A double-stator hybrid excitation motor

A hybrid excitation motor, double stator technology, applied in synchronous machines, electromechanical devices, electrical components, etc., can solve the problems of small constant power speed regulation range, poor magnetic weakening effect, etc., to reduce equivalent reluctance and improve utilization. , the effect of improving the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

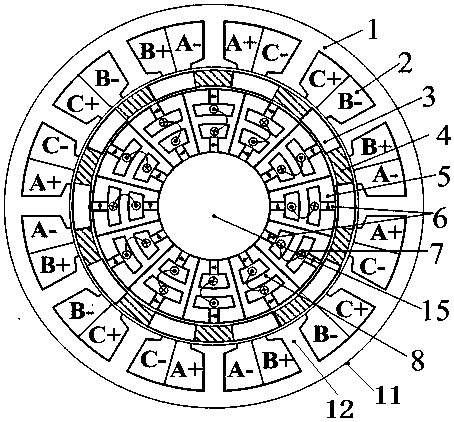

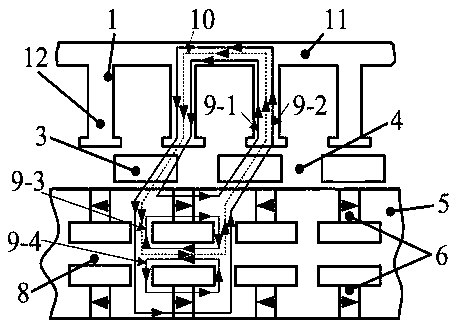

[0026] see figure 1 , the present invention includes an outer stator 1, an intermediate rotor, an inner stator and a rotating shaft 15, wherein the intermediate rotor is formed by staggering and fixedly connecting 10 rotor magnetic conductive blocks 3 and non-magnetic conductive materials 4 of the same number along the circumferential direction, and the inner stator It consists of 12 inner stator cores 5 with the same fan-shaped structure closely attached to each other. The inner stator, the rotor and the outer stator 1 are coaxially sheathed on the outside of the rotating shaft 15 in sequence. The outer stator 1, the rotor magnetic block 3 and the inner stator core 5 are all laminated with silicon steel sheets.

[0027] The outer stator 1 is composed of an outer stator yoke 11 and outer stator teeth 12, and the outer stator yoke 11 is evenly arranged with 12 outer stator teeth 12 along the circumferential direction. The outer stator slots are formed between two adjacent ou...

Embodiment 2

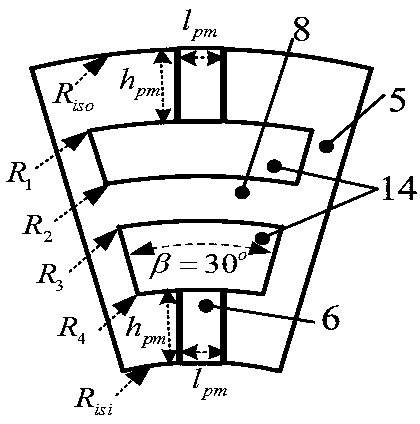

[0043] see Figure 8 and Figure 9 The difference between Embodiment 2 and Embodiment 1 of the present invention is that only one fan-shaped inner stator is opened on the inner stator core 5 between the inner permanent magnet 6 and the outer permanent magnet 6 on the same inner stator core 5 Slot 14. The centerline of the one inner stator slot 14 also coincides with the centerline of the inner stator core 5 , and the fan-shaped circle center of the inner stator slot 14 also coincides with the circle center of the inner stator core 5 . The opening angle of the inner stator slot 14 is still β =30 o , the inner edge of the permanent magnet 6 on the outside is tangent to the outer edge of the one inner stator slot 14, but there is a distance between the outer edge of the permanent magnet 6 on the inner side and the inner edge of the one inner stator slot 14, the inner stator slot The inner stator core 5 between 14 and the permanent magnet 6 on the inner side is a magnetically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com