Industrial robot automatic processing method and device for logistics system

A technology of industrial robots and automation devices, applied in packaging, packaging machines, transportation and packaging, etc., can solve problems such as the influence of workers' code scanning efficiency, the location of stickers is not fixed, and the difference between front and back of stickers, etc., to achieve precise process control and reduce The effect of enterprise labor volume and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

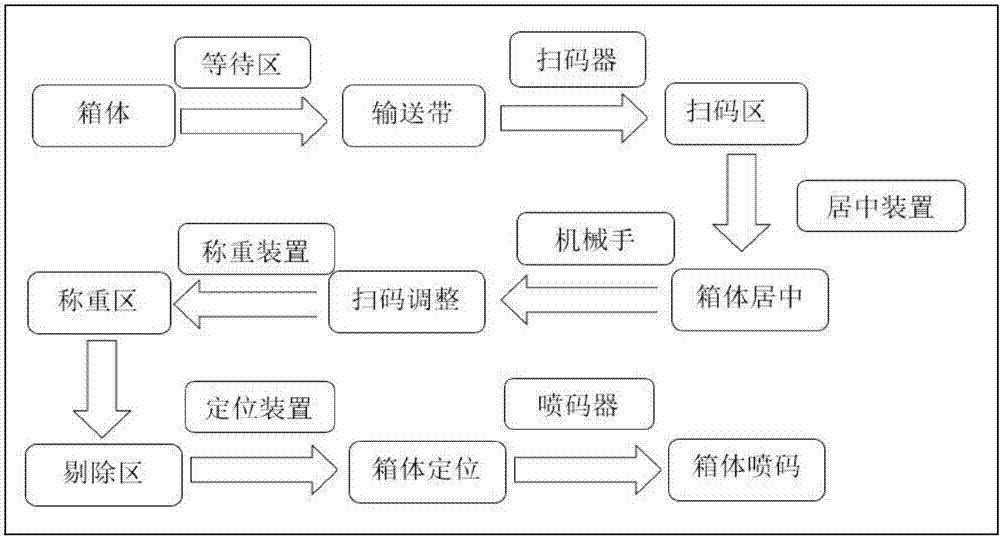

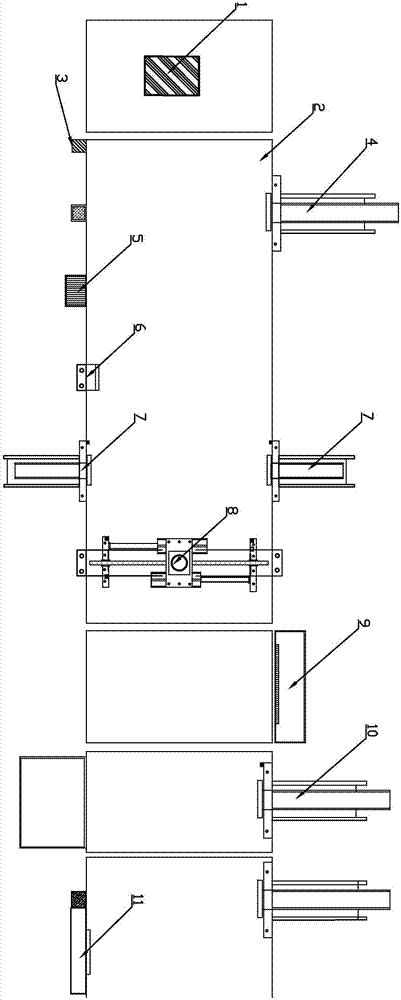

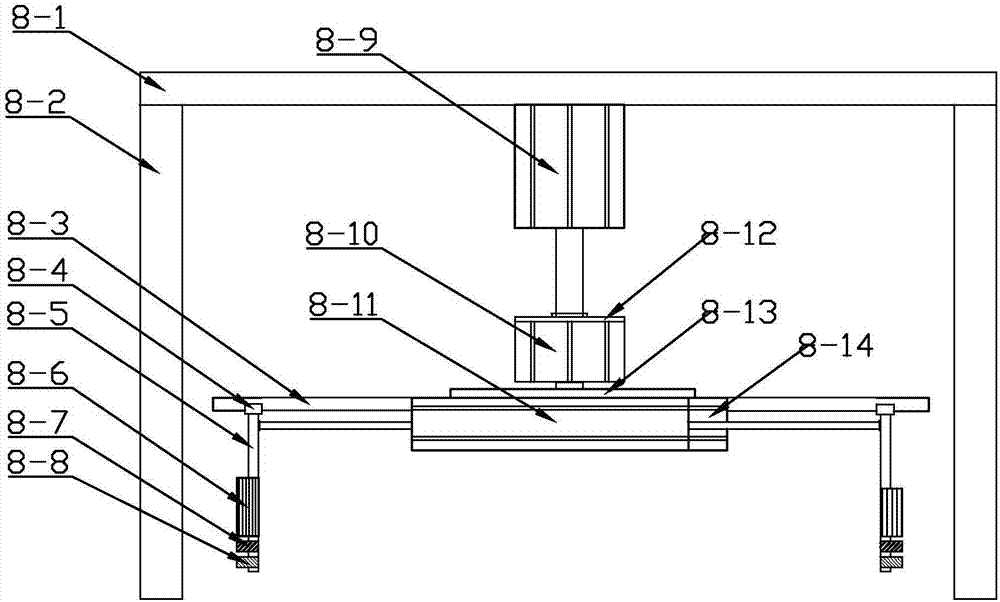

[0038] Specifically, such as Figure 1-Figure 3 The shown industrial robot automatic processing method for the logistics system includes the following steps:

[0039] (1) Waiting for the box; the box is manually placed on the conveyor belt, enters the waiting area for buffering, and is ready to enter the assembly line device. The waiting area is the preparation stage of the entire assembly line. Before the box enters the assembly line, it first passes through the waiting area. The waiting area passes through the photoelectric The switch detects the distance between the two boxes. When the distance between the two boxes is less than the set value, the transmission will stop and the box will stop in the waiting area. When the distance between the two boxes is greater than or equal to the set value, the transmission will continue Run, the box moves forward and enters the next step;

[0040] (2) Alignment and scanning code: After the box enters the conveyor belt, it is first alig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com