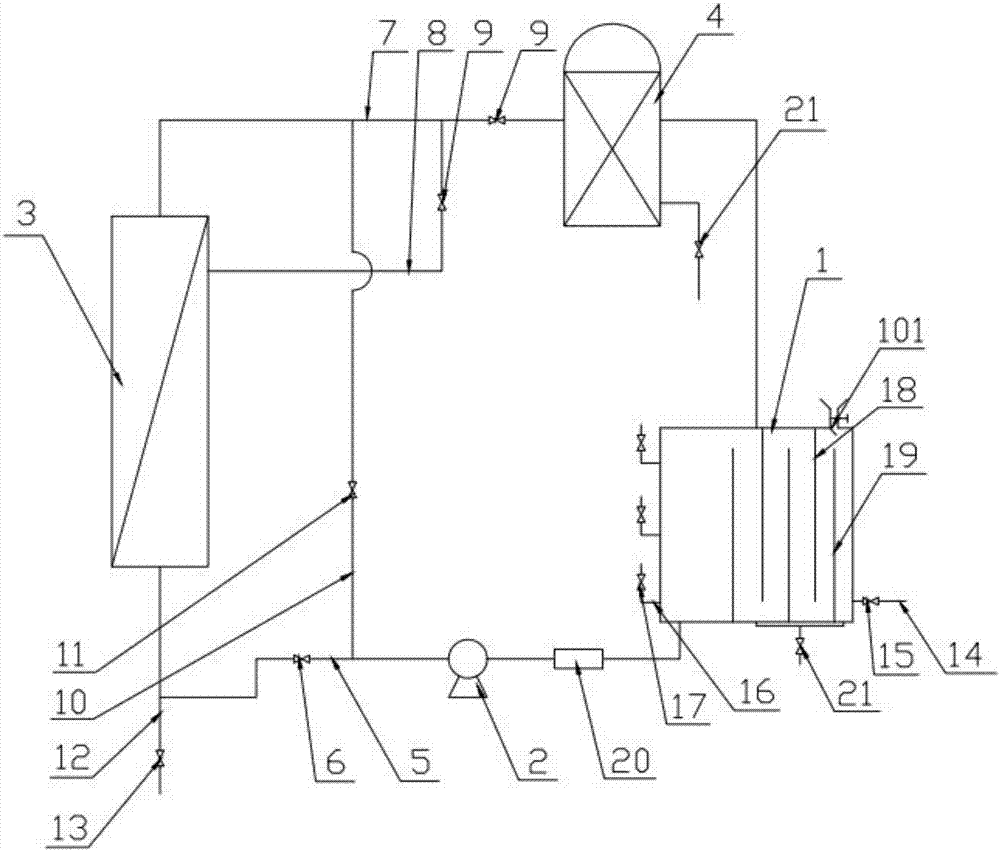

Iron pollution micro-filtration/ultra-filtration film cleaning equipment and cleaning method

A cleaning equipment and iron pollution technology, applied in the field of membrane pollution cleaning, can solve the problems of reduced water supply reliability, increased cleaning frequency, increased operating costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0041] 1. The ultrafiltration of a reclaimed water plant operates in a constant flow mode, and the flux is set at 43L / m 2 *h, the initial pressure is 0.1MPa, when the operating pressure reaches 0.16MPa, EFM (Enhanced Flux Maintenance) cleaning is performed. The EFM cleaning cycle is 3 to 5 days, and the chemical cleaning cycle is 2 to 3 months. The inner coating of the sodium hypochlorite storage tank was corroded, and the iron in the tank was dissolved, and the ultrafiltration system was carried out with the dosing of the chemical solution, resulting in the ultrafiltration system being polluted by iron, and the pollution of the membrane module was mainly iron pollution. The cleaning effect of routine use of citric acid is not good, the membrane system is running at high pressure, the pressure after cleaning is 0.12MPa, the EFM cleaning cycle is shortened to 12h, and the chemical cleaning cycle is shortened to half a month.

[0042] Adopt cleaning method of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com