Intelligent frost-crack prevention pipeline connecting equipment for industrial building of large smart city

一种工业建筑、智能管道的技术,应用在建筑、法兰连接、管道保护等方向,能够解决增加管道重量、管道易被冻裂、管道易受损等问题,达到结构稳固、避免热量损失、提高安全性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

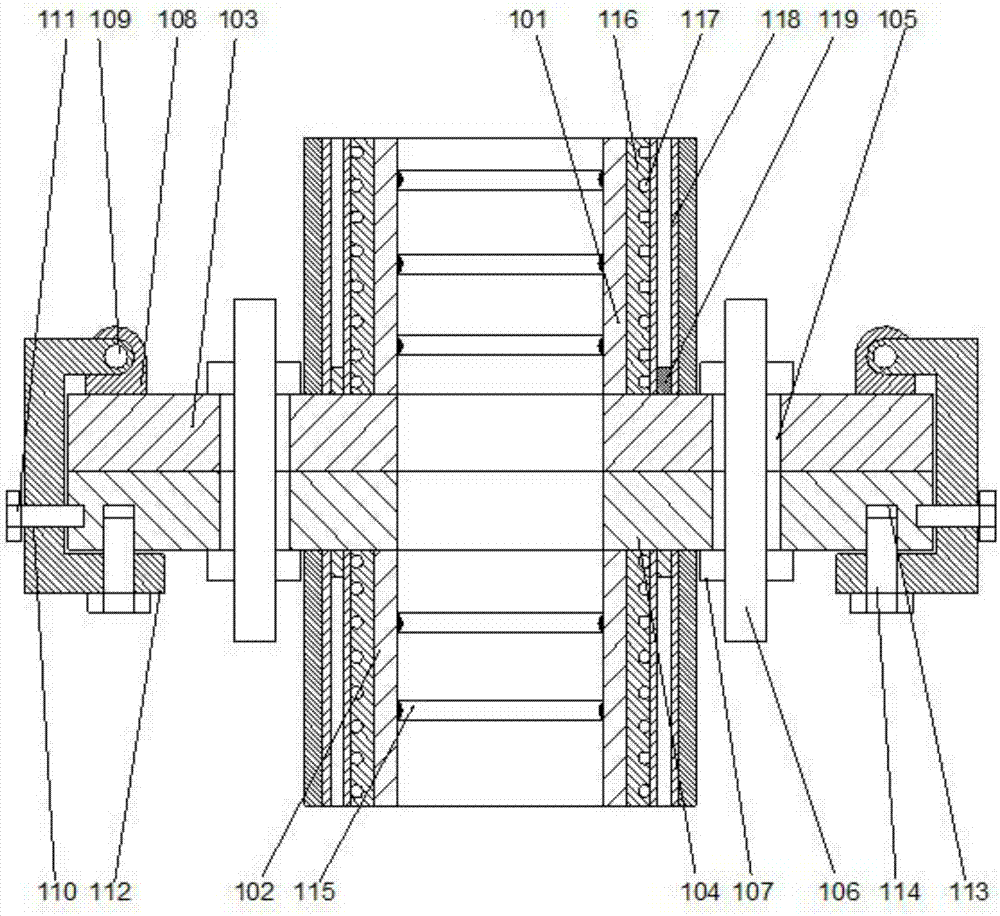

[0019] Such as figure 1 As shown, a kind of anti-freezing and cracking intelligent pipeline connection equipment for large-scale smart city industrial buildings includes a first connecting sleeve 101 and a second connecting sleeve 102, and the first connecting sleeve 101 and the second connecting sleeve The sleeves 102 are all hollow cylindrical structures, and a protective cover 116 is set on the outside of the first connecting sleeve 101 and the second connecting sleeve 102. The inner wall of the protective cover 116 is provided with a spiral A heating tank arranged in a shape, a heating wire 117 is arranged in the heating tank, the protective cover 116 has an inner and outer two-layer structure, and the heating tank is located on the inner wall of the inner layer structure of the protective cover 116 , a cavity is provided between the inner and outer two-layer structure, heat-insulating sponges 118 are respectively bonded on the opposite end faces of the inner and outer two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com