Potato planter capable of forming inverted-W type ridges, conducting fertilization, conducting film mulching and covering all film surfaces with soil

A potato and film surface technology, which is applied in plant protection, plant protection covers, agricultural machinery and tools, etc., can solve the problems of labor-consuming, time-consuming, slow sowing speed, low efficiency and other problems of manual seedling placement, so as to improve operating efficiency and save labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

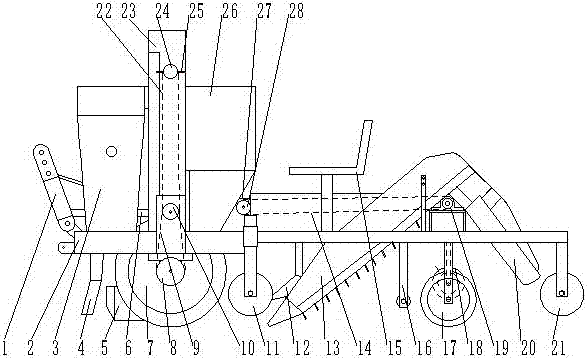

[0009] Example 1, see figure 1 In the frame (2), a suspension frame (1) is arranged at the left end of the frame (2), a fertilizer box (3) is arranged at the upper end of the frame (2), a fertilizer shovel (4) is arranged at the lower end of the frame (3), and a fertilizer box (3) ) There is a seed protection slot (23) at the right end, a seed sprocket (24) and a seed chain (22) are arranged on the seed protection groove (23), and a seed scoop (25) is arranged on the seed chain (22) , A ditching shovel (5) is arranged at the lower end of the seed guard (23), a ground wheel (7) is arranged on the frame (2) at the lower end of the seed guard (23), and a large sprocket is arranged on the ground wheel (7) (8) A small sprocket (10) is provided on the upper end of the large sprocket (8), a ground wheel chain (9) is provided on the small sprocket (10), and a seed potato box is provided at the right end of the seed protection slot (23) (26), the frame (2) at the lower end of the seed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com