Seedling raising substrate for organic rice prepared by using furfural residue, preparation method for seedling raising substrate and application of seedling raising substrate

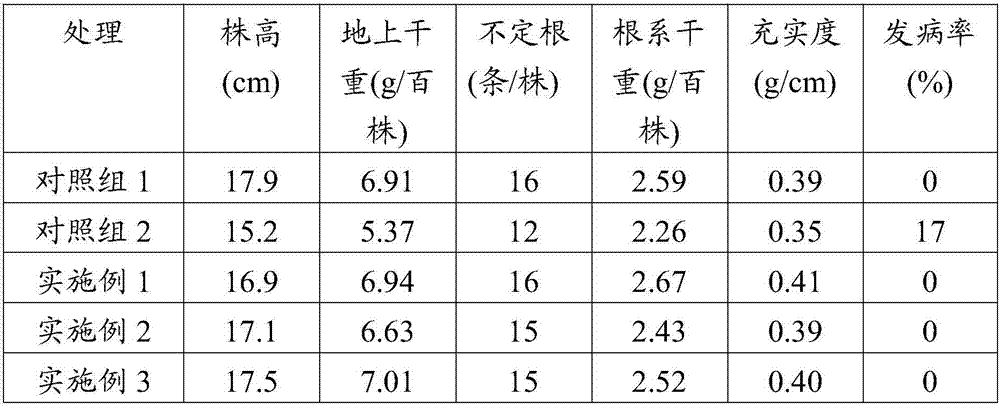

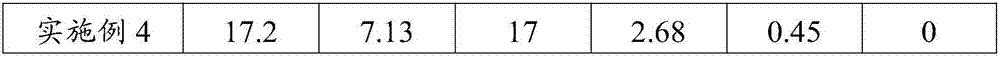

A technology for raising seedling substrate and organic rice, applied in the field of raising seedling substrate, can solve problems such as increasing difficulty and cost, and achieve the effects of a large number of adventitious roots, a high degree of enrichment, and the prevention of blight disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a preparation method of the seedling-raising substrate described in the above-mentioned technical solution, comprising the following steps:

[0039] 1) After mixing furfural slag, straw charcoal, chicken manure and water, heap fermentation to obtain fermentation substrate;

[0040] 2) drying and pulverizing the fermented substrates obtained in the step 1) successively to obtain pulverized substrates;

[0041] 3) mixing the pulverized substrate obtained in the step 2) with wood vinegar, phosphate rock powder and potassium mineral powder to obtain a seedling-raising substrate for organic rice.

[0042]In the present invention, the mixture obtained by mixing furfural slag, straw charcoal, chicken manure and water is built up and fermented to obtain a fermentation substrate. In the present invention, the mixing method is not particularly limited, and a conventional mixing method may be used. Preferably, in the obtained mixture, water ac...

Embodiment 1

[0062] Furfural slag with a water content of 30wt%, straw charcoal, chicken manure with a water content of 60wt%, and water were mixed and piled up, covered with a plastic film, and fermented at a temperature of 10°C for 33 days. During the fermentation period, the pile was turned every 4 days to obtain a fermentation substrate. The volume ratio of the furfural residue, straw charcoal and chicken manure is 3:1:1, and the amount of water added is 50% of the total mass of the furfural residue, straw charcoal, chicken manure and water.

[0063] The obtained fermentation substrate was dried at 80°C to obtain a dry substrate with a water content of 35%. The obtained dry matrix was pulverized into a pulverized matrix with a particle size of 3 mm.

[0064] The obtained pulverized substrate is mixed with wood vinegar, phosphate rock powder with a particle diameter of 2 mm and potassium mineral powder with a particle diameter of 0.8 mm to obtain a seedling-raising substrate for organic...

Embodiment 2

[0068] Furfural slag with a water content of 40wt%, straw charcoal, chicken manure with a water content of 40wt%, and water were mixed to build a pile, covered with a plastic film, and fermented at a temperature of 25°C for 27 days. During the fermentation period, the pile was turned every 2 days to obtain a fermentation substrate. The volume ratio of the furfural residue, straw charcoal and chicken manure is 8:1:1, and the amount of water added is 70% of the total mass of furfural residue, straw charcoal, chicken manure and water.

[0069] The obtained fermentation substrate is dried in the shade at 10-25° C. in a cool and ventilated place to obtain a dry substrate with a water content of 30%. The obtained dried matrix was pulverized into a pulverized matrix with a particle size of 1 mm.

[0070] The obtained pulverized substrate is mixed with wood vinegar, phosphate rock powder with a particle diameter of 0.5 mm and potassium mineral powder with a particle diameter of 2 mm t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com