Movable type nylon wheel wire drawing machine used for hardware processing

A technology of wheel wire drawing machine and nylon wheel, which is applied in the direction of metal processing equipment, manufacturing tools, grinding racks, etc., can solve the problem of inability to monitor the working status of the wire drawing machine in real time, unable to ensure efficient and stable operation, and low processing efficiency of hardware parts, etc. Problems, to achieve the effect of improving wire drawing efficiency, improving safety and accuracy, and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments, but at the same time it is explained that the protection scope of the present invention is not limited to the specific scope of this embodiment. All other embodiments obtained below all belong to the protection scope of the present invention.

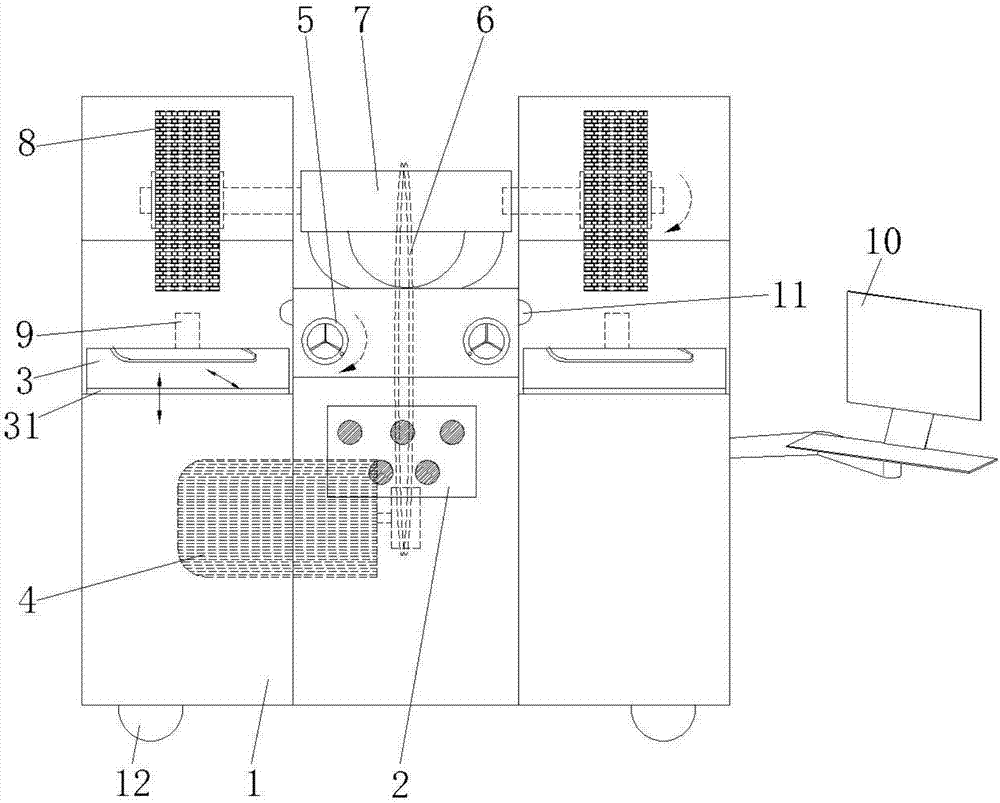

[0024] Such as figure 1 As shown, a movable nylon wheel wire drawing machine for metal processing in this embodiment includes a frame 1, a control panel 2, a workbench 3, a motor 4, a crank handle 5, a triangle belt 6, and a connecting bridge 7 , Nylon wheel 8, display 10, vision sensor 11 and pulley 12.

[0025] The connection relationship of the above-mentioned components is as follows: the inside of the frame 1 is provided with a motor 4, and the motor 4 is connected with the control panel 2 on the surface of the frame 1; the motor 4 drives the connecting bridge 7 to rotate through the triangle belt 6 , the two ends of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com