Plate spring quality detection device for achieving on-line plate spring rolling data measuring

A detection device, measuring board technology, applied in the direction of measuring device, length measuring device, conveyor control device, etc., can solve the problems of long required time, lagging response time, long equipment time, etc., achieve short reaction time and reduce fuel consumption The effect of using and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

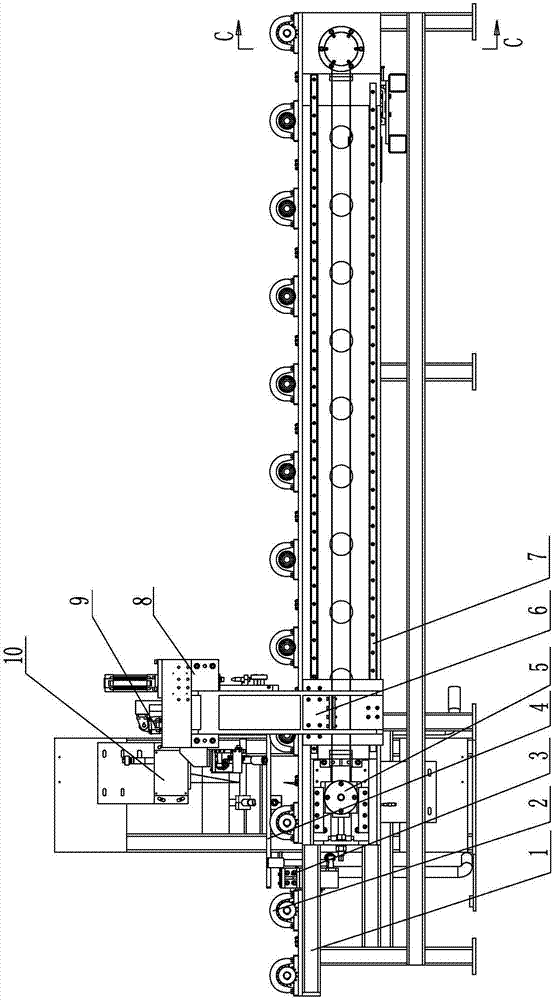

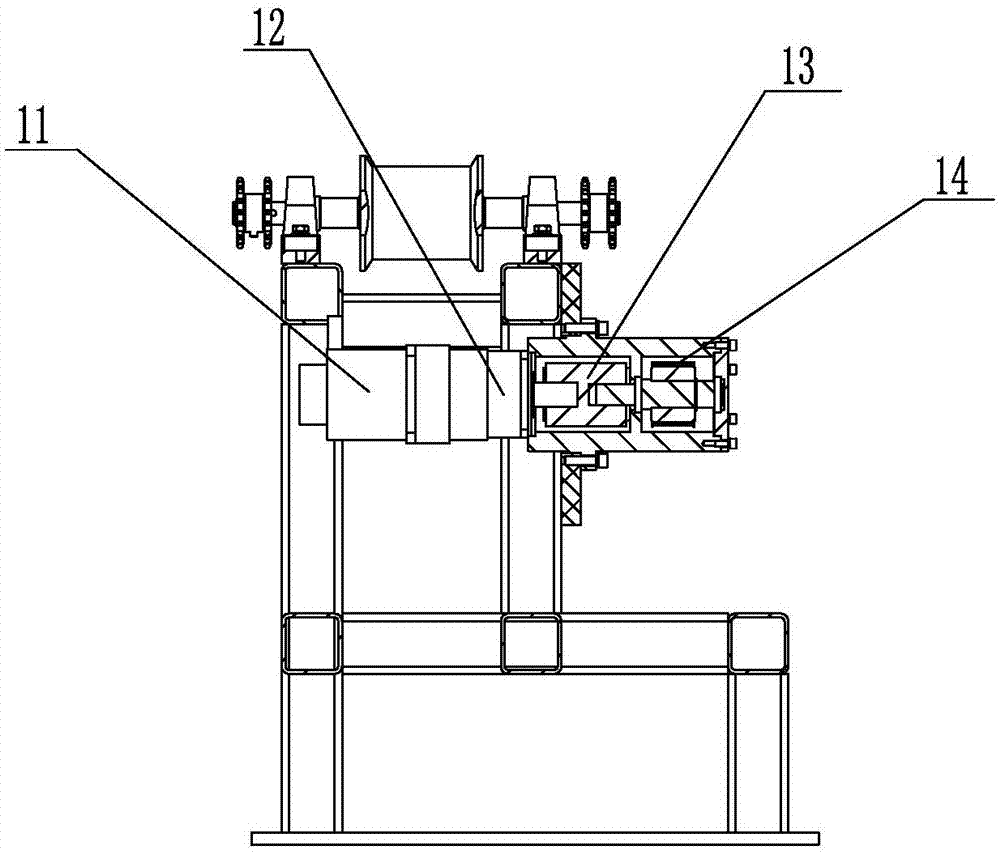

[0035] Such as Figure 1-Figure 4 , Figure 14 As shown, the leaf spring quality detection device for realizing on-line measurement of leaf spring rolling data according to the present invention includes a frame 1 on which conveying rollers 2 are arranged, and the conveying rollers 2 are equidistant from the front end of the frame to the end of the frame Set up multiple, adjacent two conveying rollers 2 are connected by a transmission chain and a transmission sprocket, the conveying roller 2 at the end of the frame is connected to the roller drive motor 16 through a transmission chain and a traditional gear, and passes through the roller table fixed at the end of the frame Drive motor 16 for transmission, the end of the frame is also provided with a servo motor 11, the servo motor 11 is connected to the reducer 12, the reducer 12 is connected to the synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com