Hollow tire

A hollow and cavity technology, used in tire measurement, non-pneumatic tires, tire parts, etc., can solve the problems of poor wear resistance and high cost, and achieve the effect of simple shape, less maintenance, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

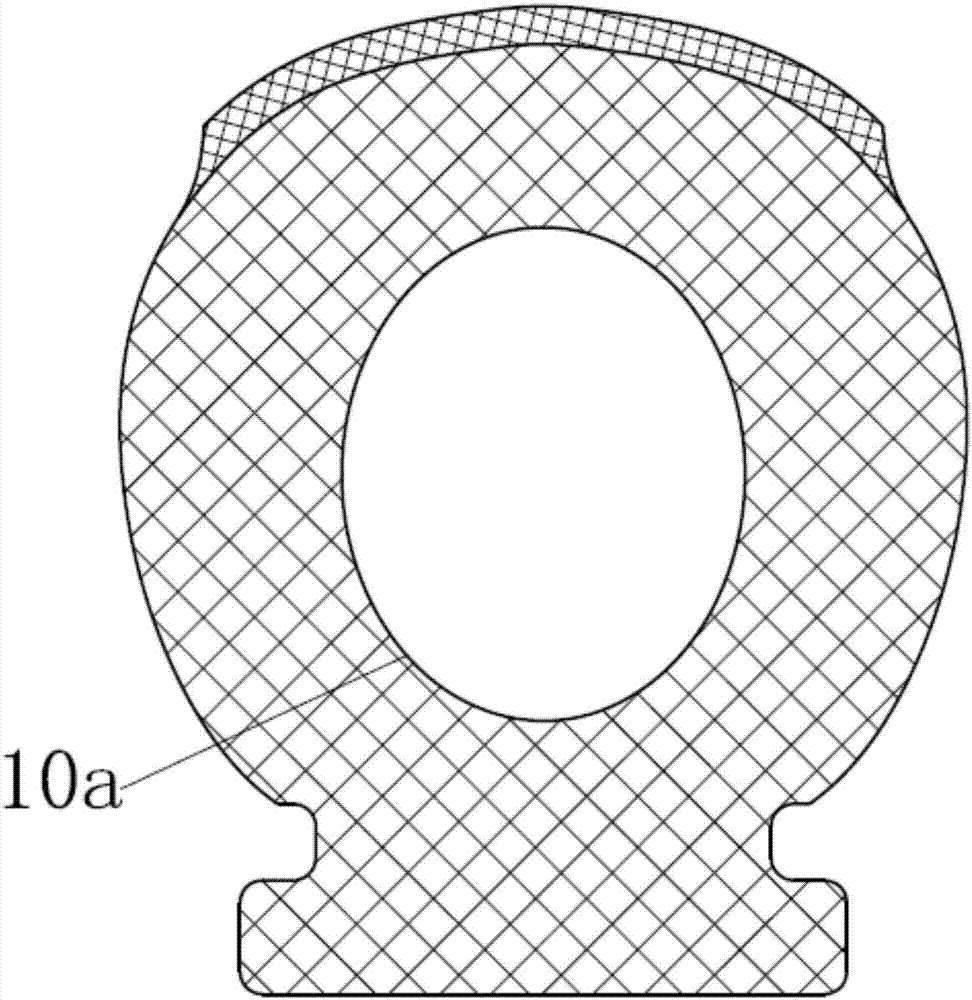

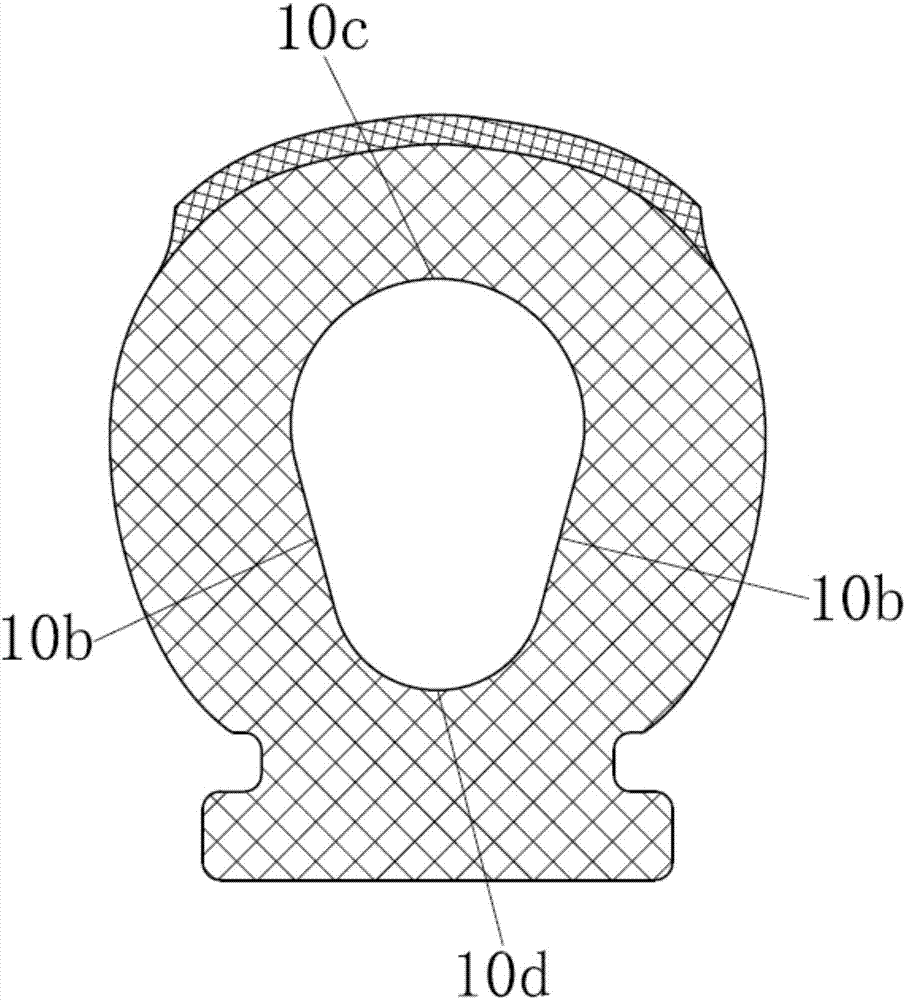

[0036] In order to achieve the purpose of the present invention, figure 1 A cross-sectional view of an embodiment of the present invention is shown. A hollow tire, comprising a crown 7, a carcass 1, and a fetal toe 4; a cavity 2 runs through the carcass 1, and the cavity 2 accounts for 20% to 50% of the total cross-sectional area of the carcass 1 cross section.

[0037] The beneficial effects of adopting the above technical solution are: the present invention does not need to be inflated, requires less maintenance, and has the anti-stamp function. The material of the carcass can adopt the same grade of rubber as the outer tire of the ordinary tire in the prior art, which can have the same wear resistance as the existing outer tire, and the thickness of the carcass is thick, which is equivalent to having a thicker wear-resistant layer. It has a longer ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com