Modeling quality monitoring method and system based on model prediction controller

A technology for model prediction and quality monitoring, applied in testing/monitoring control systems, general-purpose control systems, and control/regulating systems, etc., can solve the problem of low monitoring accuracy, process model mismatch and interference model mismatch, and cannot be diagnosed. The performance of the controller deteriorates and other problems, to achieve the effect of high feasibility, small impact, and low resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

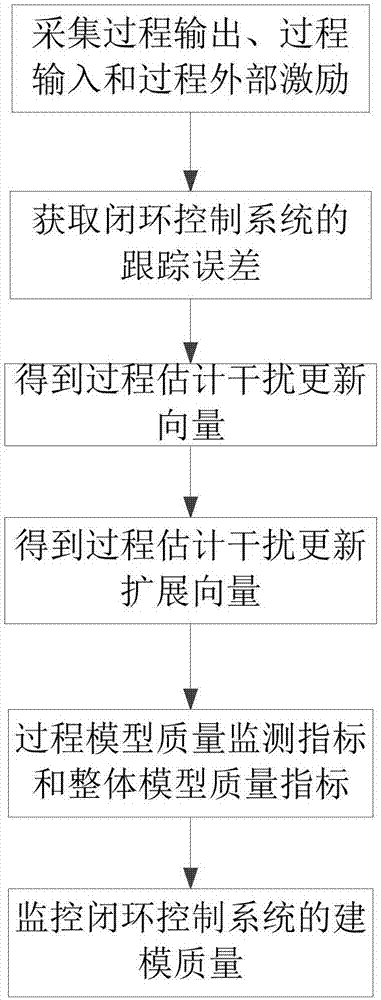

Method used

Image

Examples

Embodiment 1

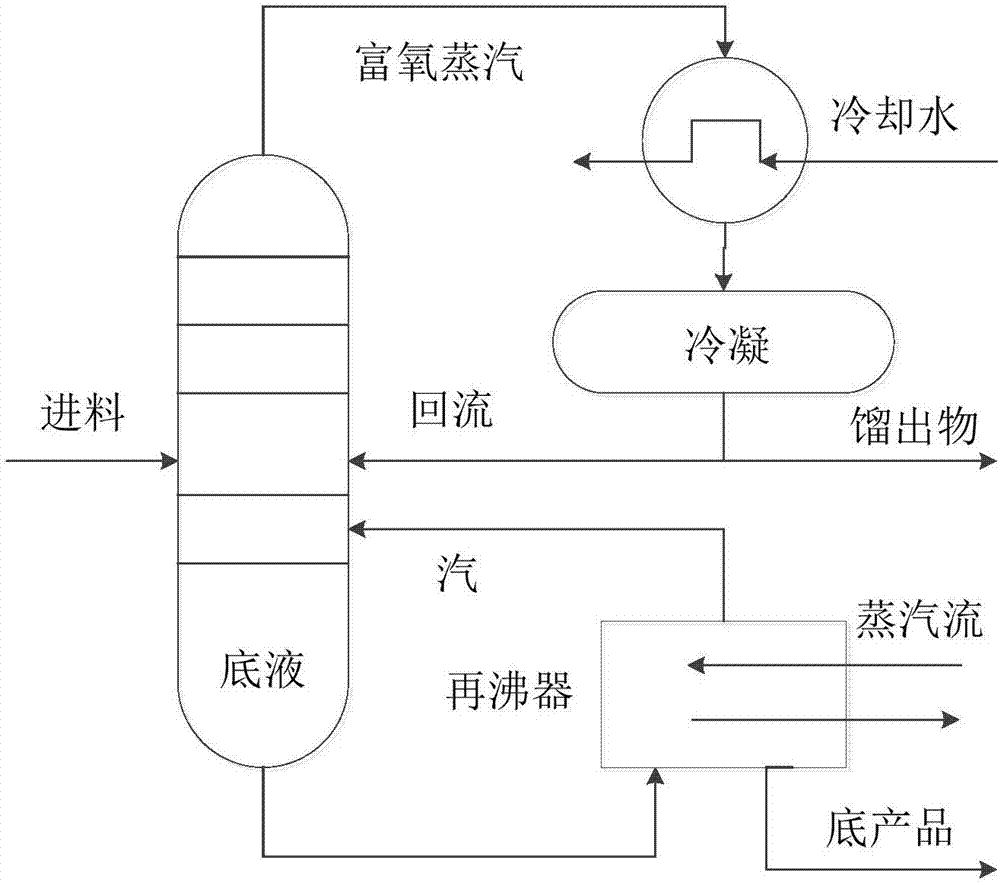

[0108] The Wood-Berry distillation column is a typical multiple-input and multiple-output system with large pure lag; the process is as follows image 3 As shown, the output is the overhead concentration X D (s) and the bottom liquid phase concentration X B (s), controlled by the top reflux flow R(s) and the bottom reboiler steam volume S(s); the process model is:

[0109]

[0110] Among them, s represents the Laplacian operator.

[0111] The process transfer function matrix of the Wood-Berry distillation column is:

[0112]

[0113] Among them, s represents the Laplacian operator.

[0114] The process sampling time is 1min / time, and the discretized process transfer function matrix is:

[0115]

[0116] Among them, q is a mathematical operator representing discretization.

[0117] The interference model takes the following diagonal matrix:

[0118]

[0119] Utilize the improved modeling quality monitoring method based on the model predictive controller provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com