A method for depth reduction of excess activated sludge

A technology for residual active sludge, which is applied in sludge treatment, sludge treatment, oxidation treatment of sludge, etc., can solve the problems of low cracking efficiency, low reduction rate, and large dosage of chemicals for residual activated sludge, and achieve reduction Amount of remaining activated sludge and treatment cost, low treatment cost, effect of reducing water content and organic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

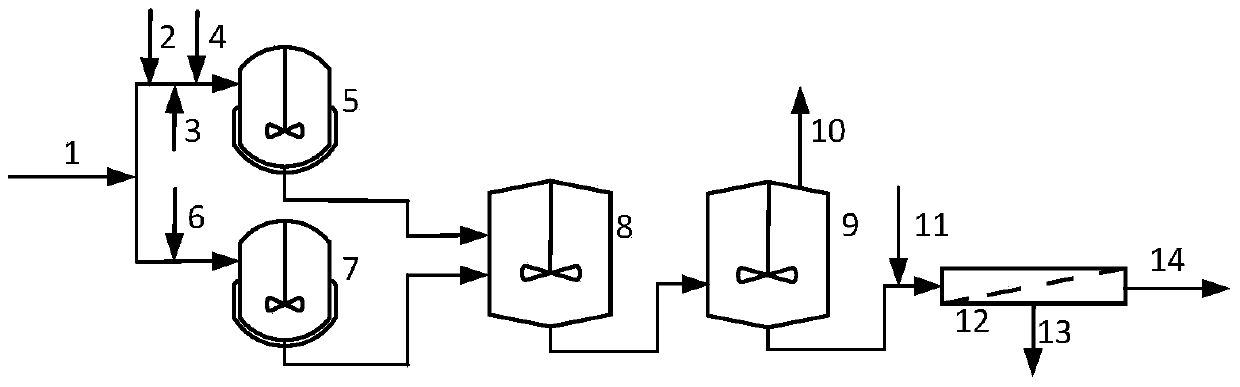

[0044] Such as figure 1 Shown, the embodiment of a kind of excess activated sludge depth reduction method of the present invention is as follows:

[0045] Step 1: The remaining activated sludge 1 is divided into two streams, which are subjected to hot alkali process treatment and Fenton process treatment respectively.

[0046] Fenton process treatment: pump acid 2, iron salt solution 3 and oxidant 4 into excess activated sludge 1 respectively, and enter into oxidation reactor 5. The adjusted pH value of the acid 2 ranges from 3 to 5, and the preferred range is 4 to 5; the acid 2 used to adjust the pH value can be H 2 SO 4 , HCl or HNO 3 One or more of them; iron salt solution 3 can be FeCl 2 , FeSO 4 , Fe(NO 3 ) 2 , FeCl 3 , Fe 2 (SO 4 ) 3 and Fe(NO 3 ) 3 One or several in the solution, preferably FeSO 4 solution. The configuration concentration of the iron salt solution 3 is 2% in terms of Fe mass percentage, and the amount of iron salt (in terms of Fe content)...

Embodiment 1

[0052] Characteristics of residual activated sludge: 10t of sludge in the sludge thickening tank of a sewage treatment plant biochemical treatment process, the sludge index is: the concentration of mixed suspended solids (MLSS) is 30.5g / L (water content 96.95%), the mixed liquid is volatile The suspended solids concentration (MLVSS) was 24.6g / L.

[0053] The implementation steps of the above-mentioned residual activated sludge treatment are as follows:

[0054] Step 1: The remaining activated sludge 1 is subjected to hot alkali process treatment and Fenton process treatment respectively. The ratio of hot alkali process and Fenton process to treat excess activated sludge is determined by process parameters, and the ratio is 1:0.3.

[0055] Fenton process treatment: After pumping acid 2, iron salt solution 3 and oxidant 4 into the remaining activated sludge 1, they are sent to the oxidation reactor 5; the pH value is adjusted to 4, and the acid used to adjust the pH value is H ...

Embodiment 2

[0062] Characteristics of residual activated sludge: 10t of sludge in the sludge thickening tank of a sewage treatment plant biochemical treatment process, the sludge index is: the concentration of mixed suspended solids (MLSS) is 30.5g / L (water content 96.95%), the mixed liquid is volatile The suspended solids concentration (MLVSS) was 24.6g / L.

[0063] The implementation steps of the above-mentioned residual activated sludge treatment are as follows:

[0064] Step 1: The remaining activated sludge 1 is subjected to hot alkali process treatment and Fenton process treatment respectively. The ratio of hot alkali process and Fenton process to treat excess activated sludge is determined by process parameters, and the ratio is 1:0.5.

[0065] Fenton process: After pumping acid 2, iron salt solution 3 and oxidant 4 into the remaining activated sludge 1, they are sent to the oxidation reactor 5; the pH value is adjusted to 5, and the acid used to adjust the pH value is H 2 SO 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com