High formwork

A high-support formwork and vertical plate technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve major construction safety accidents, mass deaths and injuries of workers, and high Unevenness and other problems, to achieve the effect of strong bearing and compressive capacity, increased strength and bearing capacity, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0024] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

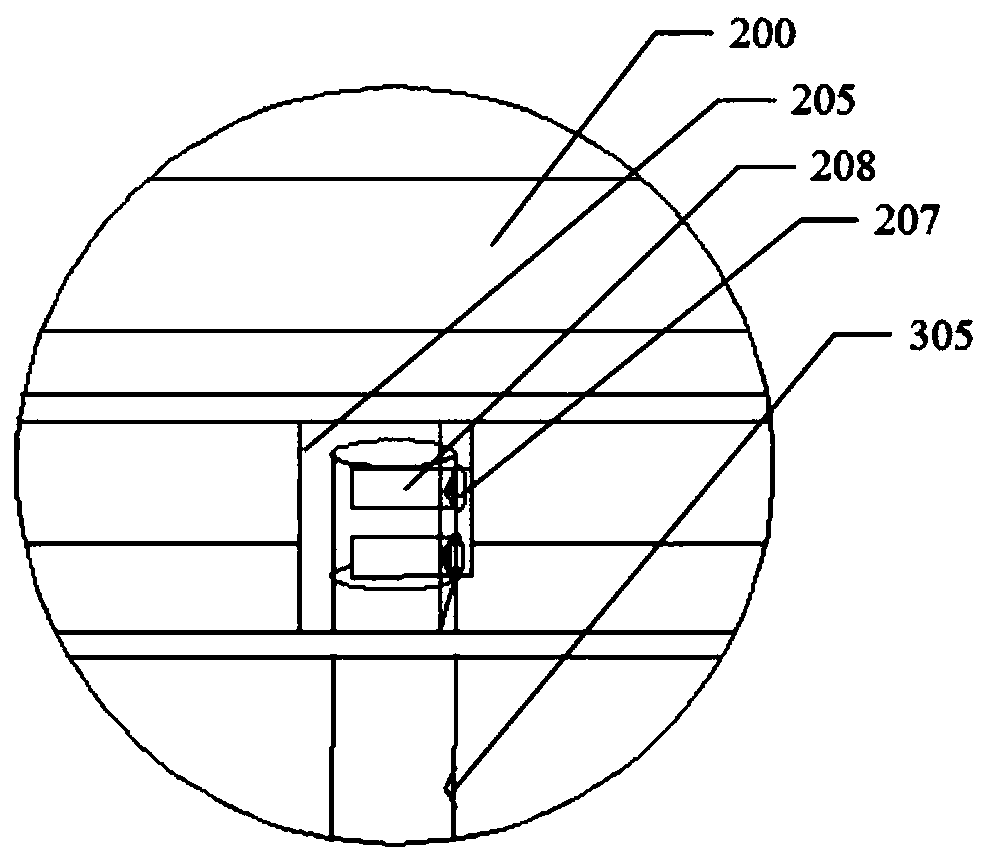

[0025] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a kind of high support mold, comprising:

[0026] Vertical plate 100, which is a rectangular plate, several first fixing holes 101 are evenly distributed on both sides of the vertical plate 100; the first through hole 102 extending longitudinally along the vertical plate 100 is arranged in the vertical plate 100, and the first through hole 102 extends longitudinally along the vertical plate 100. The number of through holes 102 is set to be at least two.

[0027] Horizontal bar 200, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com