Automatic conveying belt blanking production equipment

A technology for production equipment and conveyor belts, which is applied in the field of automatic conveyor belt blanking production equipment, can solve the problems of unsuitable waste belts, etc., and achieve the effects of increasing service life, reducing costs, and improving per capita work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

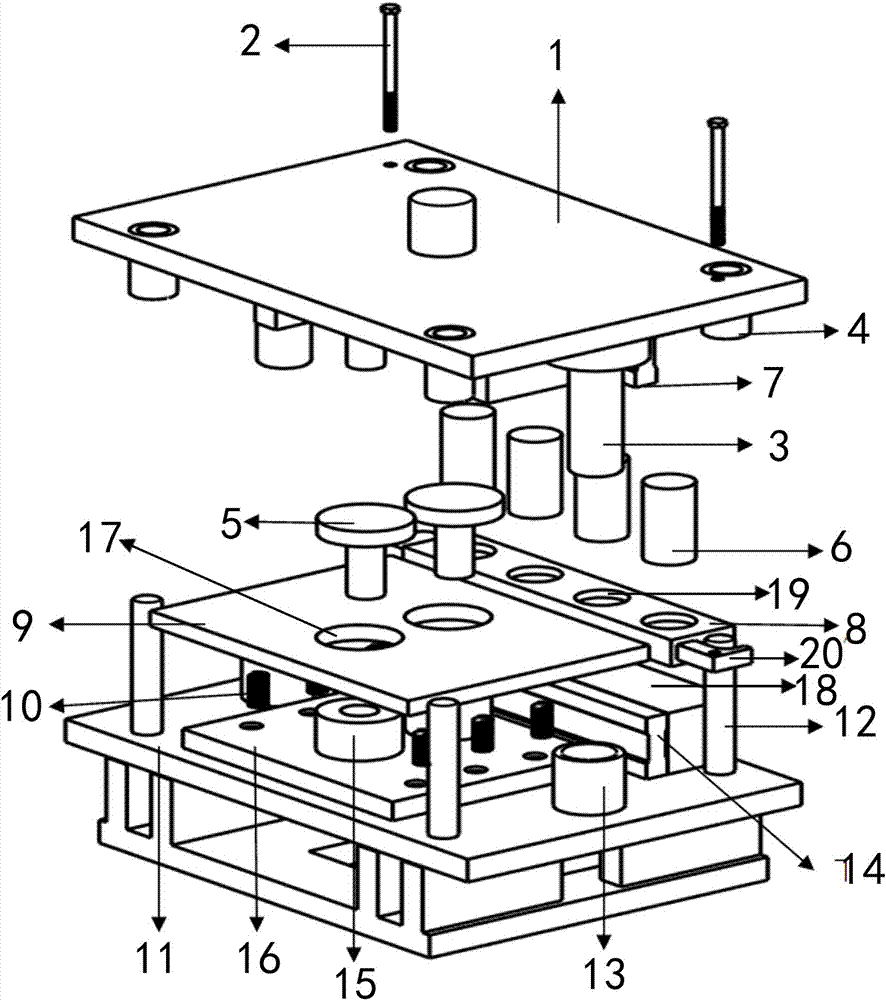

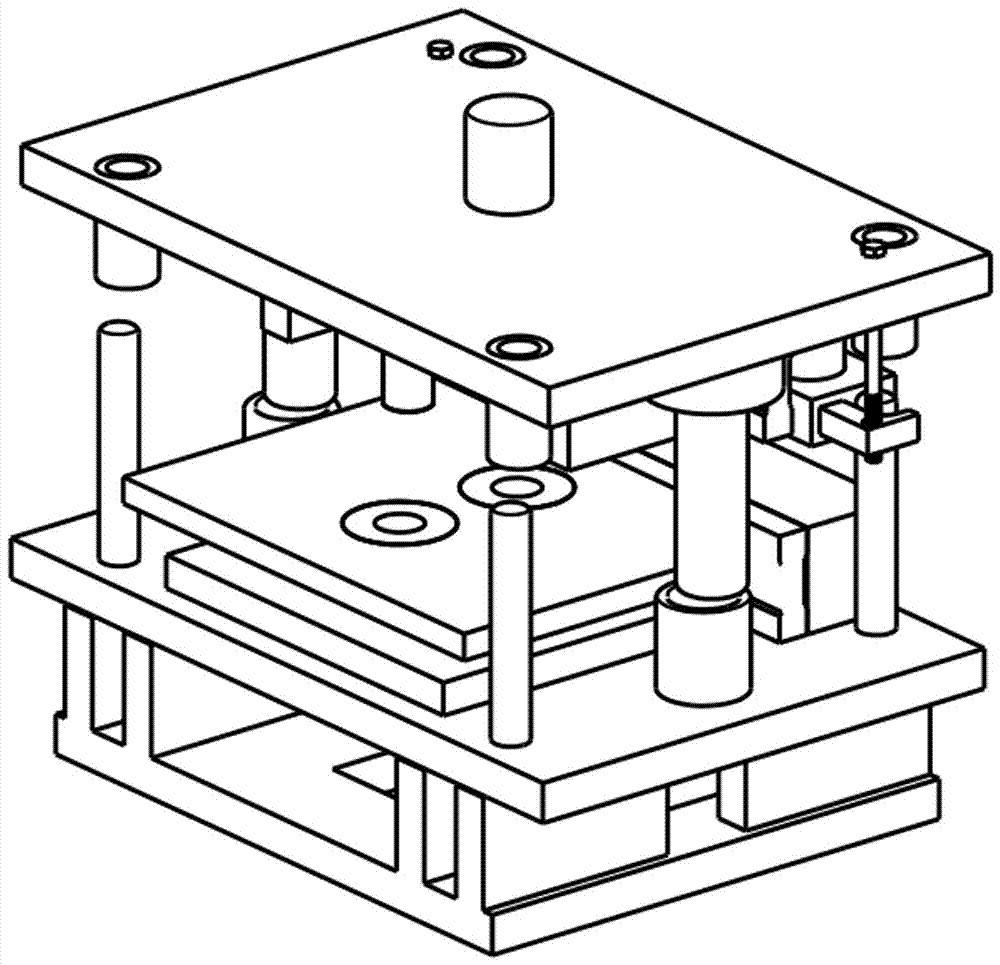

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

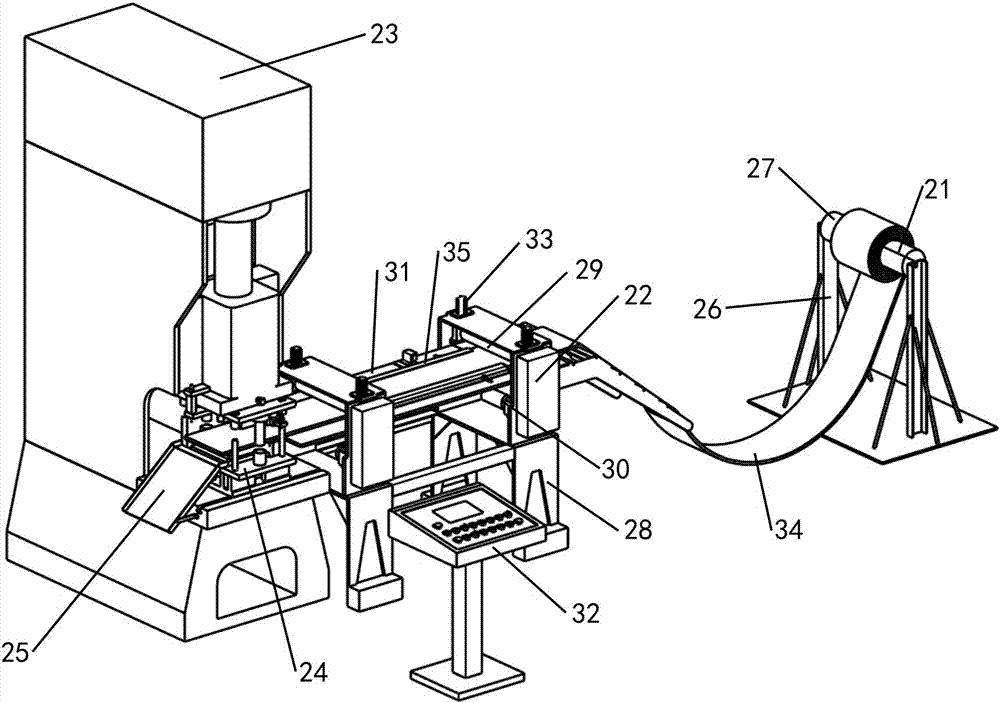

[0036] refer to Figure 1-4 , a kind of automatic conveyer belt blanking production equipment described in this specific embodiment includes a belt rack 21 for winding and placing the belt; a hydraulic press 23 to provide power; a mold 24 installed on the hydraulic press 23 to drive the upper template through the hydraulic press 23 Contact with the lower template fixed on the base to realize belt cutting and punching; belt automatic transmission device 22 automatically transmits the belt on the belt rack 21 to the mold 24.

[0037]The automatic conveyor belt blanking production equipment also includes a slide plate 25, and the slide plate 25 is connected behind the mold 24.

[0038] The belt rack 21 includes a support 26 and a reel 27 mounted on the support 26 , and the belt is wound on the reel 27 .

[0039] The belt automatic transmission device 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com