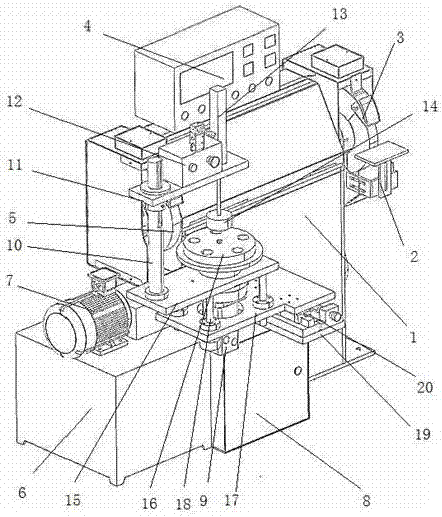

Semi-automatic disc grinding machine

A grinding machine and semi-automatic technology, applied in the field of grinding machines, can solve the problems of reduced work efficiency and low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0008] The invention provides a semi-automatic disc grinding grinder. Semi-automatic auxiliary equipment for disc processing is arranged on one side of the grinder. The semi-automatic auxiliary equipment improves the processing efficiency of disc workpieces, thereby improving the overall production efficiency.

[0009] As an embodiment of the present invention, the present invention provides a semi-automatic disc grinding grinder, comprising a grinder main body 1, a working grinding wheel 3, a console 4, a working grinding wheel 2 5, an electrical working box 8, a rotation control device 9, Pillar 10, upper support plate 11, rotary cylinder 13, rotary platen 14, middle support plate 15, rotary work plate 16, lower support plate 17, connecting rod 18, fixed bracket 19 and linear motion guide 20, the grinder The rotating shaft on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com