High-speed train ballastless track board general accurate measurement prism support

A technology of ballastless track and prism, which is applied in the direction of track, track maintenance, track superstructure, etc., can solve the adverse effects of atmospheric refraction precision measurement accuracy, increase the difficulty of fine measurement software observation data processing, and reduce the efficiency of fine adjustment operations, etc. Achieve the effect of strong field wind resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that they are consistent with the directions of up, down, left and right of the drawings themselves, and do not limit the structure.

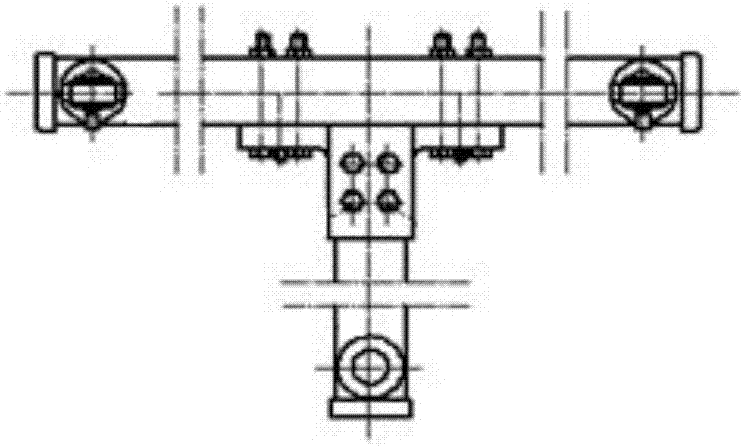

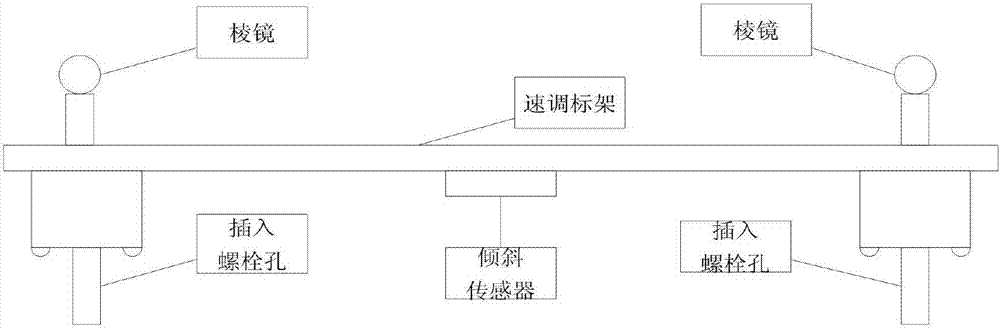

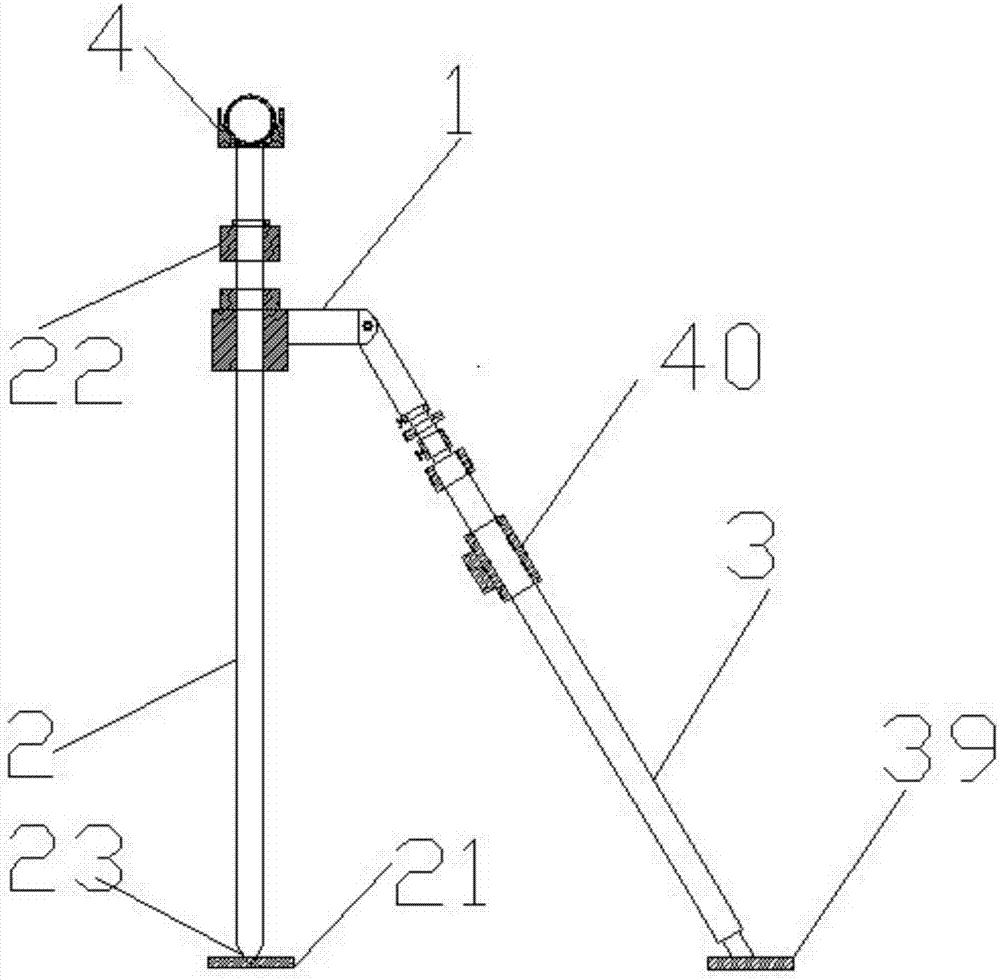

[0053] Such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the load-bearing scaffold includes a support platform 1, a centering rod 2 connected to the support platform, and two support feet 3. The centering rod is made of thick and long 304 stainless steel pipes, and the support platform is an isosceles right angle Triangular shape, the centering rod is fixed at the right angle of the support platform, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com