Large-power-density compact-type motor for mining blower fan

A compact and high-power technology, applied in the field of electric motors, can solve the problems of large size and low efficiency, and achieve the effects of improving overall performance, improving heat dissipation capacity, and reducing startup temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

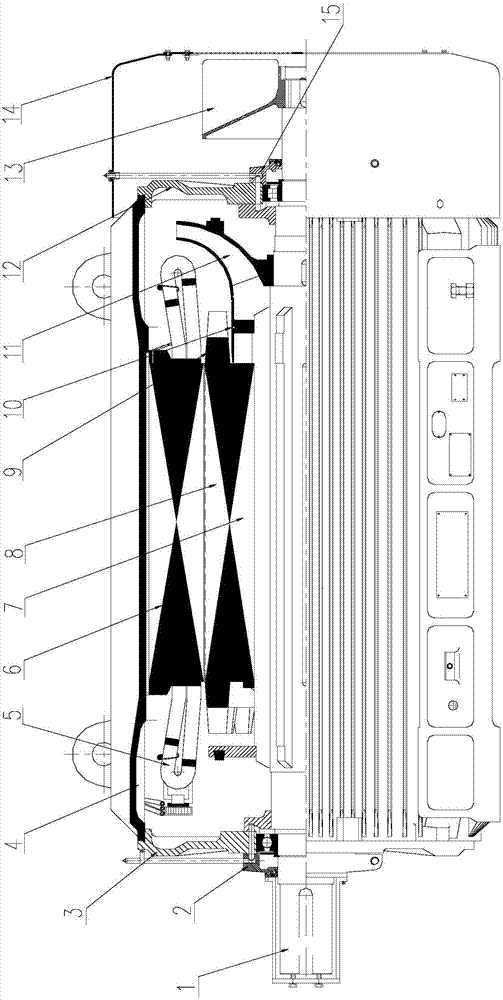

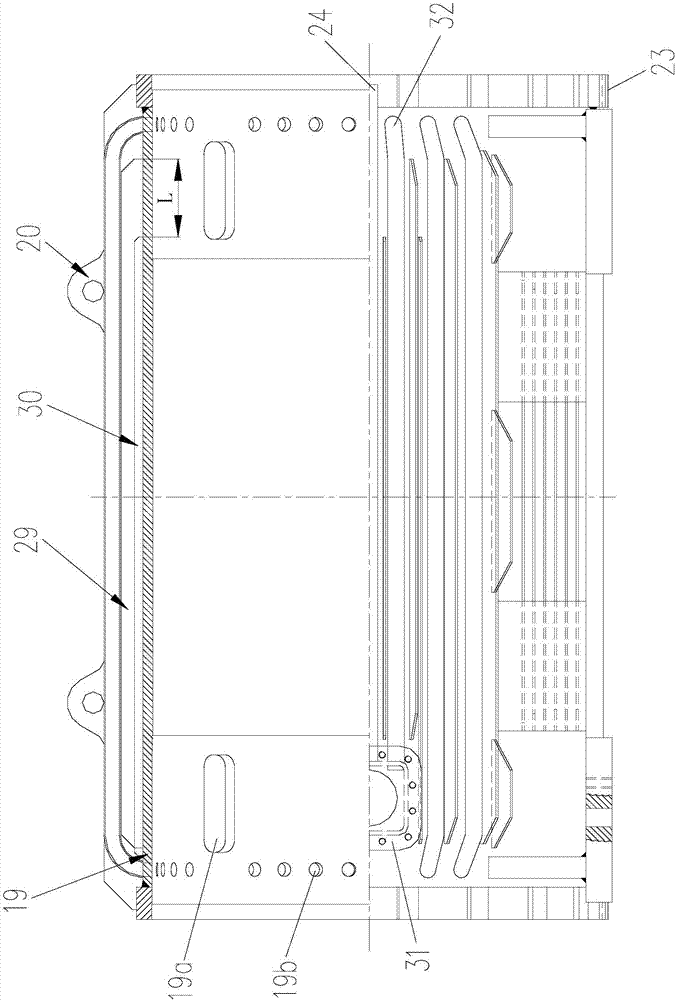

[0022] Such as Figure 1 to Figure 4Shown: the high power density compact mine fan motor of this embodiment includes a stator, a rotor, and a cooling device; the stator includes a base 4 and a winding stator core arranged inside the base 4; the rotor includes Shaft 1 and the squirrel-cage rotor arranged on the shaft 1, one end of the shaft 1 protrudes out of the machine base to form a shaft extension end, and the other end is located in the end cover 14 of the machine base 4 or extends out of the end cover 14 to form a non-shaft extension end, the shaft end and the non-shaft end are respectively supported in the stator through the end cover assembly; Inside the seat 4, and fixed on the shaft 1, the air guide tube 10 communicates with the inner fan 11, and the outer fan 13 is located in the end cover 14, and is fixed on the non-extending end of the shaft 1. The electromagnetic torque generated by the squirrel cage rotor is transmitted to the load driven by the motor, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com