Functional air filtering material

An air filter material and functional technology, applied in the field of materials, can solve problems such as environmental protection risks and poor filtration performance, and achieve the effects of light weight, high porosity, and enhanced air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A functional air filter material is composed of a base material and an antibacterial electrospinning nanofiber layer, and the antibacterial agent in the antibacterial electrospinning nanofiber layer is a biological antibacterial agent.

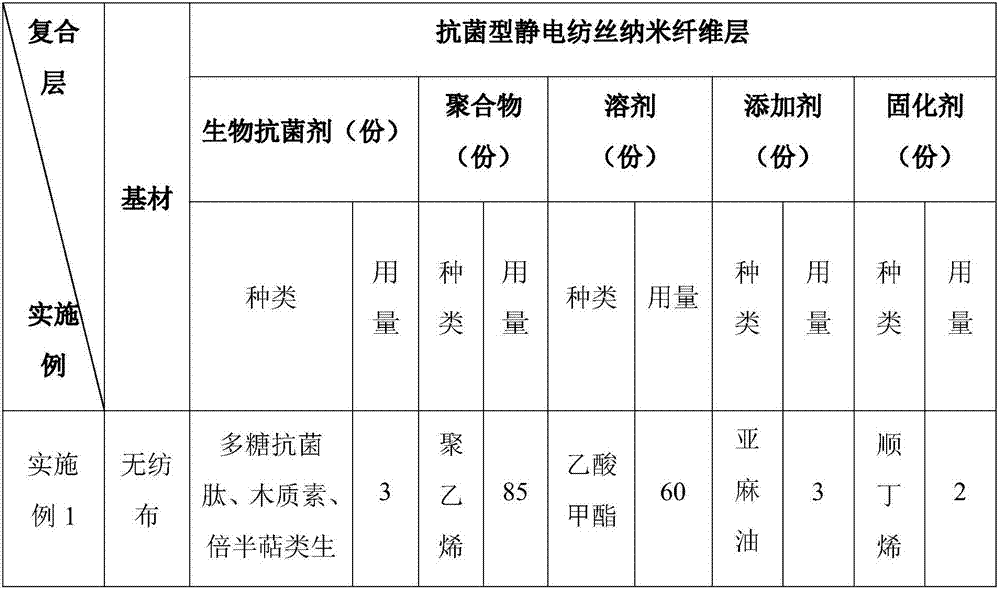

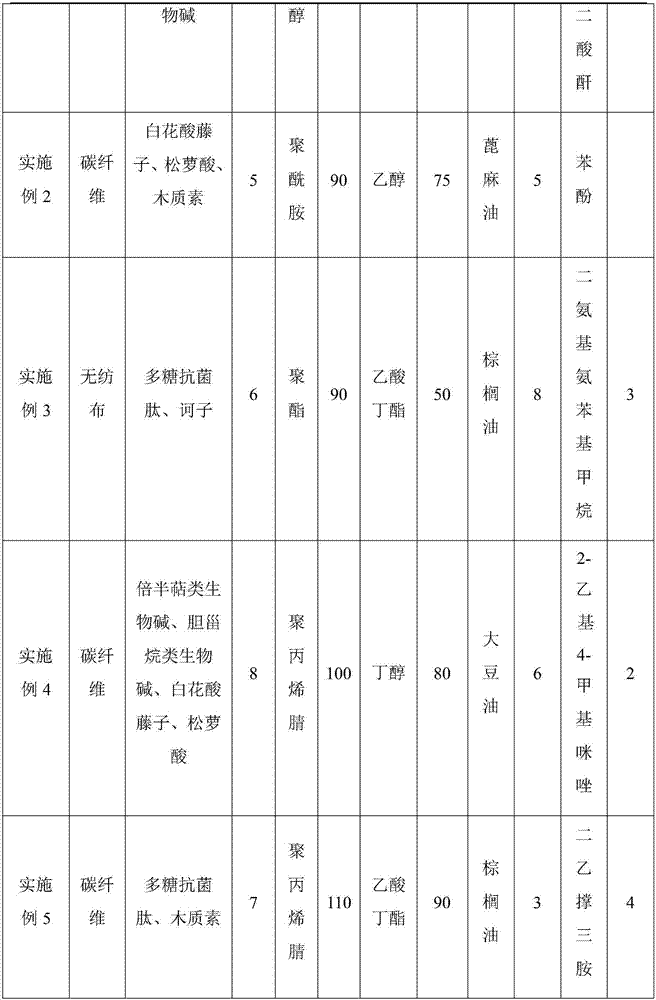

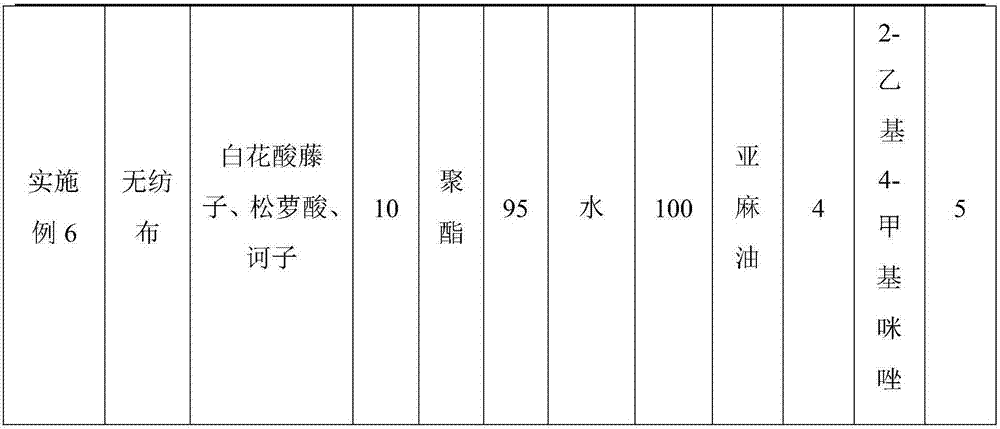

[0026] The specific parameters of the functional air filter material of Examples 1 to 6 are listed in the form of a table, specifically in Table 1:

[0027] The specific parameters of the functional air filter material of table 1 embodiment 1~6

[0028]

[0029]

[0030]

[0031] The preparation method of described functional air filter material, comprises the steps:

[0032] (1) Preparation of spinning solution: polymers, antibacterial agents, additives and solvents are blended in proportion by melting or dissolving, fully stirred and ultrasonically dispersed to form a homogeneous solution;

[0033] (2) Electrospinning: Under the conditions of 18-35°C and relative humidity of 20-60%, the electrospinning solution and the curin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com