Washing method of film used in leachate treatment process

A treatment process and leachate technology, applied in special treatment targets, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of easy re-clogging of membranes for cleaning, long cleaning time, and shortened cleaning cycles, and achieve effective sterilization. and dirt removal, bacterial inhibition and chelation, excellent wetting and detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

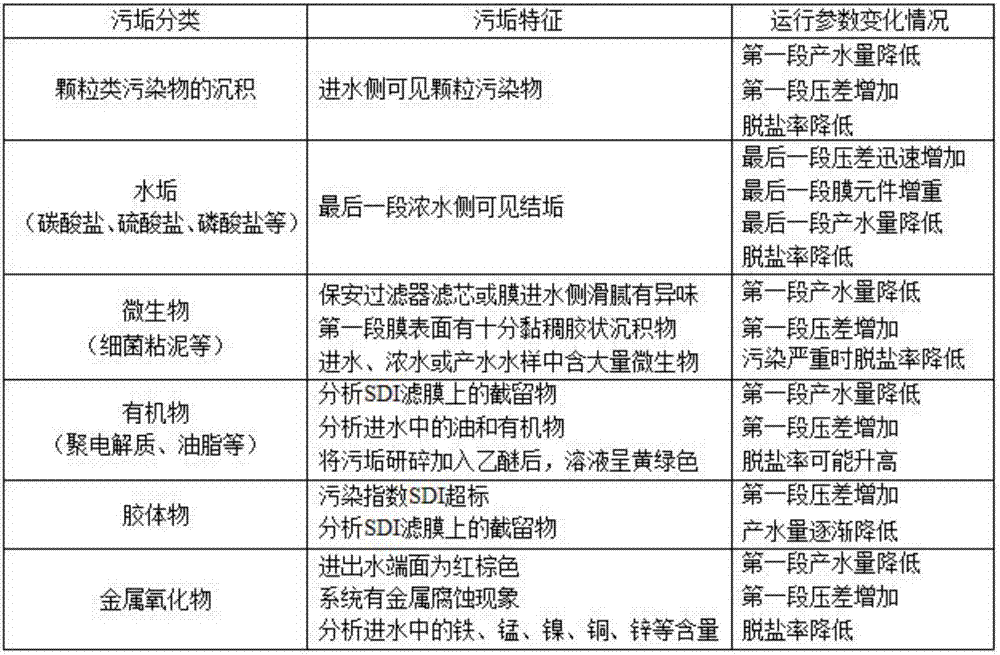

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] 1. Prepare cleaning solution:

[0062] (1) Pre-wash alkaline cleaning solution: inject 200L of reverse osmosis product water into the reverse osmosis chemical cleaning tank, then add 5-7L of 50% NaOH solution and 500g fatty alcohol polyoxyethylene ether to supplement the reverse osmosis product water Put the volume in the reverse osmosis chemical cleaning tank to 500L, stir evenly, measure the pH value, if the pH value is less than 11.5-12.0, add NaOH solution to make the pH value of the cleaning solution 11.5-12.0, and use the bag filter on the reverse osmosis machine filter.

[0063] (2) Alkaline cleaning solution: Dissolve 5kg of tetrasodium ethylenediaminetetraacetic acid, 5kg of sodium tripolyphosphate and 5g of sodium polyacrylate in 20L of reverse osmosis product water in the dissolving tank, and then add about 200L of reverse osmosis Produce water in the reverse osmosis chemical cleaning tank. Finally, add 5-7L of NaOH solution with a concentration of 50% and ...

Embodiment 2

[0078] Example 2 - when the reverse osmosis membrane is subject to class A pollution:

[0079] There is a problem in the No. 4 reverse osmosis unit (RO4) of the leachate treatment plant of the domestic waste landfill site: the conductivity of the product water and the pressure of the main pipe continue to rise, the conductivity of the product water is 1006us / cm, the pressure of the main pipe is 40.0bar, and the pressure of the branch pipe is 44.5 bar; The clean water recovery rate keeps decreasing, the clean water output drops from 10.7t / h to 9.4t / h, and the clean water recovery rate is 74.0%, the data shows that the membrane is seriously clogged.

[0080] (1) Shut down and rinse once and wash once with water to clean the residual sewage during operation;

[0081](2) Use a pre-washing alkaline cleaning solution for preliminary cleaning, and circulate the cleaning for 30 minutes to wash out the loose inorganic dirt and microorganisms on the surface of the membrane. This step is...

Embodiment 3

[0085] Example 3 - when the reverse osmosis membrane is subject to C pollution:

[0086] Membrane plugging occurred in No. 5 reverse osmosis unit (RO5) of the leachate treatment plant of domestic waste landfill: the pressure of the main pipe continued to rise to 41.0 bar, and the pressure of the branch pipe rose to 44.5 bar; the recovery rate of clean water continued to decrease to 72.8%. The output of clear water has dropped from 10.1t / h to 9.1t / h, and the data shows that the membrane has been severely clogged.

[0087] (1) Clean with acidic cleaning solution, cycle cleaning for 30 minutes, soak for 30 minutes, perform 2-5 times of cleaning and soaking operations; control the temperature at 38-40°C, monitor the pH value and color of the cleaning solution every 15 minutes , The degree of turbidity, when the cleaning solution is unqualified, add acid solution or replace it in time;

[0088] (2) Drain the cleaning solution after cleaning, rinse with reverse osmosis water until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com