Self-resetting swing reinforced concrete column based on shape memory alloy

A technology of reinforced concrete columns and memory alloys, which is applied in basic structural engineering, building components, earthquake resistance, etc., can solve problems such as complex structure and troublesome assembly, and achieve the effects of convenient construction, flexible design and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

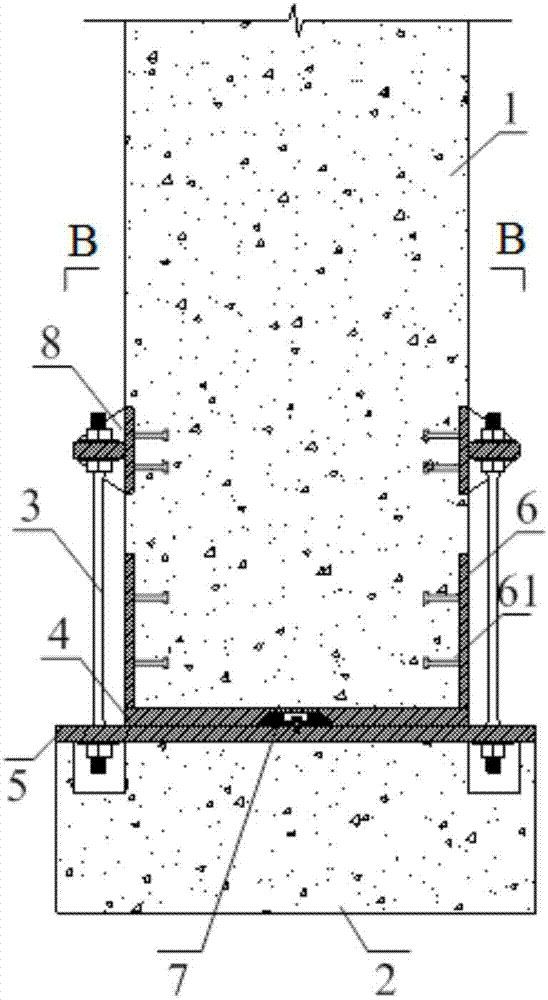

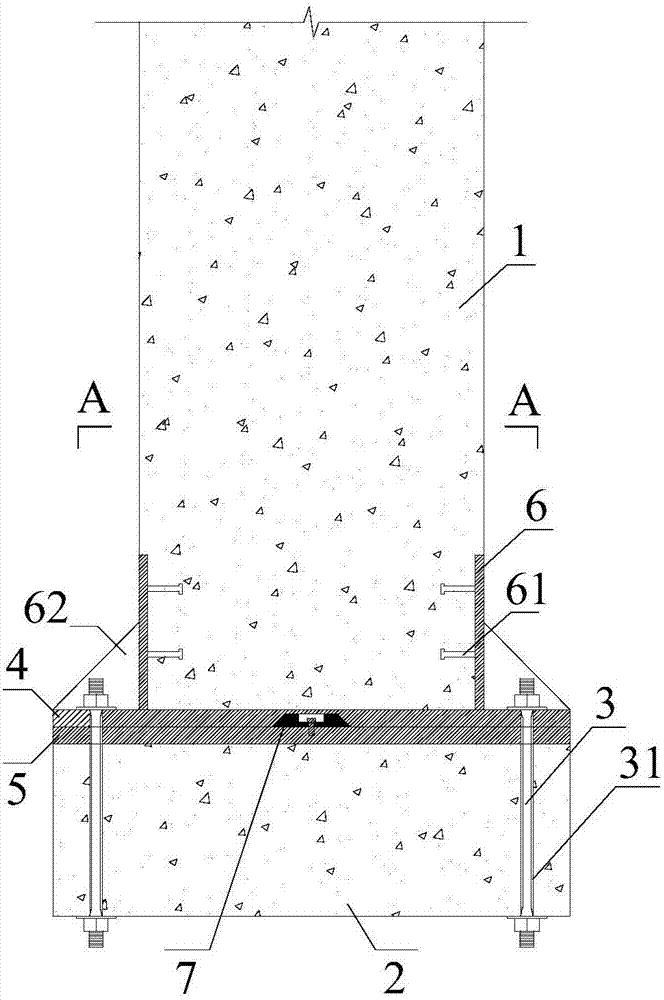

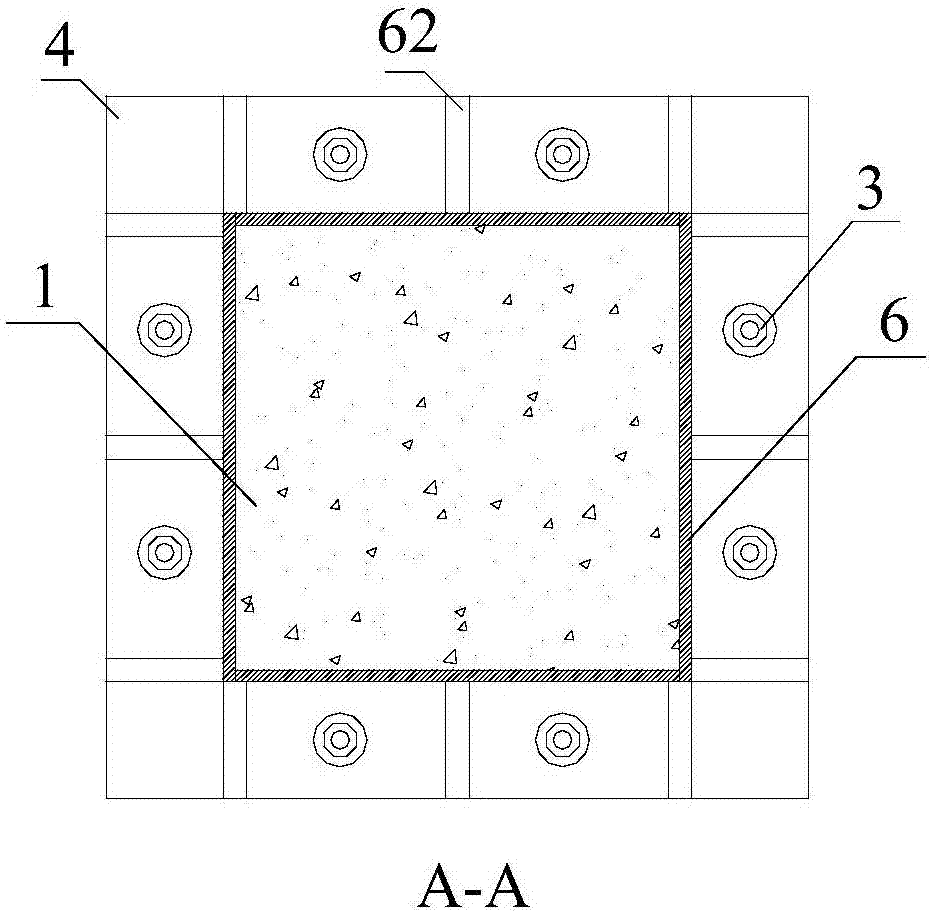

[0044] A self-resetting swaying reinforced concrete column based on a superelastic shape memory alloy, the structure of which is as follows figure 1 and figure 2 As shown, it includes a prefabricated reinforced concrete column 1 , a superelastic shape memory alloy screw 3 , a shear element 7 and a concrete foundation 2 . In order to reduce the damage to the concrete at the bottom of the prefabricated reinforced concrete column 1 and the top surface of the concrete foundation 2, the steel plate 4 at the bottom of the column and the steel plate 5 at the top of the foundation are pre-embedded on the contact surfaces respectively. At the same time, the steel plate 4 at the bottom of the column is welded to the longitudinal reinforcement in the prefabricated reinforced concrete column 1 at the bottom. The prefabricated reinforced concrete column 1 and the concrete foundation 2 are connected by a superelastic shape memory alloy screw 3 , and a shear element 7 is arranged between t...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 lies in the arrangement of the superelastic shape memory alloy screw 3 .

[0050] Specifically, similar to Example 1, such as Figure 8 and Figure 9 As shown, in order to facilitate the installation of the superelastic shape memory alloy screw 3, the superelastic shape memory alloy screw 3 is arranged on the periphery of the prefabricated reinforced concrete column 1 by pre-embedding the steel connector 8 on the prefabricated reinforced concrete column 1 . The upper end of the superelastic shape memory alloy screw 3 is fixed on the steel connector 8, while the lower end is anchored on the bottom of the foundation top steel plate 5, and a deformation space is reserved for the superelastic shape memory alloy screw 3 in the concrete foundation 2. The superelastic shape memory alloy screw 3 is only subjected to tension and not to compression during the entire repeated loading process.

[0051] A shear element 7 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com