Shoe sole and preparation method of same

A technology of raw materials and vulcanization accelerators, applied in shoe soles, footwear, applications, etc., to achieve the effect of shortening vulcanization time, eliminating peculiar smell, and hard texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

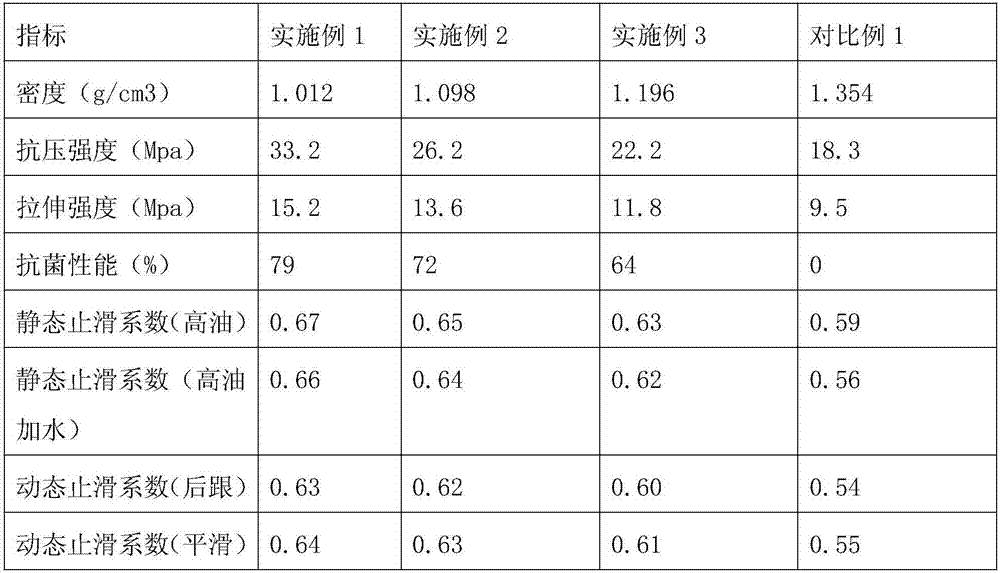

Examples

Embodiment 1

[0039] A kind of sole, comprises the raw material of following parts by weight: 15 parts of nitrile rubbers, 60 parts of brominated butyl rubbers, 17 parts of nano silicon dioxide, 2 parts of chlorinated polyethylene, 2.5 parts of polyethylene waxes, 0.6 parts of magnesium oxide, 2.5 parts of nano-zinc oxide, 1.3 parts of sulfur, 8 parts of nano-calcium carbonate, 7 parts of bentonite, 10 parts of bamboo charcoal, 12 parts of quartz glass fiber, 10 parts of polypropylene fiber, 1.3 parts of vulcanization accelerator, 6 parts of plasticizer, antioxidant 1.3 parts, 3 parts white smoke active agent, 2 parts coupling agent, 0.3 parts lubricant and 0.4 parts heat stabilizer.

[0040] Nano-calcium carbonate is added to the raw material. As a filler for the sole, the nano-calcium carbonate can improve the rheology of the sole material and improve its formability, toughness and strength.

[0041] Bentonite is added to the raw material, and bentonite has a certain adsorption capacity f...

Embodiment 2

[0057]A kind of sole, comprises the raw material of following weight part: 13 parts of nitrile rubber, 50 parts of brominated butyl rubber, 10 parts of nano-silica, 1 part of chlorinated polyethylene, 1 part of polyethylene wax, 0.2 part of magnesium oxide, 1 part of nano-zinc oxide, 0.6 part of sulfur, 6 parts of nano-calcium carbonate, 5 parts of bentonite, 7 parts of bamboo charcoal, 9 parts of quartz glass fiber, 7 parts of polypropylene fiber, 0.6 part of vulcanization accelerator, 4 parts of plasticizer, antioxidant 0.6 parts, 2 parts of white smoke active agent, 1 part of coupling agent, 0.2 parts of lubricant and 0.2 parts of heat stabilizer.

[0058] Nano-calcium carbonate is added to the raw material. As a filler for the sole, the nano-calcium carbonate can improve the rheology of the sole material and improve its formability, toughness and strength.

[0059] Bentonite is added to the raw material, and bentonite has a certain adsorption capacity for gas, liquid and o...

Embodiment 3

[0075] A kind of sole, comprises the raw material of following weight portion: 17 parts of nitrile rubbers, 70 parts of brominated butyl rubbers, 24 parts of nano silicon dioxide, 3 parts of chlorinated polyethylenes, 4 parts of polyethylene waxes, 1 part of magnesium oxide, 4 parts of nano zinc oxide, 2 parts of sulfur, 10 parts of nano calcium carbonate, 9 parts of bentonite, 13 parts of bamboo charcoal, 15 parts of quartz glass fiber, 13 parts of polypropylene fiber, 2 parts of vulcanization accelerator, 8 parts of plasticizer, antioxidant 2 parts, white smoke active agent 4 parts, coupling agent 3 parts, lubricant 0.4 part and heat stabilizer 0.6 part.

[0076] Nano-calcium carbonate is added to the raw material. As a filler for the sole, the nano-calcium carbonate can improve the rheology of the sole material and improve its formability, toughness and strength.

[0077] Bentonite is added to the raw material, and bentonite has a certain adsorption capacity for gas, liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com