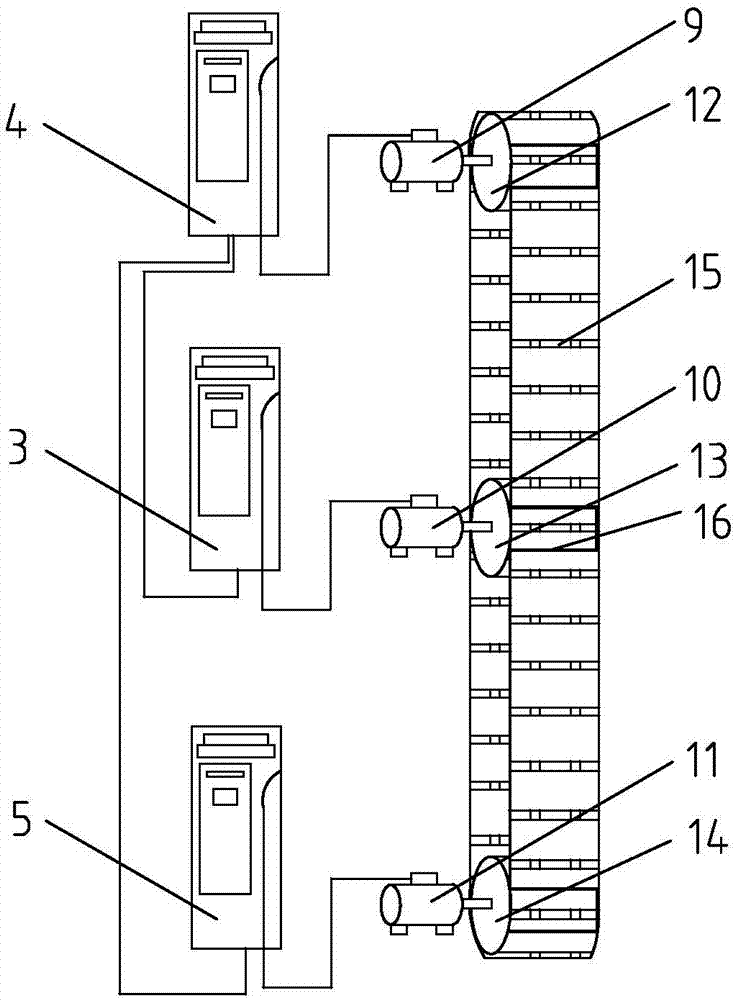

[0041] Such as figure 2 and image 3 As shown, the present invention includes a traveling mechanism, a traction mechanism for driving the traveling mechanism and an electrical control mechanism for controlling the traction mechanism, and the traveling mechanism includes a first traveling unit 12, a second traveling unit 13 and a third traveling unit 14 , the first traveling unit 12, the second traveling unit 13 and the third traveling unit 14 all include a gear rail 16 engaged with the pin rail 15 of the scraper conveyor on the working surface with a large inclination angle, and the traction mechanism includes a gear rail 16 for pulling the first The first traction motor 9 of a travel unit 12, the second traction motor 10 for traction of the second travel unit 13 and the third traction motor 11 for traction of the third travel unit 14, the electrical control mechanism includes a controller 2 and the parameter input module 1 connected to the input terminal of the controller 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com