Fully-automatic infiltration cleaning line control system

A technology of control system and electrical control system, applied in the field of automatic impregnation and cleaning line control system, can solve the problems of reducing product qualification rate, leakage, increasing production cost, etc., and achieves the effect of low-cost investment and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Automatic impregnation cleaning line control system includes:

[0015] Machine exhaust system (fog condensation device)

[0016] In view of the phenomenon that the impregnation line is easy to generate water mist, this system has settings on both hardware and control software, which effectively controls the overflow of water mist and ensures the working environment of the workshop. After extraction, it condenses into a liquid.

[0017] recycling system

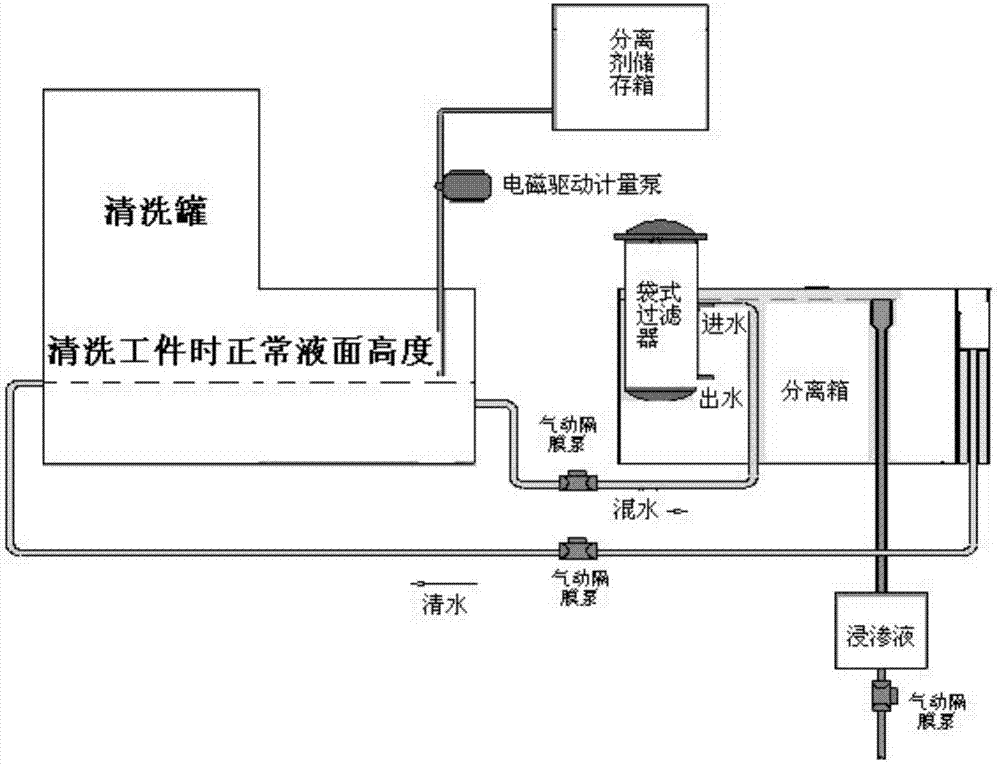

[0018] This system is a unique impregnating liquid recycling device with low cost investment and high benefit return. It can receive the cleaning water mixed with impregnating agent from the washing tank, first pass through the filter, and then separate the two, The impregnation agent is pumped back into the impregnation tank for recycling, and the purified water is also pumped directly back into the glue washing tank to continue cleaning the workpiece. There is no need for long-term waste water discharge, and a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com