Belt tightener for a safety belt system

A technology of seat belts and tensioners, applied in the direction of seat belts, belt tensioners, transportation and packaging in vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

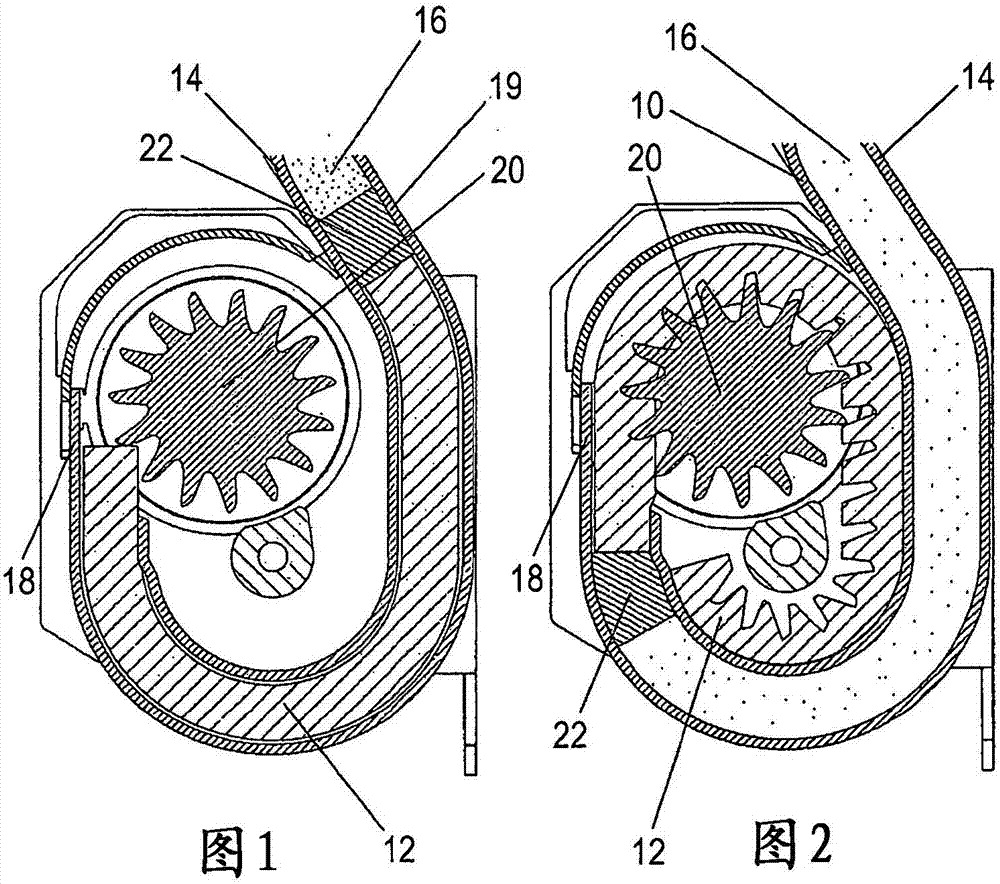

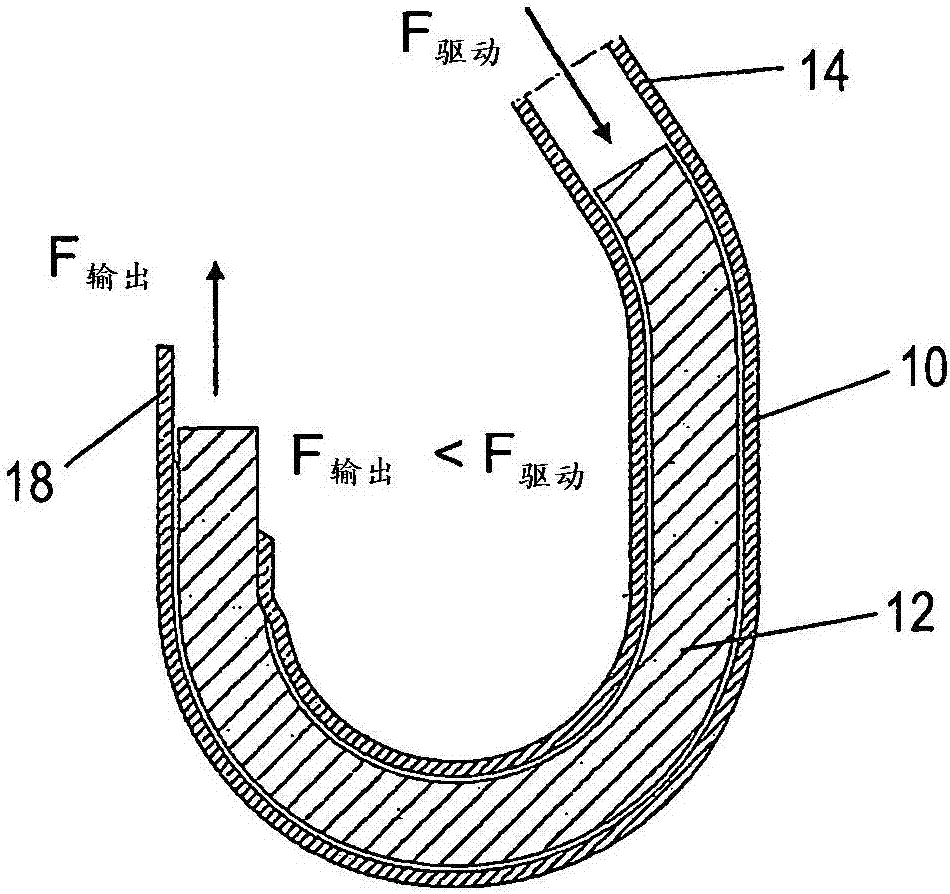

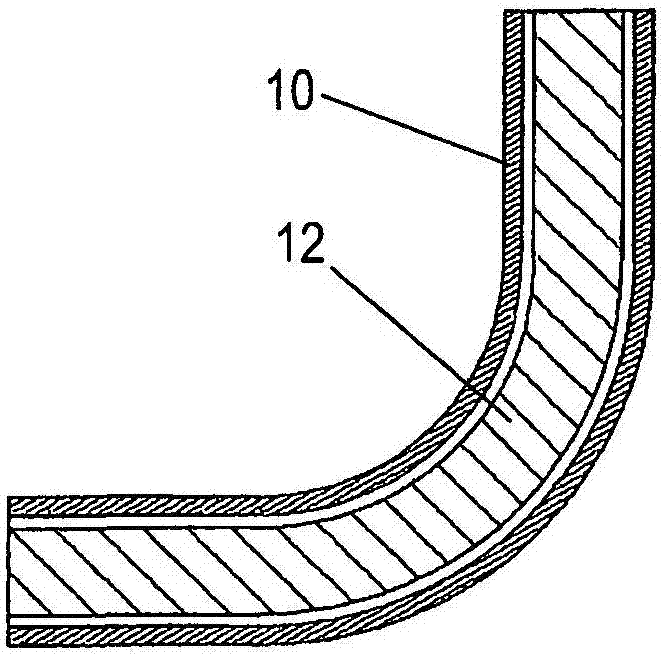

[0035] in figure 1 Shows the driving device of the seat belt tensioner for the seat belt retractor. The drive device has a force transmission element 12 movably arranged in the tensioner tube 10. The force transmission element 12 is made of a substantially deformable material.

[0036] On the first end 14 of the tensioner tube 10, in a section of the tensioner tube 10 serving as a pressure chamber, the compressed gas 16 may be provided by a gas generator (not shown). The second end of the tensioner tube 10 is oriented to the outer toothing of a rotatably supported drive wheel 20, which is coupled to a belt spool of a belt retractor (not shown).

[0037] An elastic sealing element 22 is arranged between the compressed gas 16 and the force transmission element 12, which can also move in the tensioner tube 10. The sealing element 22 rests on the force transmission element 12, but a small distance can also be set. The sealing element 22 holds the compressed gas 16 on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com