Nano-enhanced MC nylon composition

A composition and nano-type technology, applied in the field of engineering plastics, can solve the problems of glass fiber exposure, etc., and achieve the effects of improved physical properties, high rigidity, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

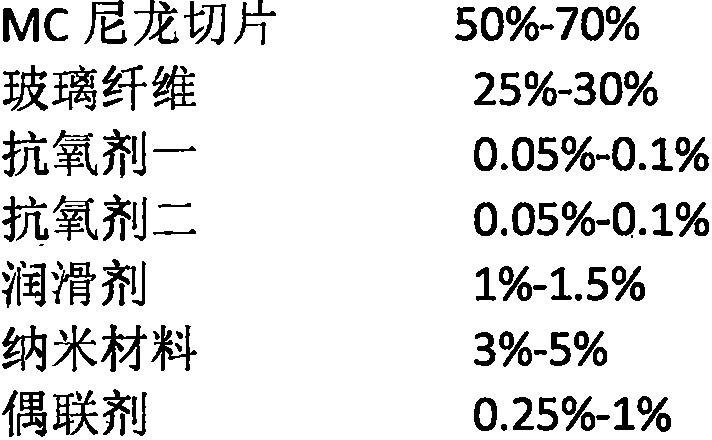

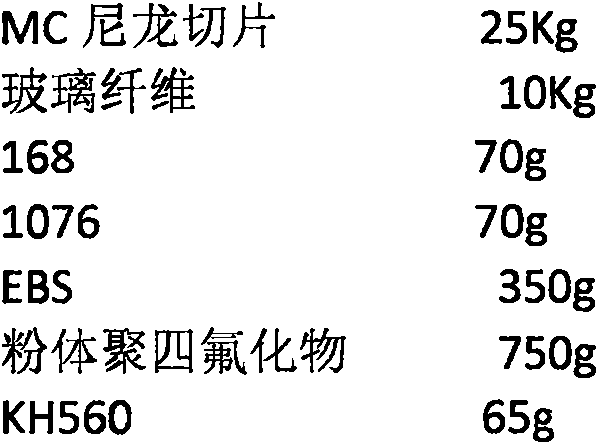

[0023] A nano-type reinforced MC nylon composition, which is obtained by blending the following main raw materials and extruding them at 215-250°C:

[0024]

[0025] The method for preparing the nanotype reinforced MC nylon composition of the present invention, its main steps are:

[0026] The first step, add 70g168, 70g1076, 350gEBS into the mixer and mix for 10 minutes, the resulting mixture is ready for use;

[0027] The second step is to dry the MC nylon slices at a temperature of 90°C for 6 hours;

[0028] The third step is to add 25Kg dried MC nylon chips, 10K glass fiber, the mixture obtained in the first step, 750g powdered polytetrafluoride and 65gKH560 into the extruder, and melt and extrude at 250°C to obtain the extrudate ;

[0029] The fourth step, the extrudate is cooled by water cooling;

[0030] The fifth step is dicing, grading, and packaging the finished product after cooling.

Embodiment 2

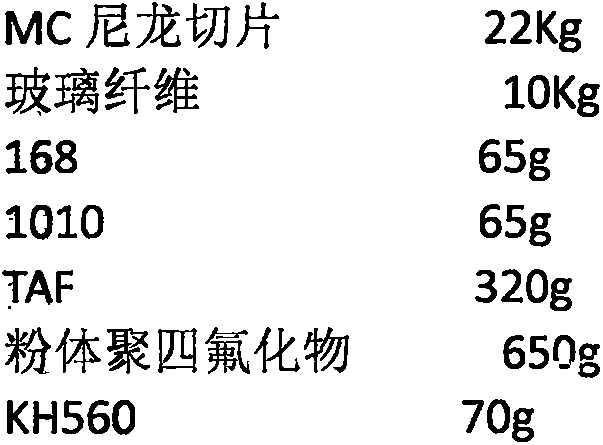

[0032] A nanometer reinforced nylon 6 composition, which is obtained by blending the following main raw materials and extruding them at 215-250°C:

[0033]

[0034] The method for preparing the nanotype reinforced MC nylon composition of the present invention, its main steps are:

[0035] In the first step, add 65g168, 65g1010, and 320gTAF into the mixer and mix for 1 minute, and the resulting mixture is set aside;

[0036] The second step is to dry the MC nylon slices at a temperature of 100°C for 5 hours;

[0037] The third step is to add 22Kg of dried nylon chips, 10Kg of glass fiber, the mixture obtained in the first step, 650g of powder polytetrafluoride and 70g of KH560 into the extruder, and melt and extrude at 240°C to obtain an extrudate;

[0038] The fourth step, the extrudate is cooled by water cooling;

[0039] The fifth step is dicing, grading, and packaging the finished product after cooling.

[0040] The raw materials and reagents involved in the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com