Negative pressure precision injection molding method for mobile phone plastic parts

A technology of injection molding and plastic parts, applied in coating and other directions, can solve the problems that affect the performance and surface quality of plastic parts of mobile phones, the products are easy to stick to the fixed template, and the size of injection molding cannot be processed, so as to achieve good radiation resistance and cost performance. High, prevent deformation and damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

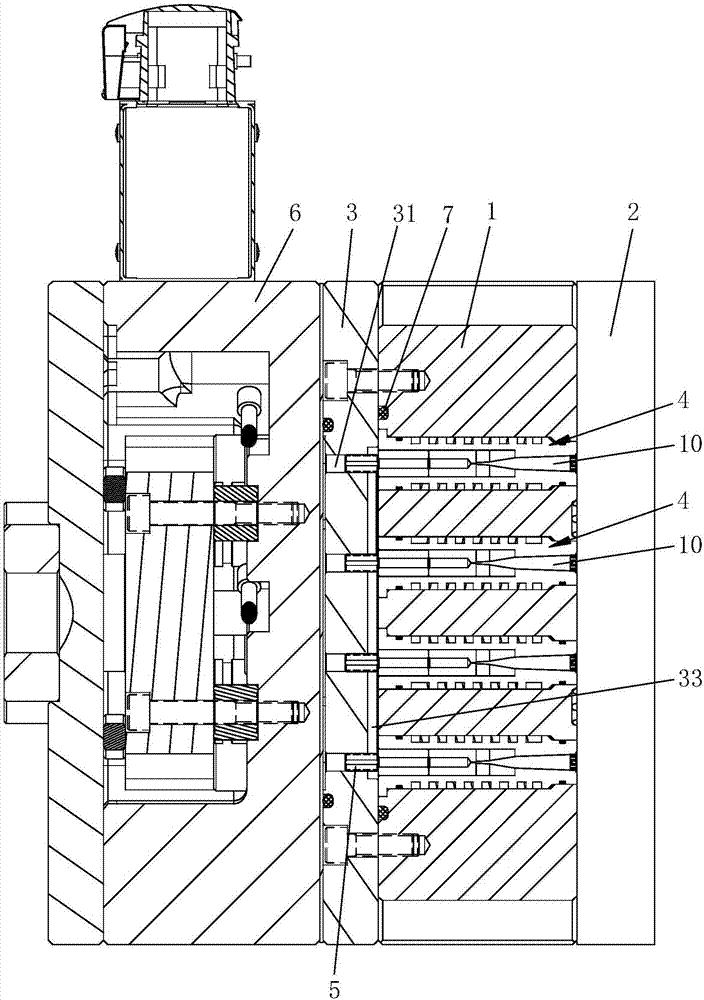

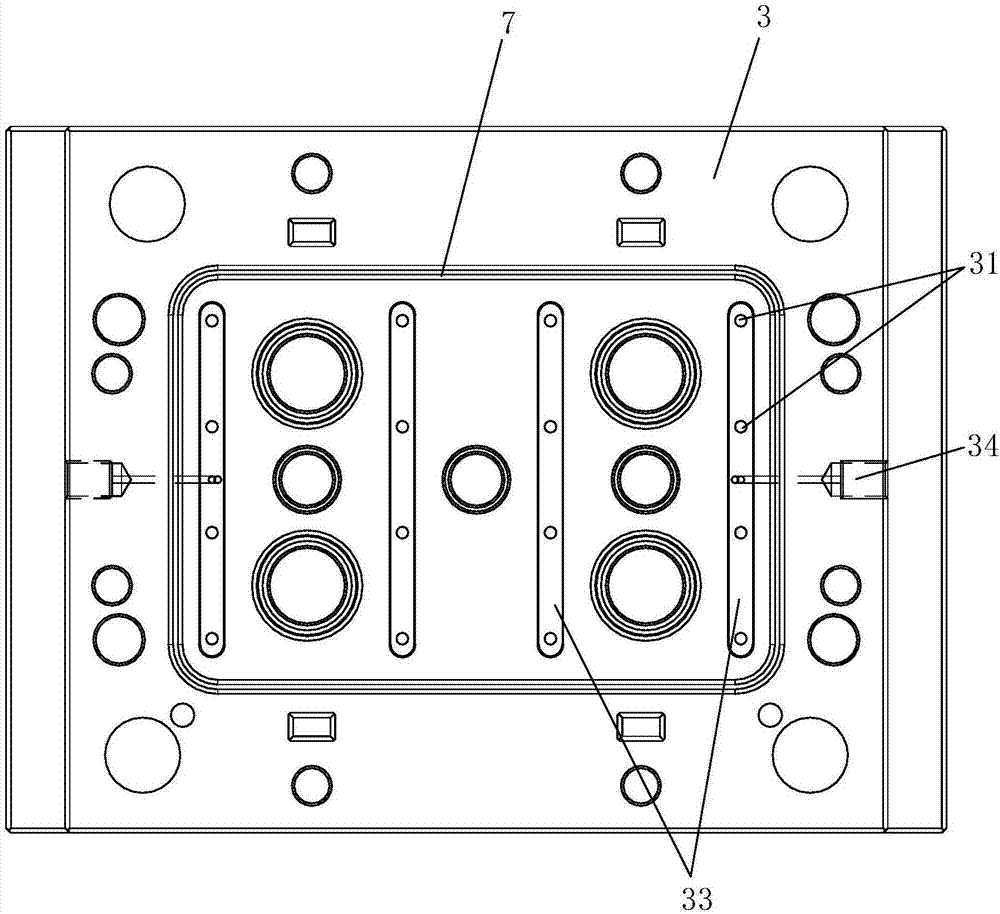

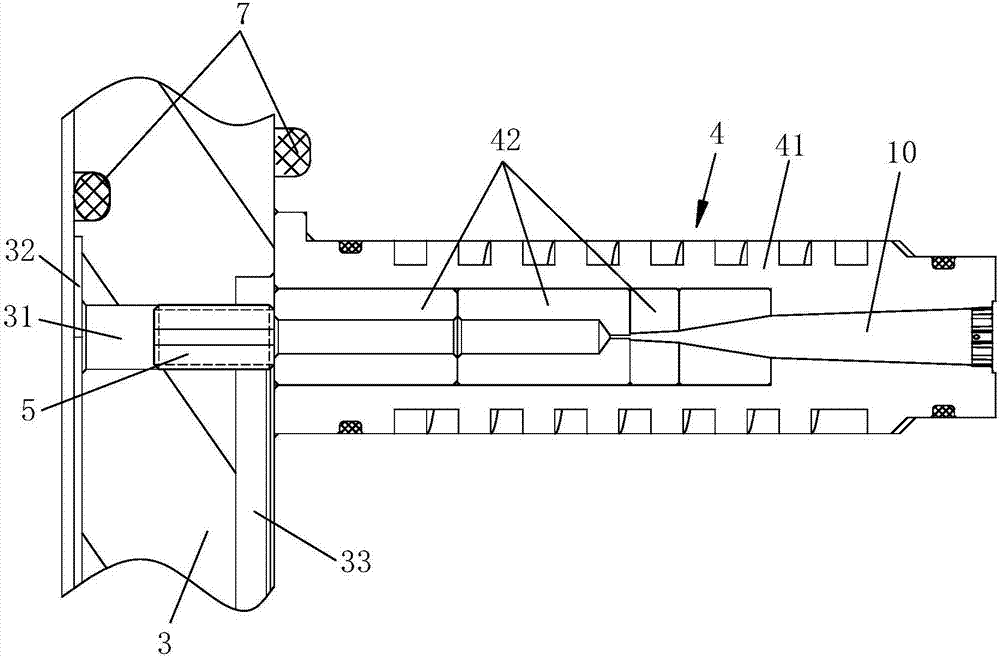

[0021] The present invention will be further described below in conjunction with accompanying drawing and preferred embodiment, see Figure 1~3 As shown, in the negative pressure precision injection molding method for mobile phone plastic parts of the present invention, the molding mold adopted includes a fixed template 1, a movable template 2 matched with the fixed template 1, the movable template 2 is arranged on the rear end surface of the fixed template 1, and the fixed template 1 is provided with a plurality of cavity 10 inside, and a cover plate 3 is provided on the front surface of the fixed template 1, and a plurality of inlet and outlet air holes 31 respectively corresponding to the plurality of mold cavities 10 are opened on the cover plate 3, and each inlet and outlet air hole 31 is respectively It communicates with the corresponding mold cavity 10, and the multiple inlet and outlet air holes 31 communicate with each other through the ventilation groove 32, and the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com