Rice polishing machine

A polishing machine and rice technology, which is applied in the fields of application, grain finishing, cleaning methods and utensils, etc., can solve the problems of uneven polishing of rice, achieve comprehensive polishing effects, avoid collisions, and reduce the probability of broken rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

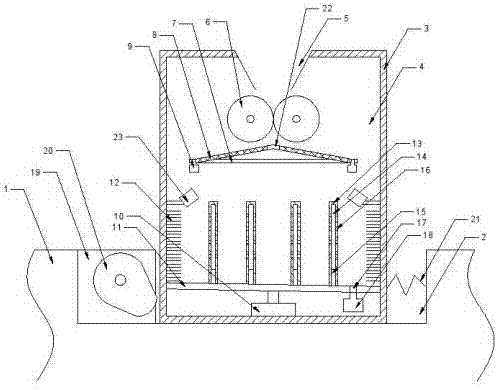

[0018] The reference signs in the drawings of the description include: base 1, chute 2, box body 3, processing chamber 4, feed port 5, gear 6, slide rail 7, screen 8, collection box 9, rotating motor 10, Disc 11, bristle 12, pole 13, air chamber 14, blower fan 15, exhaust hole 16, through hole 17, rice box 18, auxiliary motor 19, cam 20, stage clip 21, discharge port 22, sprayer 23.

[0019] The embodiment is basically as attached figure 1 Shown: a polishing machine for rice, including a base 1, a chute 2 is arranged on the base 1, and a box body 3 is slidably connected to the chute 2; The intermittent mechanism of displacement, the intermittent mechanism comprises auxiliary motor 19 and clip spring 21; 21 is located between the right end of the chute 2 and the casing 3 .

[0020] The box body 3 is provided with a cylindrical processing chamber 4, and the top of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com