Novel high power water load

A high-power, water-loaded technology, applied to waveguide devices, electrical components, circuits, etc., can solve problems such as the inability to meet high-power requirements, small power capacity of the improved radiation water load, and slow water flow rate, etc. The effect of excessive pressure loss, reducing electromagnetic radiation, and increasing the flow rate of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

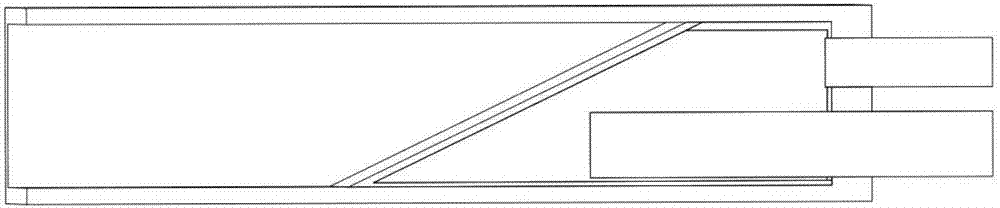

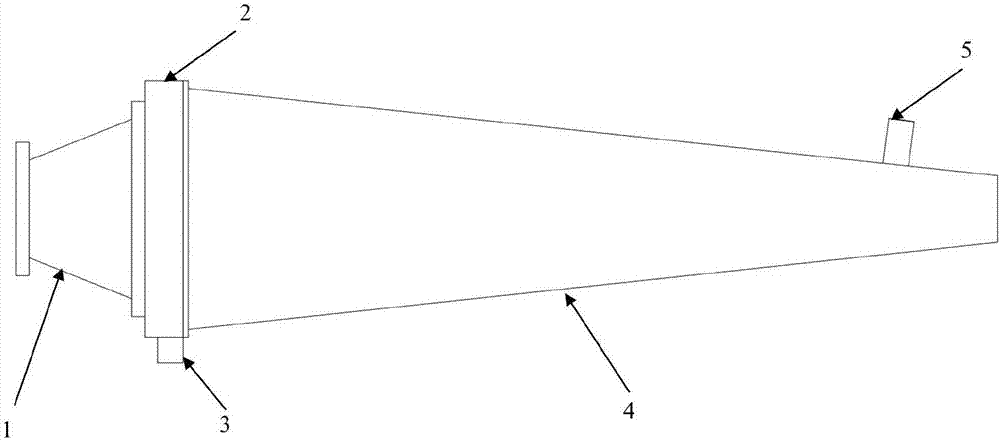

[0067] In the above-mentioned present embodiment, the spiral water chamber 7 with spiral flowing water as a microwave absorber is formed by coiling, bonding, and shaping the water channel processed by polytetrafluoroethylene material according to the cone structure model, in which the waveguide radiation horn The inner radius of the mouth 1 is 16mm, the inner radius of the outlet is 50mm, and the height is 100mm; the inner radius of the base 2 and the rear end of the spiral water chamber 7 is 50mm; the height of the water chamber is 500mm, the outer radius of the polytetrafluoroethylene material water pipe is 7mm, and the inner radius is 5mm; the height of the terminal short circuit block 6 is 100mm.

[0068] First, the inner radius of the water pipe is calculated according to the complex permittivity of water and the working center frequency combined with formula (5). When the theoretical calculation result is 5mm, the amplitude of the electromagnetic wave electric field in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com