Preparation method of tauroursodeoxycholic acid

A technology of tauroursodeoxycholic acid and conversion method, which is applied in the field of preparation of tauroursodeoxycholic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Whole-gene synthesis of codon-optimized 7α-HSDH and 7β-HSDH genes

[0065] 7α-HSDH and 7β-HSDH are 7α-hydroxysteroid dehydrogenase and 7β-hydroxysteroid dehydrogenase, respectively;

[0066] The two 7α-HSDHs were derived from: Clostridium sardiniense strain DSM599, GenBank accession number: JN191345.1) and Escherichia coli strain TW14359, GenBank accession number: CU928163.2),

[0067] Two 7β-HSDH genes were derived from: Clostridium sardiniense strain DSM599, GenBank accession number: JN191345.1) and Ruminococcus gnavus strain N53, GenBank accession number: KF052988.1),

[0068] The above sequence was entrusted to Yingwei Jieji (Shanghai) Trading Co., Ltd. to use GeneArt software to optimize the codon of the gene sequence according to the codon preference of Escherichia coli, and to carry out the whole gene synthesis, which are respectively recorded as α1, α2, β1, and β2.

[0069] The codon-optimized 7α-HSDH derived from Clostridium sardiniense (denoted as α 1 ) gene...

Embodiment 2

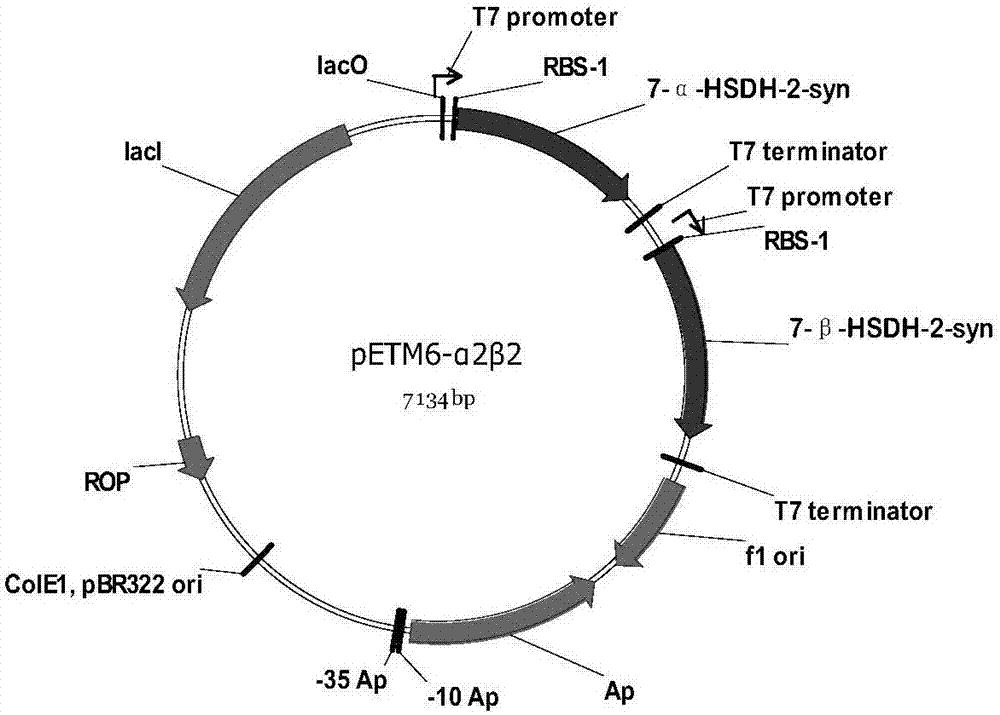

[0071] Construction of engineered bacteria

[0072] 1) Expanded culture using pMD as a carrier with a synthetic target gene α 1 、α 2 , β 1 , β 2 coli, and DH5α-pETM6 strain, take 10μl sample, add 10ml of LB (Amp + ) medium, cultivated on a shaker at 37° C. for 12 to 16 hours, and the shaker speed was 225 rpm.

[0073] 2) Use the plasmid extraction kit purchased from Shanghai Chuangying Biotechnology Co., Ltd. to extract the plasmids of the above bacteria, and operate according to the operation instructions of the kit.

[0074] 3) pMD-α obtained by double enzyme digestion and extraction 1 , pMD-α 2 , pMD-β 1 , pMD-β 2 Plasmid, and expression vector pETM6, the enzyme digestion system is as follows:

[0075]

[0076] Digest at 37°C for 2 to 4 hours, and purify the target fragment with a gel recovery kit.

[0077] 4) The recovered 850bp target gene fragment α 1 、α 2 , β 1 , β 2 , respectively, and the 5.6kb pETM6 carrier fragment, the connection system is as follo...

Embodiment 3

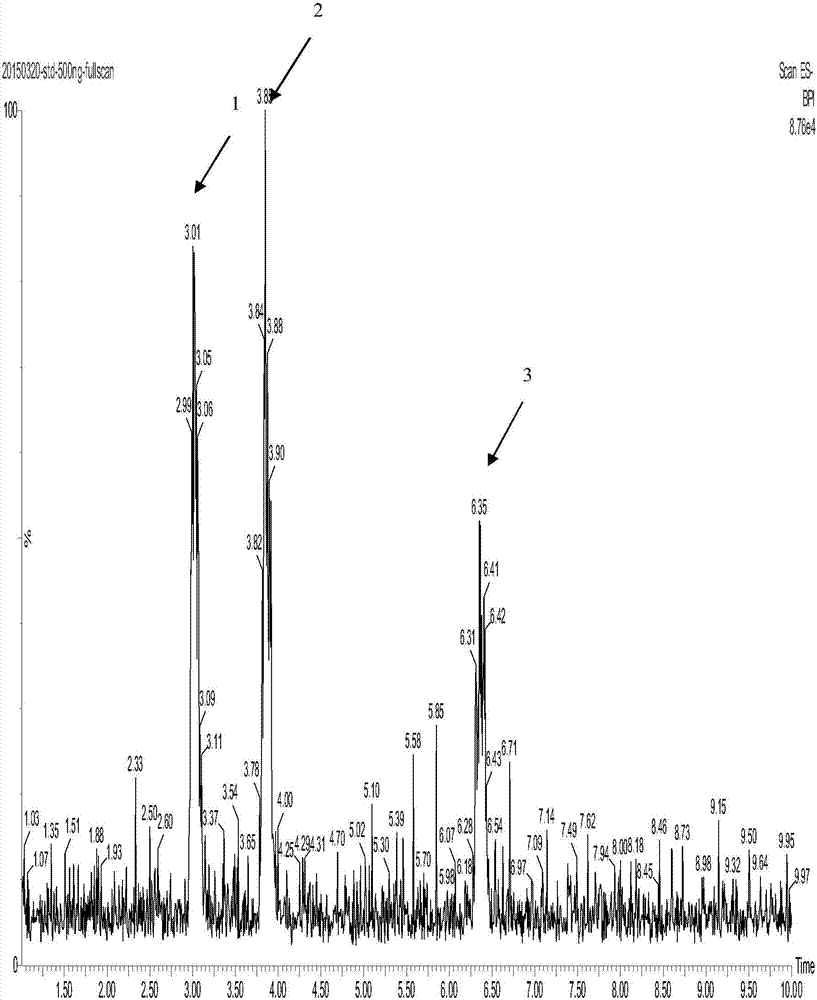

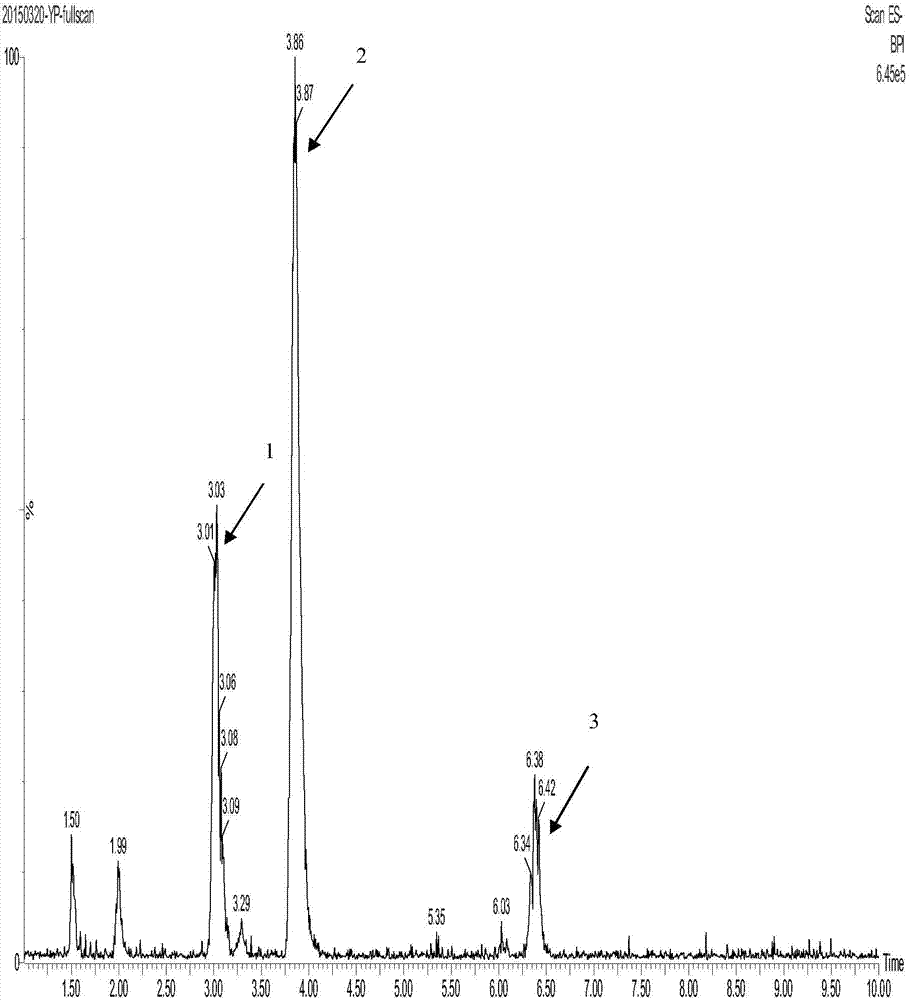

[0101] Cultivation of engineering bacteria and transformation of substrates

[0102] 1) Inoculate the engineered bacteria into LB solid plate medium, activate and cultivate at 37°C for 12 hours;

[0103] 2) Pick a single colony from the LB solid plate medium and inoculate it in LB (Amp + ) liquid culture medium in the Erlenmeyer flask, at 225rpm / min, 37 ℃ shaking culture for 14 hours;

[0104] 3) The above culture was inoculated into liquid M9 medium at a ratio of 1:50, cultured with shaking at 225rpm / min and 37°C for 3.5 hours, and 1mM isopropyl-β-D-thiogalactopyranoside ( IPTG), continue to cultivate for 3 hours;

[0105] 4) Centrifuge the above culture at 5000g / min, collect the bacteria, and concentrate 15 times into a new M9 medium supplemented with 100mg / L Amp+, 1mM IPTG, and 8mM TCDCA. Shake culture at 225 rpm and 37° C. for 2 days to carry out fermentative transformation of the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com